Fixed Oxygen Gas Detector Made for Precise O2 Gas Level Measurement.

Introduction:

GT-2511-WP

Smart Gas Detector with Weatherproof Enclosure

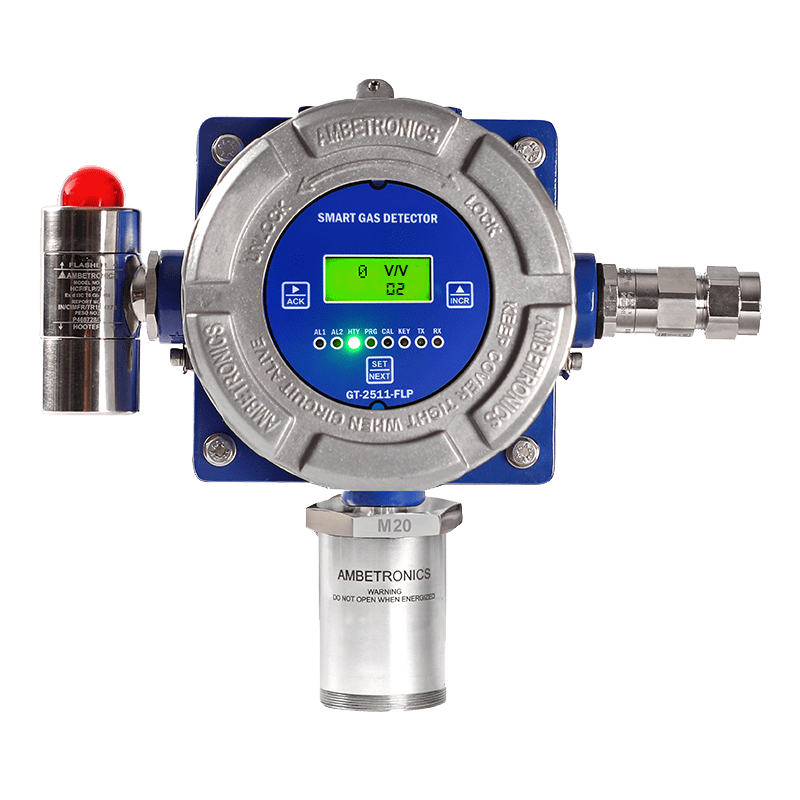

GT-2511-FLP

Smart Gas Detector with Flameproof Enclosure

Understanding the Importance of Oxygen Monitoring: Safeguarding Industries

Oxygen, often taken for granted, plays a pivotal role across diverse industries and applications. In manufacturing plants, laboratories, and confined spaces, its presence is more than a life force—it’s an integral part of operational efficiency. However, the fine balance can easily tip towards risks when oxygen levels deviate. The potential consequences of oxygen deficiencies or excess are not easy to understand; they are tangible threats with far-reaching implications.

Ambetronics Fixed Oxygen Gas Detector: The Ultimate Choice in Gas Detection

The GT-2511-FLP Smart Gas Detector stands as a sentinel, addressing the real-life risks faced by workers daily. Crucial application like chemical processing plant where oxygen levels dip unexpectedly, jeopardizing both the safety of personnel and the integrity of processes. It’s not just a hypothetical risk; it’s a practical challenge that necessitates continuous monitoring. The GT-2511-FLP goes beyond theoretical importance; it’s a practical solution ensuring that the vital element—oxygen—remains a reliable ally, not a latent danger.

Features of Ambetronics Oxygen Gas Detectors

Certifications and Compliance

As a leading manufacturer of gas detectors in India, Ambetronics takes pride in its product's adherence to industrial standards.

Smart Pluggable Sensors

Exploring the necessity of these sensors in oxygen depletion alarms, highlighting their role in enhancing monitoring accuracy.

Unique Features

Delving into what Ambetronics provides that sets it apart from other gas detector suppliers, emphasizing unique features that ensure comprehensive safety.

Installation Guide: How to Install Our Oxygen Gas Detector?

Ensure a seamless integration of the GT-2511-FLP Smart Gas Detector in your industrial setting with these key steps:

1. Preliminary Assessment:

Identify gas detection hotspots and potential leak areas during a thorough site assessment.

2. Detector Placement:

Strategically position detectors in critical zones prone to oxygen deficiencies or excess.

3. Calibration Procedures:

Calibrate the detector as per the user manual before installation.

Perform regular checks to maintain accuracy, especially in variable gas concentration environments.

4. Integration with Existing Systems:

Follow guidelines for smooth integration with existing safety systems.

Utilize RS-485 Communication Port for enhanced connectivity.

5. Professional Installation:

Emphasize the necessity of professional installation by certified technicians.

Verify secure connections, aligning with safety regulations for power and communication ports.

For further inquiries or to take the next step in enhancing your industrial safety, contact Ambetronics. Visit our Contact Us page and secure your workplace with cutting-edge gas detection technology. Ensure operational continuity and peace of mind through advanced safety solutions.

Troubleshooting and Maintenance: Ensuring Reliability in Operation

Operating the GT-2511-FLP Smart Gas Detector is a straightforward process, but encountering issues is inevitable. Here’s a comprehensive guide to troubleshoot common problems and ensure the continued reliability of your Fixed Oxygen Gas Detector:

Common Issues and Troubleshooting Steps:

1. False Alarms:

– Issue: Unexpected alarms may cause disruptions.

– Troubleshoot: Review the sensor placement and environmental conditions. Ensure no interference from other gasses or environmental factors. Calibrate the detector if needed.

2. Calibration Drift:

– Issue: Gradual deviation in calibration affecting accuracy.

– Troubleshoot: Regularly calibrate the detector following the user manual guidelines. Check for environmental changes that might impact calibration stability.

3. Sensor Malfunctions:

– Issue: Malfunctioning sensors can compromise detection.

– Troubleshoot: Inspect sensors for damage or contamination. Clean or replace sensors as per the user manual. If issues persist, contact Ambetronics for professional assistance.

Contact us for Troubleshooting and Repair

Importance of Oxygen Monitoring in Industrial Settings

Regulatory Compliance and Standards before Buying any Oxygen Gas Detector.

Understanding and adhering to industry-specific regulations and standards is paramount when it comes to oxygen monitoring. Here’s a guide to ensure your Fixed Oxygen Gas Detector, specifically the GT-2511-FLP, aligns with the necessary compliance measures:

1. Industry-Specific Regulations:

– Familiarize yourself with regulations such as IS/IEC 60079-1, IS/IEC 60079-31, and IS/IEC 60079-11, which outline flameproof protection, dust ignition protection, and intrinsically safe requirements, respectively.

– Stay informed about certifications like CIMFR and PESO, ensuring your gas detector meets the specified standards.

2. Legal and Safety Implications:

– Emphasize the critical role compliance plays in ensuring legal obligations are met.

– Highlight safety implications, showcasing how adherence to standards directly contributes to the protection of personnel and assets.

– Underline the potential impact on insurance coverage, with compliant systems often qualifying for favorable terms.

3. Importance of Compliance:

– Stress the significance of compliance not just as a regulatory necessity but as a proactive safety measure.

– Showcase how adherence to standards enhances the overall safety culture within an industrial setting.

– Emphasize the potential consequences of non-compliance, including legal penalties and increased safety risks.

4. Resources for Staying Updated:

– Provide yourself with resources to stay updated on evolving standards and regulations.

– Visit the industry-specific websites, publications, or organizations that regularly publish updates.

– Attend regular training sessions to be informed about the latest compliance requirements.

Choosing the Right Fixed Oxygen Gas Detector

Selecting the optimal Fixed Oxygen Gas Detector is crucial for ensuring the safety and efficiency of your industrial operations. Here’s a step-by-step guide to help you make an informed decision tailored to your specific needs:

1. Identify Your Application:

Understand the specific application where the gas detector will be deployed.

Consider factors such as the type of industry, potential gas hazards, and the criticality of continuous monitoring.

2. Assess Environmental Conditions:

Evaluate the environmental conditions of the installation site.

Consider temperature variations, humidity levels, and potential exposure to corrosive substances.

3. Determine Budgetary Constraints:

Establish a budget for the gas detection system, factoring in the initial purchase cost, installation expenses, and potential ongoing maintenance.

4. Consider Sensor Technologies:

Evaluate different sensor technologies (Electrochemical, Catalytic, NDIR, PID, Solid State) based on their suitability for detecting specific gases and environmental conditions.

5. Explore Unique Features:

Highlight the unique selling points of the GT-2511-FLP Smart Gas Detector.

Emphasize features like the 2-Line, 4-Digit LED Display, RS-485 Communication Port, and the non-intrusive programming for Flameproof Models.

6. Ensure Compliance with Standards:

Verify that the chosen detector complies with industry-specific standards and regulations, ensuring legal and safety requirements are met.

7. Seek Professional Guidance:

Consult with industry experts or the manufacturer for personalized advice.

Leverage the expertise of Ambetronics to guide you in choosing the most suitable Fixed Oxygen Gas Detector.

Contact us for Installing Fixed Oxygen Gas Detection System

Digital Visualization of our Product: Watch our Youtube video of How Oxygen Monitoring System can make your OXYGEN monitoring at advance level.

People Also Search For:

| Oxygen Gas Leak Detector |

| O2 Gas Detector |

| O2 Leak Detector |

| Oxygen Gas Monitor |

| Oxygen Gas Detector |

| Oxygen Detector |

| Room Oxygen Monitor |

| Oxygen Meter |

| O2 Meter |

| Oxygen Depletion Alarm |

| O2 Monitoring System |

| Oxygen Detector Sensor |

| Oxygen Monitors |

| Portable Oxygen Meter |

| Confined Space Oxygen Sensor |

| Oxygen Monitoring Device |

| Oxygen Leak Detector |

| Room O2 Monitor |

| Portable Oxygen Gas Detector |

| Oxygen Gas Detector Sensor |

| Fixed Oxygen Monitor |

| O2 Gas Monitor |

| Oxygen Gas Sensor |

| Nitrogen Detector |

| Nitrogen Leak Detector |