Safety in Semiconductor Industry

Welcome to the Application Page of Ambetronics where we are sharing you our best safety solution in semiconductor industry. Our Smart Gas Detector offers reliable detection of gases like SiH4, BCl3, PH3, CH4, H2, HF, N2O, NH3 in various applications. With its advanced features, including smart pluggable sensor modules, configurable alarm set points, and optional communication ports, it ensures early detection of gas leaks and enhances workplace safety.

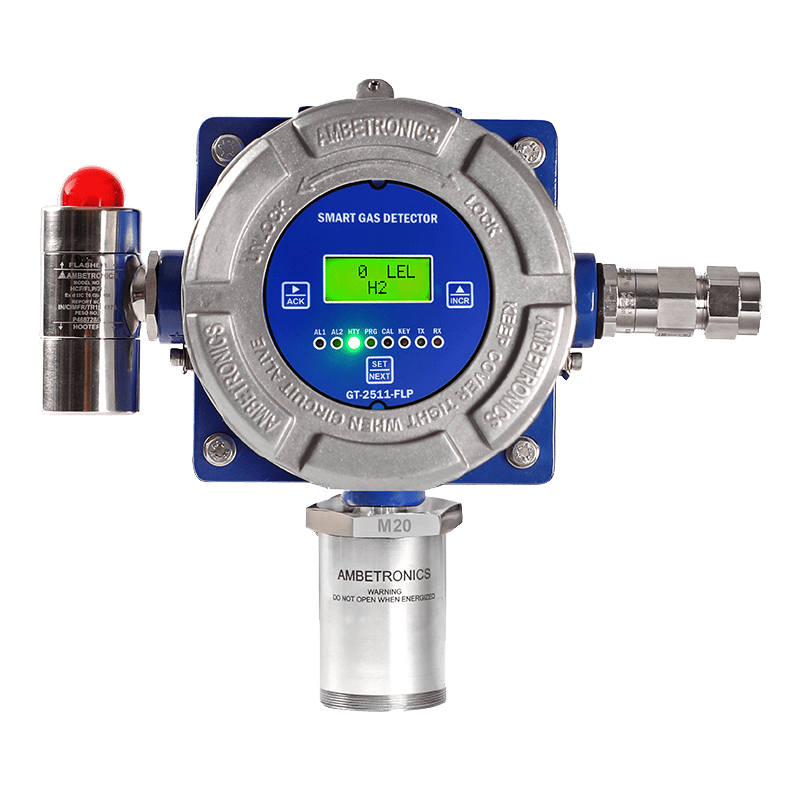

Introducing the GT-2511-FLP: Advanced Gas Detection for Semiconductor Industry

In the dynamic world of semiconductor manufacturing, safety and precision are paramount. Meet the GT-2511-FLP Gas Leak Detector, the cutting-edge solution designed to ensure the utmost safety and efficiency in semiconductor facilities. With its advanced features and robust design, the GT-2511-FLP offers comprehensive gas detection capabilities, enabling early detection of SiH4, BCl3, PH3, CH4, H2, HF, N2O, NH3. From its smart pluggable sensor modules to its user-friendly interface and precise detection capabilities, this detector is tailored to meet the unique needs of semiconductor environments. Trust the GT-2511-FLP to safeguard your operations and personnel, providing reliable gas detection for the semiconductor industry.

GT-2511-FLP

smart Gas Detector

Features of Ambetronics Gas Detector

Comprehensive Gas Detection

Capable of detecting a wide range of gases, including SiH4, BCl3, PH3, CH4, H2, HF, N2O, NH3, ensuring comprehensive monitoring of potential hazards.

Smart Pluggable Sensor Module

Provides flexibility with interchangeable sensor modules for listed gases in the catalogue allowing for customized gas detection configurations.

Data Management and Maintenance

Calibration data, alarm data, offset data, and output current data are saved within the sensor module, simplifying maintenance and servicing tasks.

Highly Resistant Design

Resistant to poisoning and etching, ensuring reliable performance even in harsh industrial environments.

User-Friendly Interface

Features a 2-line, 4-digit 8 mm (H) seven-segment LED display and 8 LEDs to indicate the status of the instrument, providing clear and intuitive feedback.

Alarm and Notification System

Provides indication for sensor open, over-range, sensor replace, calibration due, calibration fail, and mA loop open, ensuring prompt notification of any issues.

Problems and Solutions:

In the semiconductor industry, ensuring safety and operational efficiency is paramount amidst the complex manufacturing processes. To tackle challenges like gas leaks, contamination, equipment failure, safety compliance, environmental impact, and supply chain disruptions, proactive measures are imperative. Implementing advanced gas detection systems, maintaining stringent cleanroom protocols, adopting predictive maintenance technologies, adhering to safety regulations, embracing eco-friendly practices, and establishing robust supply chain management strategies are vital. By addressing these challenges with effective solutions, semiconductor manufacturers can uphold safety standards, optimize production processes, and navigate the evolving landscape of the industry with resilience and success.

Wafer Fabrication Facilities

The GT-2511-FLP is essential in monitoring toxic and combustible gases emitted during fabrication processes such as chemical vapor deposition (CVD) and plasma etching. It detects gases like SiH4, BCl3, PH3, CH4, H2, HF, N2O, NH3, ensuring early detection of leaks and preventing potential hazards.

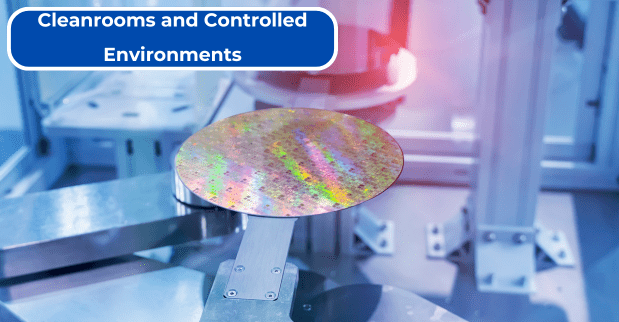

Cleanrooms and Controlled Environments

Continuous monitoring of air quality and detection of contaminants in cleanroom environments is vital. Our gas detector equipped with smart pluggable gas sensor modules provides accurate detection of SiH4, BCl3, PH3, CH4, H2, HF, N2O, NH3 for maintaining a safe working environment.

Gas Cylinder Storage Area

Monitoring of gas storage areas to prevent leaks and ensure safe handling of compressed gas cylinders is crucial. The GT-2511-FLP's highly resistant design and optional alarm relay contacts offer reliable detection of gas leaks, enhancing safety protocols in storage facilities.

Semiconductor Assembly and Packaging Facilities

Continuous monitoring of air quality and detection of contaminants in cleanroom environments is vital. Our gas detector equipped with smart pluggable gas sensor modules provides accurate detection of SiH4, BCl3, PH3, CH4, H2, HF, N2O, NH3 for maintaining a safe working environment.

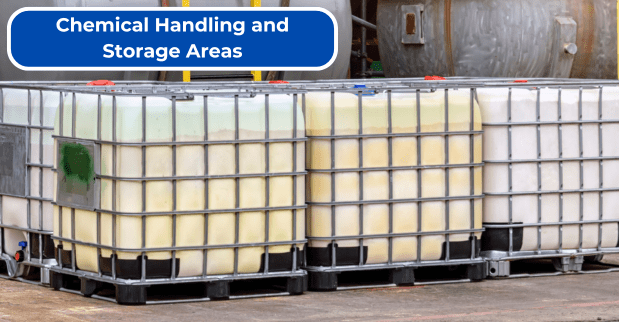

Chemical Handling and Storage Areas

Monitoring of chemical storage areas to prevent leaks and exposure to harmful vapors is essential. Featuring non-intrusive programming and password-protected settings, our gas detector ensures easy maintenance and secure operation in chemical storage facilities.