O2 Monitoring System : Atmosphere Safety Through Gas Detection.

Ambetronics Solution for Oxygen Gas Monitoring

In the fast-paced realm of industrial operations, ensuring the safety of both personnel and assets is paramount. One critical aspect that demands meticulous attention is oxygen gas monitoring, an indispensable requirement in various sectors. This article delves into the efficacy of Ambetronics O2 Monitoring System, shedding light on its operational intricacies, unique features, and why it stands as the premier choice for industries.

GT-2511-WP

Smart Gas Detector with Weatherproof Enclosure

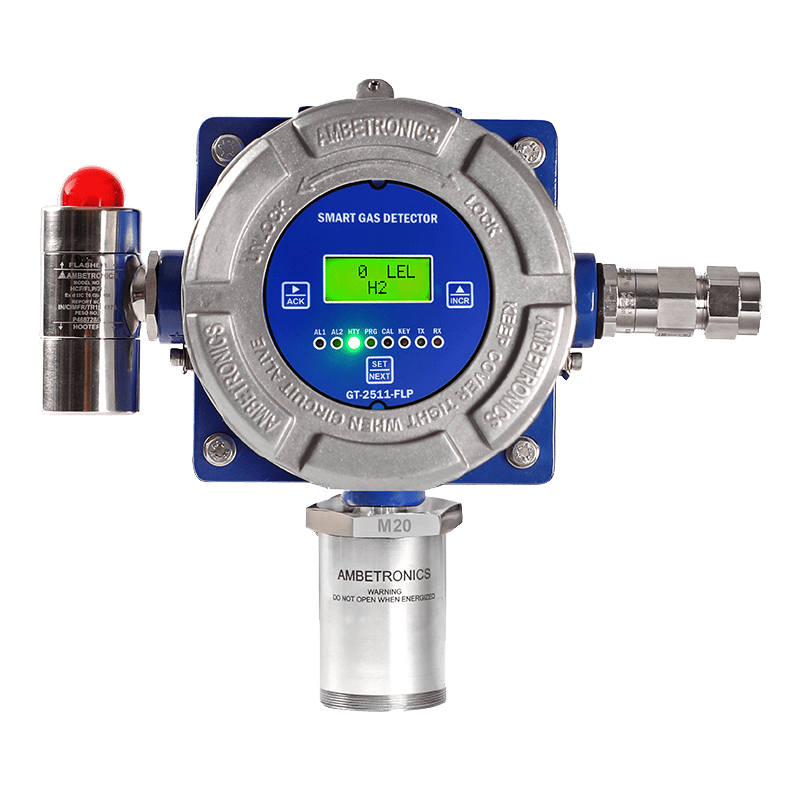

GT-2511-FLP

Smart Gas Detector with Flameproof Enclosure

PG-100-D

Portable Gas Detector

Why do we Install Oxygen Monitoring Solution?

How does the O2 Monitoring System work?

- Sensor Technology:

- Electrochemical Sensors: Commonly used in O2 monitoring systems, these sensors generate a current proportional to the amount of oxygen present. The current is then converted into an oxygen concentration reading.

- Infrared Sensors: These sensors detect the absorption of infrared light by oxygen molecules, providing a non-contact method for measuring oxygen concentration.

- Data Collection:

- The sensors continuously collect data on the oxygen levels in the monitored space.

- Signal Processing:

- The collected data is processed by the monitoring system’s electronics, which interpret the sensor signals and convert them into meaningful oxygen concentration readings.

- Display and Alarms:

- The system typically displays real-time oxygen levels on a user interface. If oxygen concentrations deviate from predefined thresholds, the system triggers alarms to alert operators or automated control systems.

- Calibration:

- O2 monitoring systems may require periodic calibration to ensure accuracy. Calibration involves comparing the sensor readings to known reference values and adjusting the system accordingly.

- Integration with Control Systems:

- In some applications, O2 monitoring systems are integrated with control systems to enable automatic adjustments to ventilation, gas supply, or other processes to maintain optimal oxygen levels.

- Data Logging and Reporting:

- Many O2 monitoring systems log data over time, allowing for historical analysis and reporting. This information can be valuable for compliance, quality assurance, or troubleshooting purposes.

- Application-Specific Features:

- O2 monitoring systems can include additional features depending on the application, such as explosion-proof housings for hazardous environments, communication interfaces for remote monitoring, or connectivity with other safety systems.

Features of Ambetronics Oxygen (O2) Monitoring System

Certifications and Compliance

As a leading manufacturer of gas detectors in India, Ambetronics takes pride in its product's adherence to industrial standards.

Smart Pluggable Sensors

Exploring the necessity of these sensors in oxygen depletion alarms, highlighting their role in enhancing monitoring accuracy.

Unique Features

Delving into what Ambetronics provides that sets it apart from other gas detector suppliers, emphasizing unique features that ensure comprehensive safety.

Monitoring Oxygen Gas in Industrial Applications - Concept and Ideas

| Refineries | Cold Storage |

| Sewage Plants | Fertilizer Plants |

| Stack Monitoring | Chlorination Plant |

| Ambient Monitoring | Gas Metering Skid |

| Gas Cylinder Bank | Oil & Gas Industries |

| Gas Pipeline Project | Pulp & Paper Plants |

| Gas Metering Station | Burner / Furnace Areas |

| Bullet Yard / Storage Yard | Chemical Processing Plant |

| Heat Treatment Plants | Chemical Storage Area |

| Control Atmosphere | Power & Industrial Plants |

Ambetronics is the Leading Manufacturer in India for Gas Detection

Datasheet - Unveiling the Features

The GT-2511-FLP sensor boasts a range of features that make it a standout solution for oxygen monitoring. With a two-line, four-digit LED display, the sensor provides real-time status updates. Calibration data, alarm data, offset data, and output current data are stored in the sensor module for easy maintenance. The sensor’s resistance to poisoning and etching, coupled with its capability to detect down to PPM, %V/V, %LEL, mg/m3, solidifies its position as a reliable choice. Download our Datasheet.

Error Monitoring - Ensuring Reliability

The system’s error monitoring capabilities add an extra layer of reliability. Whether it’s sensor break or open, over-range conditions, or output current open scenarios, the GT-2511-FLP sensor provides clear indications, allowing for swift responses and preventive measures.

Optional Accessories - Customizing Solutions

Ambetronics offers optional accessories to enhance the O2 Monitoring System’s functionality. From CE-certified power supplies to gas calibration kits and communication converters, these accessories allow industries to tailor the system to their specific needs.

In conclusion, the Ambetronics O2 Monitoring System emerges as the epitome of reliability and precision in oxygen gas detection. Its comprehensive features, compliance with industrial standards, and adaptability to various applications make it the preferred choice for industries prioritizing safety. For those seeking a robust solution to oxygen monitoring, Ambetronics stands as the go-to manufacturer, ensuring peace of mind and operational excellence.

Digital Visualization of our Product - Oxygen Gas Detector

People Also Search For:

| Oxygen Gas Leak Detector |

| O2 Gas Detector |

| O2 Leak Detector |

| Oxygen Gas Monitor |

| Oxygen Gas Detector |

| Oxygen Detector |

| Room Oxygen Monitor |

| Oxygen Meter |

| O2 Meter |

| Oxygen Depletion Alarm |

| O2 Monitoring System |

| Oxygen Detector Sensor |

| Oxygen Monitors |

| Portable Oxygen Meter |

| Confined Space Oxygen Sensor |

| Oxygen Monitoring Device |

| Oxygen Leak Detector |

| Room O2 Monitor |

| Portable Oxygen Gas Detector |

| Oxygen Gas Detector Sensor |

| Fixed Oxygen Monitor |

| O2 Gas Monitor |

| Oxygen Gas Sensor |

| Nitrogen Detector |

| Nitrogen Leak Detector |