Smart Gas Detector GT-2511-WP

Weather Proof Enclosure

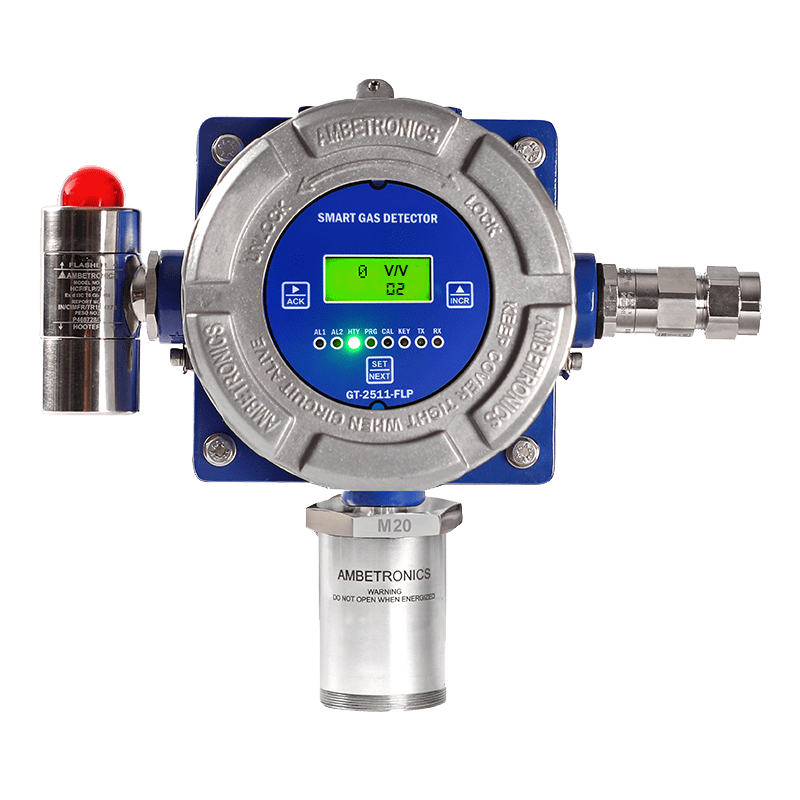

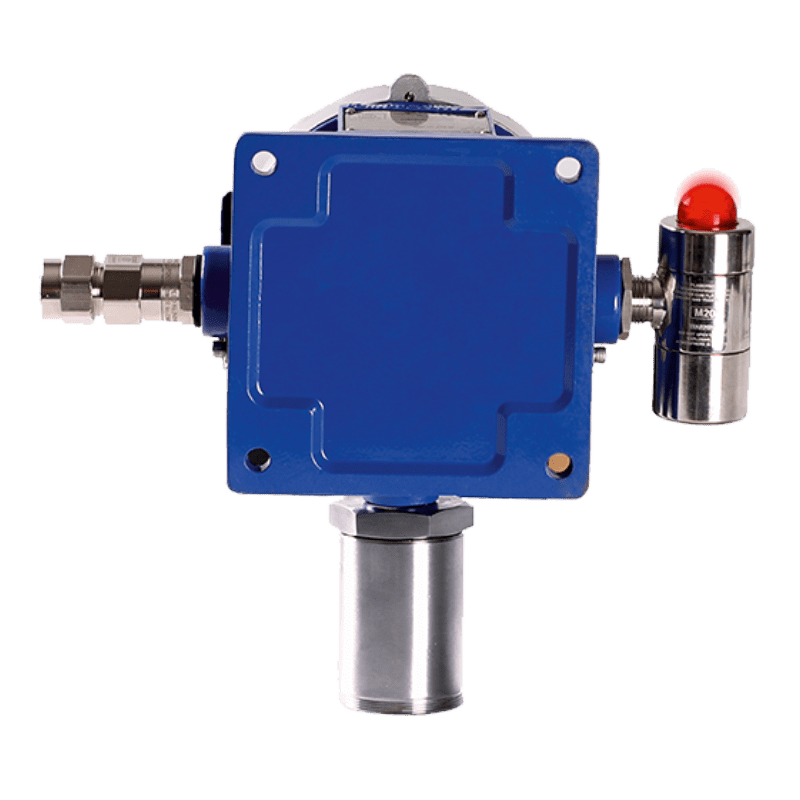

Smart Gas Detector GT-2511-FLP

Flame Proof Enclosure

Features:

- Provision for smart - Pluggable gas sensor module for Oxygen, Toxic, Combustible, PID & NDIR sensors.

- Calibration data, Alarm data, Offset data, Output current data is saved in the particular sensor module, for easy maintenance & servicing.

- Highly resistant to poisoning and etching.

- Capable of detecting down to PPM, %V/V, %LEL, PPB, mg/m3, ug/m3.

Applications:

- Refineries

- Cold Storage

- Fertilizers Plants Stack Monitoring

- Chlorination Plant

- Coal Mine and Confined Area

- Ambient Monitoring Gas Metering skid Gas Metering Station

Install Ambetronics Oxygen Gas Detector by detecting the smallest leaks of oxygen gas instantly.

Recommended By Safety Partners | Ambetronics O2 Gas Sensor for Safety!

Monitoring at all Segment

Capable of detecting oxygen gas concentrations down to PPM, %V/V, %LEL, mg/m3.

Fast Response

Ensures no threat goes unnoticed.

Real-time Information

2-line LED display and status-indicating LEDs for immediate and accurate data.

Certifications and Compliance

Our Oxygen Gas Detector adhere to stringent safety standards, boasting certifications such as Ex db IIC T6 Gb IP 66 and CIMFR/PESO certificates. Compliance with IS/IEC standards further solidifies the reliability and efficacy of our products in hazardous conditions.

Interested in our Oxygen gas detection system?

Ambetronics Oxygen Gas Detection System - Your Ultimate Oxygen Safety Companion!

Experience the power of precision with the Ambetronics Oxygen Gas Detector. Capable of detecting oxygen gas concentrations down to PPM, %V/V, %LEL, mg/m3, it ensures no threat goes unnoticed. The 2-line LED display and status-indicating LEDs provide real-time information, giving you complete control over your oxygen safety.

Innovative Safety Solutions: Ambetronics Oxygen Gas Detector Setting the Industry Standard in Oxygen Detection!

Stay ahead with optional features like RS-485 Communication Port with MODBUS RTU PROTOCOL and non-intrusive programming. Password protection and alarm acknowledgment make it an industry standard for oxygen safety innovation.

Why choose Ambetronics Oxygen Gas Detector?

When it comes to ensuring the safety of your industrial workspace, choosing the right Oxygen Gas Detector is paramount. Ambetronics stands out as a reliable and innovative provider in this field. Here are compelling reasons why Ambetronics should be your top choice:

Cutting-Edge

Technology

Ambetronics employs cutting-edge technology in its Oxygen Gas Detectors, ensuring accurate and timely detection of oxygen levels. The use of advanced sensors and detection mechanisms sets Ambetronics apart in providing a reliable solution for workplace safety.

Customized

Solutions

Ambetronics understands that each industrial setting is unique. Therefore, their Oxygen Gas Detectors and Gas Monitoring Systems are customizable to suit the specific needs of your facility. Whether it’s configuring with exhaust fans or integrating with control valves, Ambetronics offers tailored solutions for your safety requirements.

Proven Track

Record

With a proven track record in delivering high-quality safety solutions, Ambetronics has gained the trust of industries worldwide. Their commitment to excellence and customer satisfaction makes them a leader in the field of gas leak detection.

Installation of Ambetronics Oxygen Gas Detection System:

1. Location of Detector:

- It’s recommended to install O2 monitoring system inside each working area (where N2 is used) with an inbuilt Hooter-cum-Flasher.

- The gas detector should be installed near the source of the leakage and at height of 4-6 feet above floor level.

- All the gas detectors will be integrated to a multi-channel Gas monitor which is installed in the security officer’s cabin.

- The detector will be addressable type if new detectors are to be installed.

- We also suggest to install one alarm in corridor, & finally an alarm in the security officer’s cabin

2. Alarm Activation Settings

To ensure the safety of the personal in the critical area, it’s recommended to set the Alarm levels as:- Alarm 1: 19.5% V/V

- Alarm 2: 18.5% V/V

3. Main Panel at Security Cabin:

- Main panel will be connected with each local panel via LAN network and will show gas value of all Oxygen detectors in plant and generate alarm in case of oxygen deficiency.

- Main panel consist of PLC cum HMI, HMI with 12 inch or more display size with 1 month Data logging facility and direct printing option.

- Main control panel will send SMS alerts to concern person in case of alarms.

How to Calibrate the Existing Oxygen Gas Detector?

Ensuring the accuracy of your existing Oxygen Gas Detector is crucial for maintaining a safe working environment. Follow these steps to calibrate your detector:

Step 1:

Assessment

Begin by assessing the current calibration status of your Oxygen Gas Detector. Identify any deviations from the recommended calibration levels.

Step 2:

Calibration Process

Follow the calibration guidelines provided by Ambetronics to fine-tune your existing Oxygen Gas Detector. This process ensures accurate readings and reliable performance.Step 3:

Verification

After calibration, conduct a verification process to confirm the accuracy of your Oxygen Gas Detector. This step is essential for maintaining the effectiveness of the detection system.

By choosing Ambetronics and following these installation and calibration guidelines, you’re taking proactive measures to enhance safety in your industrial workspace.

Types of Oxygen Monitoring Solution given by us:

| Type of Detector | Type of Area in Which to Install |

| Weatherproof Detector | Safe Area |

| Flameproof Detector | Flammable / Hazardous Area |

| Flush Type Detector | Cleanroom Safe Area |

| Flameproof with Stainless Steel Enclosure | Safe Area |