Carbon Monoxide Gas Detectors - Ambetronics | Manufactured in India

Ensure unparalleled safety in your industries and factories with Ambetronics' Carbon Monoxide Gas Detector. This advanced detection system is designed to swiftly identify even the smallest leaks of Oxygen, Toxic, Combustible, and Volatile Organic Compounds (VOC). With a focus on precision, reliability, and user-friendly features, this detector stands out as a must-have for industrial safety.

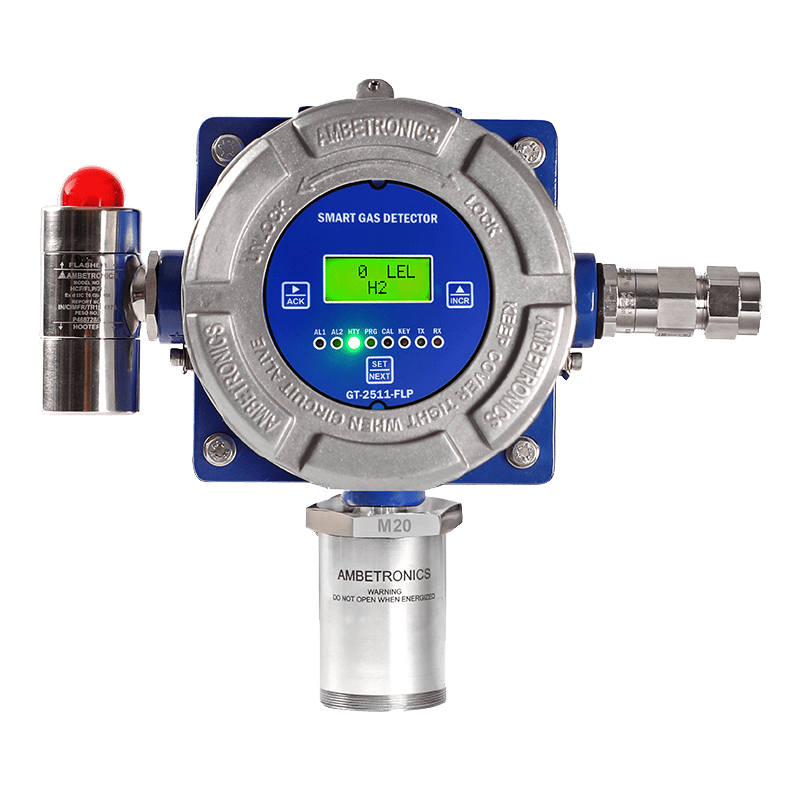

GT-2511-FLP

Smart Gas Detector L.E.D Display

GT-2500-FLP

Smart Gas Detector LCD Display

GT-1033-FLP

2 Wire Loop Powered Transmitter

GT-2511-WP

Smart Gas Detector L.E.D Display

GT-2500-WP

Smart Gas Detector LCD Display

GT-1033-WP

2 Wire Loop Powered Transmitter

Interested in our Carbon monoxide gas detector system?

Our Standard Certifications

Our Carbon Monoxide Gas Detector meets the highest industry standards for safety and reliability. It is certified for use in a wide range of industrial applications, providing peace of mind and security for your workplace.

What is Carbon Monoxide Gas Detector?

Carbon Monoxide (CO) is a silent threat in industrial settings, and timely detection is crucial. Our Carbon Monoxide Gas Detector emerges as a sentinel, providing real-time data to prevent potential disasters.

Features That Set Our CO Gas Detector Apart:

Industrial Standard 4-20mA Output of Carbon Monoxide Gas Detection

The 4-20mA output ensures a standardized communication protocol, allowing seamless integration with existing systems.

Loop Test for Calibration Assurance

Our CO Gas detector also comes equipped with a loop test feature, assuring proper operation without the need for calibration gas.

Easy Programming with Password Protection

Programming the detector is a breeze, thanks to user-friendly interfaces with password protection for added security.

Fast Response and Easy-to-Read Display

A swift response time coupled with a user-friendly display ensures quick and accurate interpretation of gas concentration levels.

Plug-N-Play Sensor Module Replacement

On-field sensor module replacement is made simple with our Plug-N-Play design, reducing downtime and maintenance costs.

Reverse Polarity Protection

Worried about incorrect power connections? Our detectors feature reverse polarity protection for added safety.

Interested in our Carbon monoxide gas detector system?

No Additional Power Required

Efficiency meets sustainability as our detectors operate without the need for additional power, reducing overall energy consumption.

Applications of Carbon Monoxide Gas Detector

Synthesis Gas (Syngas) Production

Semiconductor Manufacturing

Medical Device Manufacturing

Plastic and Polymer Industry

Iron and Steel Industry

Environmental Monitoring

Methanol Production

Laboratory Synthesis

Petrochemical Processes

Water Purification

Food Packaging

Chemical Synthesis

Specification of Carbon Monoxide Gas Detector

Sensors and Detection Method

To enhance user confidence, our detectors come equipped with robust error monitoring features. Whether it's sensor breaks, over-range situations, or output current issues, our detectors provide clear indications, ensuring quick response and resolution.

Accuracy and Electrical Specifications

In addition to specific error monitoring, our detectors offer a range of general features, including adjustable current settings, selectable upscale and downscale currents, and optional alarm relay contacts. This flexibility makes our detectors adaptable to a variety of operational scenarios.

Optional Accessories for Enhanced Performance

To further elevate performance, consider optional accessories such as certified power supplies and CO gas sampling systems.

Why Choose Electrochemical Sensors?

Electrochemical sensors, with their superior stability and accuracy, stand as the preferred choice for industries prioritizing safety.Hence, Detecting Carbon Monoxide Gas in a Frequent Time to Avoid Gas Leaks early

Other Range of Gases:

ELECTROCHEMICAL SENSOR TECHNOLOGY

| SR. NO | GASES | RANGE | UNIT | RESOLUTION |

|---|---|---|---|---|

| O1 | Oxygen (O2) | 25 | %Vol. | 0.01 |

| TOXIC GASES | ||||

| NT1 | Nitrogen (N2) | 75 to 100 | %Vol. | 0.1 |

| T1 | Ammonia (NH3) | 100 | PPM | 1 |

| T2 | Ammonia (NH3) | 1000 | PPM | 1 |

| T3 | Bromine (Br2) | 10 | PPM | 0.01 |

| T4 | Carbon Monoxide (CO) | 1000 | PPM | 1 |

| T5 | Carbon Monoxide (CO) | 2000 | PPM | 1 |

| T6 | Chlorine (CL2) | 10 | PPM | 0.01 |

| T7 | Ethylene Oxide (ETO) | 100 | PPM | 1 |

| T8 | Hydrogen (H2) | 2000 | PPM | 1 |

| T9 | Hydrogen Bromide (HBr) | 100 | PPM | 1 |

| T10 | Hydrogen Chloride (HCL) | 100 | PPM | 1 |

| T11 | Hydrogen Cyanide (HCN) | 100 | PPM | 1 |

| T12 | Hydrogen Fluoride (HF) | 10 | PPM | 0.01 |

| T13 | Hydrogen Fluoride (HF) | 100 | PPM | 1 |

| T14 | Hydrogen Sulfide (H2S) | 100 | PPM | 1 |

| T15 | Ozone (O3) | 20 | PPM | 0.01 |

| T16 | Phosphine (PH3) | 10 | PPM | 0.01 |

| T17 | Nitrogen Dioxide (NO2) | 20 | PPM | 0.01 |

| T18 | Nitric Oxide (NO) | 250 | PPM | 1 |

| T19 | Sulfur Dioxide (SO2) | 50 | PPM | 0.1 |

| T20 | Sulfur Dioxide (SO2) | 2000 | PPM | 1 |

| NDIR SENSOR TECHNOLOGY | ||||

| N4 | Methane (CH4) | 100 | %LEL | 1 |

Interested in our Carbon monoxide gas detector system?

FAQs

How often should this CO sensors be calibrated?

Regular calibration is recommended every six months to ensure optimal performance.

Can these Gas detectors operate in extreme temperatures?

Yes, our detectors operate efficiently in a temperature range of -15 to +55°C.

Is the display easy to understand for non-technical users?

Absolutely, the display is designed for simplicity, ensuring ease of use for all.

What is the typical response time for the CO detectors?

The detectors boast a response time of less than 10 seconds, providing swift results.

Are the detectors compliant with EMC standards?

Yes, ourCarbon Monoxide Gas detectors comply with IEC – 61000-4 standards for electromagnetic compatibility.