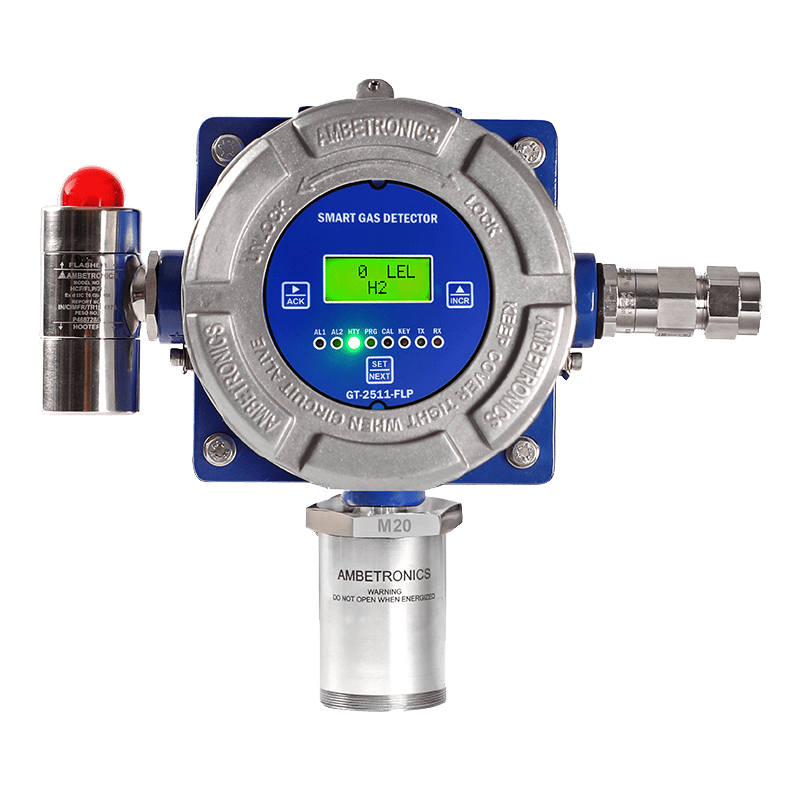

What is Hydrocarbon Gas Detector?

Hydrocarbon Gas Detectors are sophisticated instruments designed to detect even the smallest leaks of LEL Gas in industrial Area. Their primary purpose is to safeguard workers, equipment, and the environment from potential hazards.

Interested in our Hydrocarbon gas detector system?

Certifications and Compliance

The Hydrocarbon Gas Detector holds certifications for flameproof enclosures, intrinsic safety, and compliance with various standards, ensuring its reliability and adherence to safety protocols.

Understanding LEL Gas Detector

Fast and Reliable Output

These detectors provide a 4-20 mA output, ensuring immediate response to any gas leakage. The fast response time is critical in preventing accidents and minimizing the impact of gas leaks.

Smart, Pluggable Gas Sensor Modules

One standout feature is the provision for smart, pluggable gas sensor modules. These modules cover a range of gases, including Oxygen, Toxic, Combustible, PID, and NDIR sensors. This not only enhances detection capabilities but also simplifies maintenance.

Calibration and Maintenance Benefits

Calibration data, alarm data, offset data, and output current data are saved in the sensor module, facilitating easy maintenance and servicing. The detectors are highly resistant to poisoning and etching, ensuring long-term reliability.

Detection Capabilities

The Hydrocarbon Gas Detector is capable of detecting gases down to PPM, %V/V, %LEL, and mg/m3. The 2-line, 4-digit LED display and indicator lights provide a clear status of the instrument, including indications for 'Sensor Open,' 'Over Range,' 'Sensor Replace,' 'Cal Due,' 'Cal Fail,' and 'mA Loop Open.'

Applications of Hydrocarbon Gas Detectors

These detectors find applications in a wide range of industries, including refineries, cold storage, sewage plants, and more. Their versatility makes them a crucial component in various industrial processes.

Interested in our Hydrocarbon gas detector system?

General Specifications

The Hydrocarbon Gas Detector employs various sensor technologies, including electrochemical, catalytic, pellistor, NDIR, PID, and solid-state. The detection method is diffusion, and the device can detect a variety of gases.

Error Monitoring

The detectors are equipped with error monitoring capabilities, providing alerts and indications for sensor breaks, over-range situations, and output current open conditions. The clear display ensures prompt action in case of any anomalies.

Output Signals and Accuracy

The standard output includes a 4-20mA signal with configurable range and voltage selection. The calibration accuracy varies for different sensor technologies, ensuring precise detection.

Performance

With a response time of less than 15 seconds, the Hydrocarbon Gas Detector quickly reacts to the presence of gases. The electrical specifications, including supply voltage and power consumption, contribute to its efficient performance.

Environmental Considerations

Operating in a wide temperature range, from -15 to +55°C, the detector can withstand challenging environmental conditions. Its robust design makes it suitable for diverse industrial settings.

Common Deliverables and Optional Accessories

The Hydrocarbon Gas Detector comes with essential deliverables such as test calibration certificates, reference calibration gas certificates, and user manuals. Optional accessories like power supplies, mounting stands, and gas calibration kits enhance its functionality.

Optional Features of LEL Gas Detector

STEL and TWA Set Points

Optional set points for Short-Term Exposure Limit (STEL) and Time-Weighted Average (TWA) can be configured for Toxic & VOC Gases, adding an extra layer of safety.

RS-485 Communication Port

The optional RS-485 Communication Port with MODBUS RTU PROTOCOL enables seamless integration with industrial control systems.

Watch our Youtube Video of Smart Gas Detectors

FAQs

How often should the Hydrocarbon Gas Detector be calibrated?

Calibration frequency depends on usage but typically ranges from 6 to 12 months.

Can the detector be used in outdoor environments?

Yes, the detector is designed to withstand a range of environmental conditions, including outdoor settings.

What is the significance of STEL and TWA set points?

STEL and TWA set points provide additional safety measures by monitoring exposure levels over specific time periods.

Is the Hydrocarbon Gas Detector suitable for use in confined spaces?

Yes, the detector is versatile and can be used in confined spaces with proper installation.

Are there any specific industries where the Hydrocarbon Gas Detector is most commonly used?

Yes, the detector is extensively used in industries such as refineries, cold storage, sewage plants, chemical processing plants, and more.

Also Explore our other product range

People also Search

- Hydrocarbon gas detector

- LEL gas detector

- Hydrocarbon detector

- LEL detector

- LEL sensor

- Hydrocarbon leak detector

- LEL gas

Most Common Queries

- Gas Detectors

- Gas Detection System

- Gas Leak Alert System

- Peso Approved Gas Detector

- Flame Proof Gas Detector

- All types of Gas Detector

- Gas and Flame Detection System