Our Standard Certifications

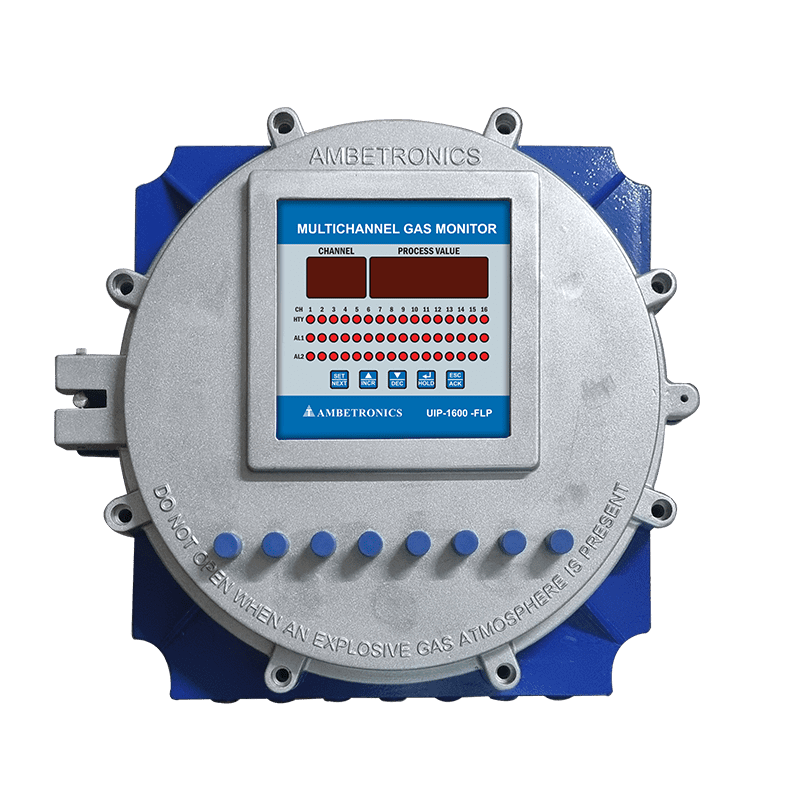

16 Channel Universal Data Logger | UIP-1600-FLP

The UIP-1600-FLP is a state-of-the-art 16 Channel Universal Data Logger featuring the latest microcontroller technology for enhanced accuracy. With 16 universal input channels supporting thermocouples (types J, K, R, S, T, B, N), RTD (PT-100), and 4-20mA programmable by the user, it offers easy on-field calibration through a front panel membrane keypad. The device supports remote acknowledgment for relays, with optional RS-485 Modbus serial port. Designed for diverse applications including Fertilizer Plants, Oil & Gas Industries, Refineries, and more, this device holds multiple certifications, including CIMFR, PESO, and BIS Mark License. It complies with Zone 1 and Zone 2 standards, ensuring safety in hazardous environments.

1. Advanced Technology: 16 Channel Universal Data Logger Utilizes the latest microcontroller-based technology for superior accuracy in data scanning and logging.

2. Flexible Input Channels: 16 universal input channels supporting thermocouples (types J, K, R, S, T, B, N), RTD (PT-100), and 4-20mA programmable by the user.

3. On-Field Calibration: Easy online field calibration facilitated by a front panel membrane keypad, ensuring convenient and precise adjustments.

4. User-Programmable Settings: Allows users to program channel scan time (1-240 sec), logging interval (1-9999 sec), based on specific application requirements.

5. Remote Acknowledgment: 16 Channel Universal Data Logger features remote acknowledgment capabilities for relays, enhancing control and monitoring from a distance.

6. Certifications and Compliance: Holds CIMFR, PESO, and BIS Mark License certifications, ensuring compliance with safety and quality standards. Suitable for Zone 1 and Zone 2 environments, with gas group IIA, IIB & IIC compliance.

7. Dual Set Points with Relays: Equipped with two independent user-programmable set points for each channel, featuring four common relay outputs. Remote acknowledgment facility for relays is available.

Technical Specifications:

1. Display: 4-digit 13mm height Red LED 7-segment display for ‘Process Value’ and 2-digit 13mm height Red LED 7-segment display for ‘Channel Number’ indication.

2. Input Type: 16 universal input channels supporting thermocouples (types J, K, R, S, T, B, N), RTD (PT-100), and 4-20mA programmable by the user.

3. Control Action: Low/High control action for Alarm 1 – Low & Alarm 2 – High, user-programmable for specific application needs.

4. Keypad Interface: Settings accessible via a 5-key keypad on the front panel for Panel Mount & WP models; push button keys for FLP model.

5. LED Indication: 8/16 Red LEDs for Alarm 1, Alarm 2, and Healthy indications for CH-1 to CH-8/CH-1 to CH-16.

6. Electrical Supply: Supports a wide voltage range of 90 to 270 VAC (50Hz) or 110 VDC to 270VDC, with a frequency of 50Hz.

7. Operating Environment: Operates within an extensive temperature range of -40°C to 85°C with a relative humidity below 95%RH (non-condensing).

8. Performance Features: Offers monitoring of errors with specific display indications, adjustable scan time (1 to 240 sec), and logging interval (1 to 9999 sec) to meet diverse monitoring needs.

9. Flameproof Housing: Features a robust cast Aluminum LM6 Alloy enclosure with IP-66 protection. Approved by CIMFR and PESO, meeting stringent safety standards.

10. Dimension and Mounting: Dimensions of 448 (H) x 431 (W) x 210 (D) mm, weighing approximately 12 kg. Suitable for wall or stand mounting.

| Pharmaceutical Warehouse Monitoring | ISO Certification Record Keeping and Validation Processes |

| Online Profile Recording for Oven, BOD, Incubator, and Humidity Chamber | Pharmaceutical Warehouse Room Mapping |

| Blood Bank Monitoring | Pharmaceutical Process Validation with Graphs and Excel Reports for Autoclaves |

| Monitoring Winding Temperatures in Generators, Bearings, Motors, and Transformers | Heat Profile Monitoring in Furnaces and Foundries for Heat Treatment |

| Primary and Auxiliary Temperature Scanning of Boilers | Monitoring in Chemical and Hazardous Areas Where Data Monitoring is Crucial |