Oxygen Monitoring Device Providing Unparalleled Safety in Industrial Spaces

Introduction

GT-2511-WP

Smart Gas Detector with Weatherproof Enclosure

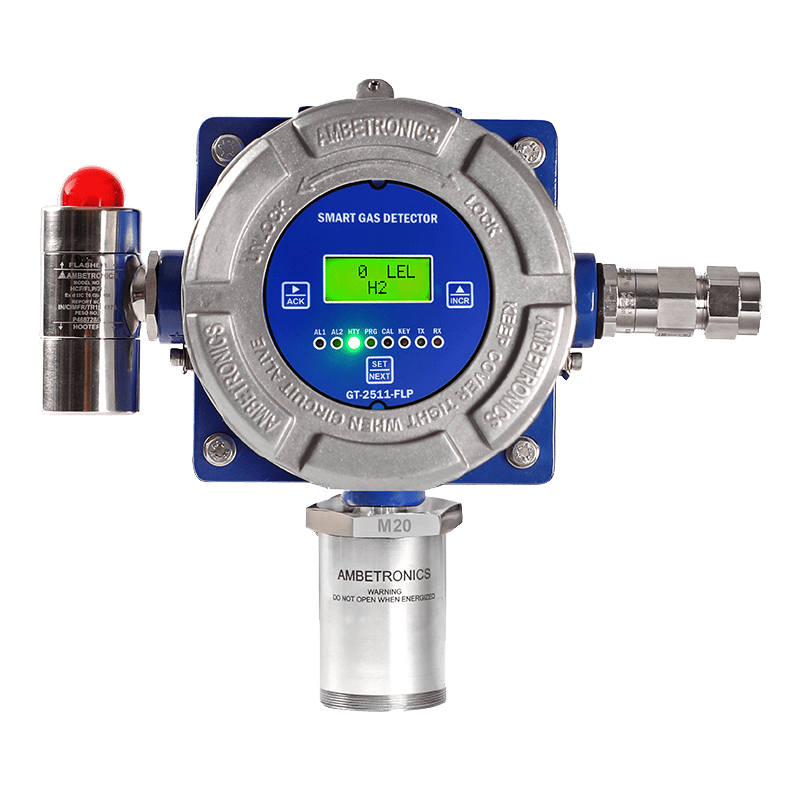

GT-2511-FLP

Smart Gas Detector with Flameproof Enclosure

PG-100-D

Portable Gas Detector

Impact of Oxygen Monitoring Device in Industrial Areas

Highlighting Potential Risks without our Oxygen Monitoring Device

Features of Ambetronics Oxygen Gas Detectors

Certifications and Compliance

As a leading manufacturer of gas detectors in India, Ambetronics takes pride in its product's adherence to industrial standards.

Smart Pluggable Sensors

Exploring the necessity of these sensors in oxygen depletion alarms, highlighting their role in enhancing monitoring accuracy.

Unique Features

Delving into what Ambetronics provides that sets it apart from other gas detector suppliers, emphasizing unique features that ensure comprehensive safety.

Explore Ambetronics Oxygen Monitoring Device with All Functionality a Safety Manager Needs in His Industry

Ambetronics presents a range of Oxygen Monitoring Systems tailored to meet the diverse needs of safety managers. Let’s delve into the functionalities and features that make these devices indispensable in industrial settings.

Explore the Applications of O2 Gas Detector

| Refineries | Cold Storage |

| Sewage Plants | Fertilizer Plants |

| Stack Monitoring | Chlorination Plant |

| Ambient Monitoring | Gas Metering Skid |

| Gas Cylinder Bank | Oil & Gas Industries |

| Gas Pipeline Project | Pulp & Paper Plants |

| Gas Metering Station | Burner / Furnace Areas |

| Bullet Yard / Storage Yard | Chemical Processing Plant |

| Heat Treatment Plants | Chemical Storage Area |

| Control Atmosphere | Power & Industrial Plants |

Importance of Oxygen Monitoring in Industrial Settings

Specific Challenges and Hazards Regarding Low-Level Monitoring System

How Machinery Operation in Confined Spaces Impacts Oxygen Levels

Machinery operation within confined spaces restricts the natural dispersion of oxygen, leading to potential fluctuations in oxygen levels. Processes such as combustion, chemical reactions, and the utilization of equipment contribute to these variations.

Our Oxygen Monitoring Device: A Proactive Solution

In essence, the Oxygen Monitoring Device becomes a critical ally in mitigating risks associated with machinery operation in confined spaces, guaranteeing that oxygen levels align with safety standards at all times.

Features of Ambetronics Oxygen Monitoring Device

Flameproof Enclosure - GT-2511-FLP

1. Rugged Design: Withstands harsh industrial conditions.

2. Certifications: Ex db IIC T6 Gb IP66 ensures compliance with stringent safety standards.

3. Non-Intrusive Programming: Facilitated using a magnetic wand for added safety.

4. Alarm Acknowledgement: Allows acknowledgment of alarms from both front and rear terminals.

Weatherproof Enclosure - GT-2511-WP

1. Versatile Deployment: Suitable for a range of environmental conditions.

2. Certifications: Complies with IS/IEC standards for weatherproof protection.

3. Remote Monitoring: Enables monitoring in challenging outdoor settings.

4. Quick Installation: Streamlined setup for efficiency.

Portable Gas Detector - PG-100

1. Portability: Ideal for on-the-go monitoring in various locations.

2. Real-time Readings: Provides instant and accurate oxygen level readings.

3. Battery Operated: Ensures uninterrupted monitoring without external power.

4. Visual Indicators: LED display and status indicators for enhanced user interaction.

Benefits of Regular Monitoring

1. Early Detection: Identifies Oxygen leaks before they escalate.

2. Prevention of Hazardous Situations: Proactively mitigates risks in real-time.

3. Increased Safety:Safeguards personnel and equipment from potential dangers.

4. Compliance: Ensures adherence to safety regulations for industrial standards.

How to Install the Oxygen Monitoring System

1. Select an Appropriate Location

Choosing the right location is fundamental to the device's performance. Consider the following factors:

Proximity to Potential Leak Sources: Install the device in areas where the likelihood of oxygen leaks is highest.

Accessibility: Ensure easy access for maintenance without compromising safety.

Strategic Placement

2. Ensure Proper Power Supply

A stable and reliable power supply is essential for uninterrupted monitoring. Take these steps to ensure proper power:

Voltage Compatibility: Confirm that the power supply voltage aligns with the device's specifications.

Backup Power: Consider installing a backup power source to prevent downtime during power outages.

Constant Monitoring: Regularly check the power status to guarantee continuous operation.

3. Connect the Device as Per the Provided Manual

Follow the step-by-step instructions outlined in the provided manual for a correct and secure connection:

Cable Connections:Use appropriate cables and connectors as specified in the manual.

Sensor Integration: If applicable, ensure the gas sensor is correctly integrated into the system.

Data Cable Placement: Lay data cables away from power cables to prevent interference.

Constant Monitoring: Regularly check the power status to guarantee continuous operation.

4. Verify Connections for Accuracy

Thoroughly check and verify all connections to guarantee accuracy and reliability:

Visual Inspection:Conduct a visual inspection of all connections to identify any loose or damaged components.

Functional Testing: Perform a functional test to ensure the device responds accurately to simulated situations.

Calibration Check: Confirm that the device is calibrated according to the recommended schedule.

By diligently following these installation steps, safety managers can establish a robust foundation for the Oxygen Monitoring System, enhancing workplace safety and ensuring optimal device performance.

Importance of Oxygen Monitoring in Industrial Settings

Digital Visualization of our Product: Watch our Youtube video of How Oxygen Monitoring System can make your monitoring at advance level.

People Also Search For:

| Oxygen Gas Leak Detector |

| O2 Gas Detector |

| O2 Leak Detector |

| Oxygen Gas Monitor |

| Oxygen Gas Detector |

| Oxygen Detector |

| Room Oxygen Monitor |

| Oxygen Meter |

| O2 Meter |

| Oxygen Depletion Alarm |

| O2 Monitoring System |

| Oxygen Detector Sensor |

| Oxygen Monitors |

| Portable Oxygen Meter |

| Confined Space Oxygen Sensor |

| Oxygen Monitoring Device |

| Oxygen Leak Detector |

| Room O2 Monitor |

| Portable Oxygen Gas Detector |

| Oxygen Gas Detector Sensor |

| Fixed Oxygen Monitor |

| O2 Gas Monitor |

| Oxygen Gas Sensor |

| Nitrogen Detector |

| Nitrogen Leak Detector |