Ambetronics Ember Detector:

The Ultimate Solution

In the dynamic landscape of industrial safety, Ambetronics introduces the Ember Detector, a cutting-edge solution designed to revolutionize safety measurements in industries and factories. As a leader in the field, we take pride in presenting a state-of-the-art product with advanced features tailored to meet the rigorous demands of diverse industries.

ENHANCE YOUR SAFETY WITH AMBETRONICS EMBER DETECTOR

How Does a Ember Detector Works?

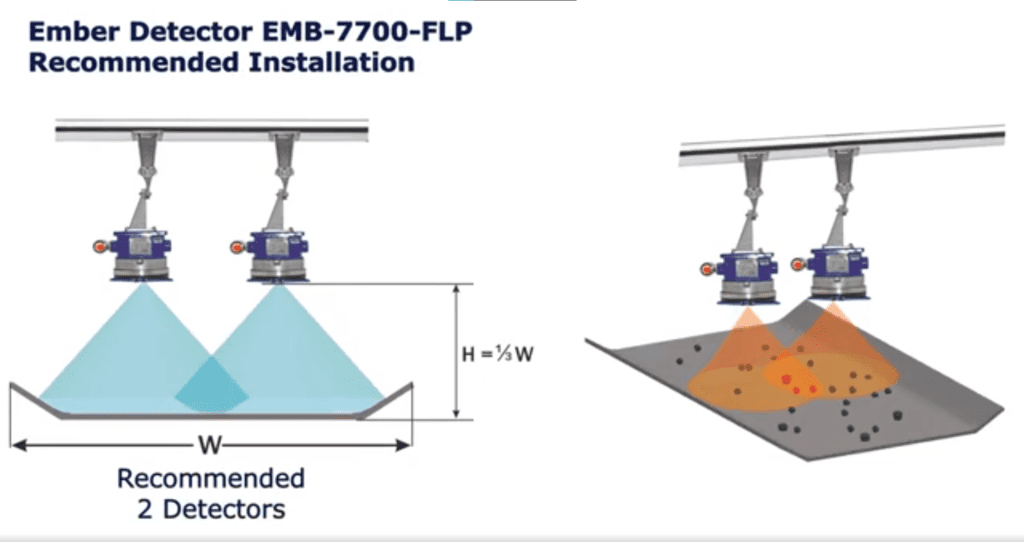

The Ember Detector operates by utilizing cutting-edge IR technology for high-speed ember detection in hazardous industrial environments, featuring an optical cleaning system to prevent dust accumulation, sensitivity selection for zone customization, and multiple output options for flexibility. It ensures accurate and precise detection, low power consumption, and compliance with safety standards, offering additional features like optional connectivity via IoT and mobile alerts for enhanced safety.

Applications of Ember Detector

Conveyors, Silos

Waste Recycling Conveyors

Coal dust conveyance

Escalators

Drying Lines

Extractors

Production & Automation industry

Waste recycling industry

Wood industry: sawdust shavings

Textile industry

Food industry

Pharmaceutical & chemical industry

Why Choose Ambetronics Ember Detector?

When it comes to safeguarding industrial environments and ensuring the well-being of personnel, the Ambetronics Ember Detector stands out as the premier choice. Here's why you should consider this state-of-the-art safety solution:

| 1. Cutting-Edge Technology: The Ember Detector employs high-speed IR technology for rapid and precise ember detection, ensuring a proactive safety approach in industries. | 8. Versatile Output Options: Enjoy flexibility with multiple output options, including three relays for Ember Detection, AUXILIARY, and FAULT, along with 0-20mA or 0-10V outputs. Optional HART protocol and RS-485, MODBUS compatibility provide seamless integration. |

| 2. Tailored for Hazardous Environments: Specifically designed for hazardous settings, the system boasts a flameproof housing certified to Ex d IIC T6 Gb, making it reliable in potentially explosive conditions. | 9. User-Friendly Configuration: Easily program the system via Bluetooth, HART, or RS-485, ensuring user-friendly configurability and hassle-free integration into existing safety frameworks. |

| 3. Optical Cleaning System: The innovative Optical Cleaning System prevents dust and dirt accumulation on the window, guaranteeing clear visibility and sustained performance even in challenging environments. | 10. Comprehensive Connectivity: Optional connectivity via IoT, mobile alert (LoRa/WiFi), and RS-485 communication with MODBUS RTU protocol enables seamless integration into modern industrial communication networks. |

| 4. Accurate Ember Verification: Accuracy is paramount, and the Ember Detector excels in providing accurate and precise ember detection, minimizing false alarms and enhancing operational efficiency. | 11. Optional Features for Enhanced Safety: Choose from optional features like a heat detector extension, date-time stamped event logging, built-in self-test (BIT), and a mobile alert system for additional layers of safety. |

| 5. Low Power Consumption: With a commitment to sustainability, the system features low power consumption, aligning with industry trends towards energy-efficient solutions. | 12. PESO Approved: The Ember Detector holds PESO approval, attesting to its compliance with stringent safety regulations, making it a trusted solution for industrial safety. |

| 6. Sunlight Insensitivity: The detector remains insensitive to sunlight, ensuring consistent performance regardless of varying light conditions, offering adaptability to diverse industrial setups. | 13. Make in India – ISO 9001:2015 Certified: Proudly manufactured in India and ISO 9001:2015 certified, Ambetronics Engineers Pvt. Ltd. ensures a product of the highest quality and excellence. |

| 7. Sensitivity Selection: Tailor the system to specific zones with sensitivity selection, preventing zone crossover detection and ensuring a customized safety solution. |

ENHANCE YOUR SAFETY WITH AMBETRONICS EMBER DETECTOR

FAQs

How does the Ambetronics Ember Detector contribute to safety in industries and factories?

The Ambetronics Ember Detector enhances safety by utilizing high-speed Ember detection through Infrared (IR) technology. It is specially designed for hazardous environments, providing accurate and precise detection in diverse industrial settings.

What makes the Ember Detector suitable for challenging environments in industries?

The Ember Detector is designed with a flameproof housing certified to Ex d IIC T6 Gb, making it ideal for potentially explosive environments. Its robust construction ensures reliability in the presence of conveyors, silos, waste recycling conveyors, coal dust conveyance, escalators, drying lines, and extractors.

Can the Ember Detector operate in sunlight, and what is its power consumption?

Yes, the Ember Detector is insensitive to sunlight, ensuring consistent performance in various lighting conditions. Additionally, it boasts low power consumption, contributing to energy efficiency in industrial operations.

How does the Optical Cleaning System improve the performance of the Ember Detector?

The Ember Detector features an Optical Cleaning System to prevent the accumulation of dust and dirt on the window. This ensures clear visibility and uninterrupted performance, even in environments prone to particulate matter.

What is Ember verification, and how does it enhance detection accuracy?

Ember verification is a feature of the Ember Detector that ensures accurate and precise detection by validating detected embers. This minimizes false alarms and provides a reliable safety net for industries dealing with production and automation, waste recycling, wood processing, textiles, food, and pharmaceuticals.