Safety Solution in Pharmaceutical Plants

Fire and Gas Detection in Pharma Plants

Introduction: In the pharmaceutical industry, ensuring the safety and integrity of operations is of utmost importance. This means not only protecting the well-being of employees but also the surrounding area where there is high chances of Fire or Toxic gas leakage. Ambetronics introduce you All in One Solution for Gas Detection and Flame detection in Pharmaceutical Plants.

We Detect Toxic, Combustible, Oxygen, VOC, Hydrocarbon gasses as well as Flames too.

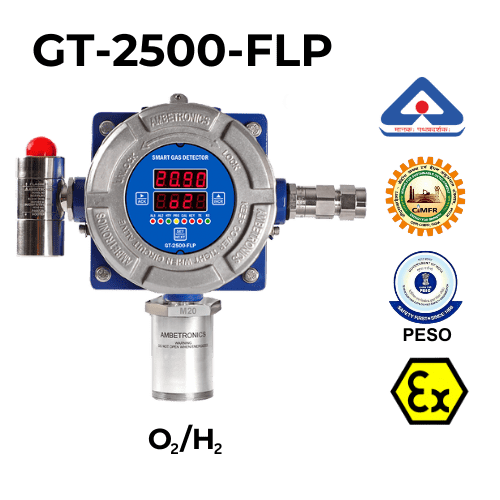

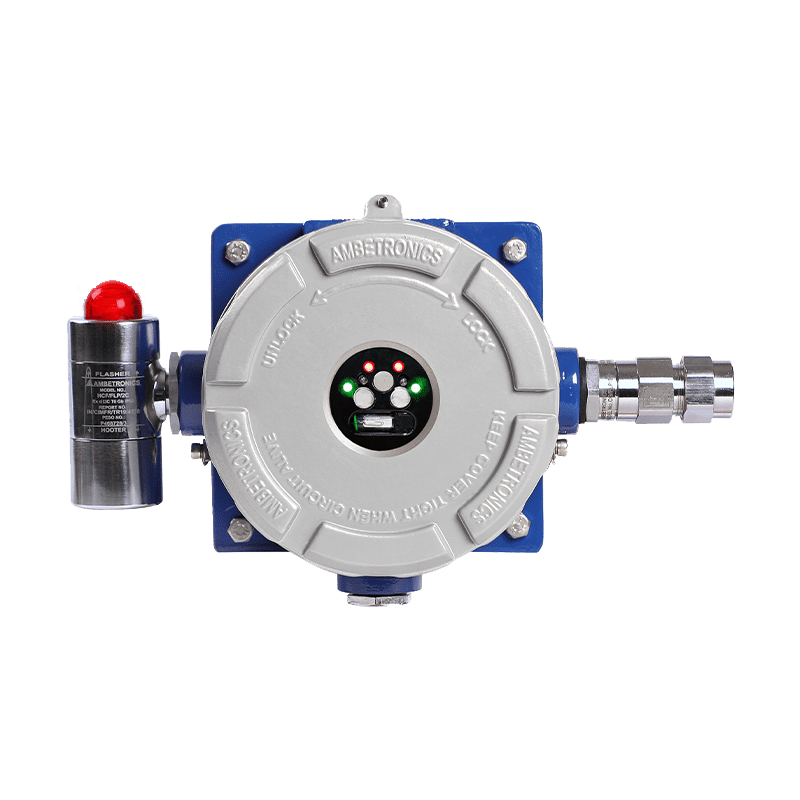

In the GC Room/ Pharma Lab Area, The Oxygen Gas and Hydrogen Gas Detector is essential for maintaining a safe working environment. These detectors monitor oxygen and hydrogen levels, preventing potential fire hazards or explosions. By installing the GT-2500-FLP, pharmaceutical plants can proactively ensure safety standards are upheld, safeguarding both personnel and valuable assets.

Oxygen and Hydrogen Gas Detector

- Fast and Reliable Output: Detects the smallest leak of toxic and combustible gases.

- Enclosure: IP66/IP68 protection class for durability.

- Hot Swappable Smart Sensor: Allows on-site replacement if required.

- Automatic Calibration: Alerts for easy maintenance.

- Non-Intrusive Programming: Simplifies setup using a magnetic wand.

- RS-485 Communication Port: Optional communication protocol for compatibility.

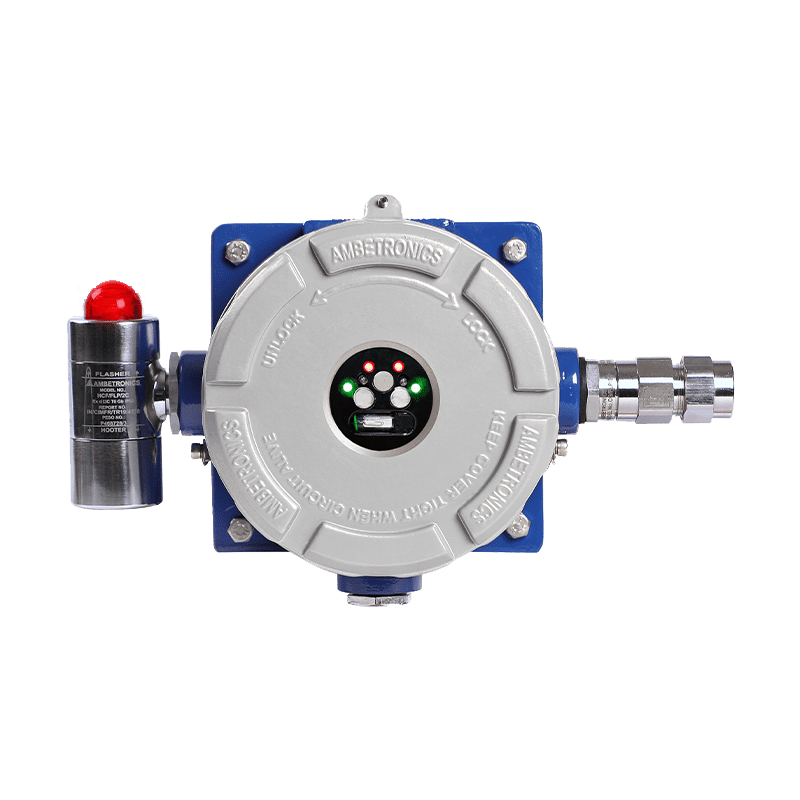

In the Centrifuge/Reactor Rooms our Gas Detector ensures a safe environment by detecting Oxygen and Hydrocarbon Gas. Alongside, the Online Oxygen Gas Analyzer methodically monitors gas levels, including smallest leak of oxygen, preventing potential hazards. Incorporating these instruments maintains stringent safety standards, safeguarding personnel and assets effectively.

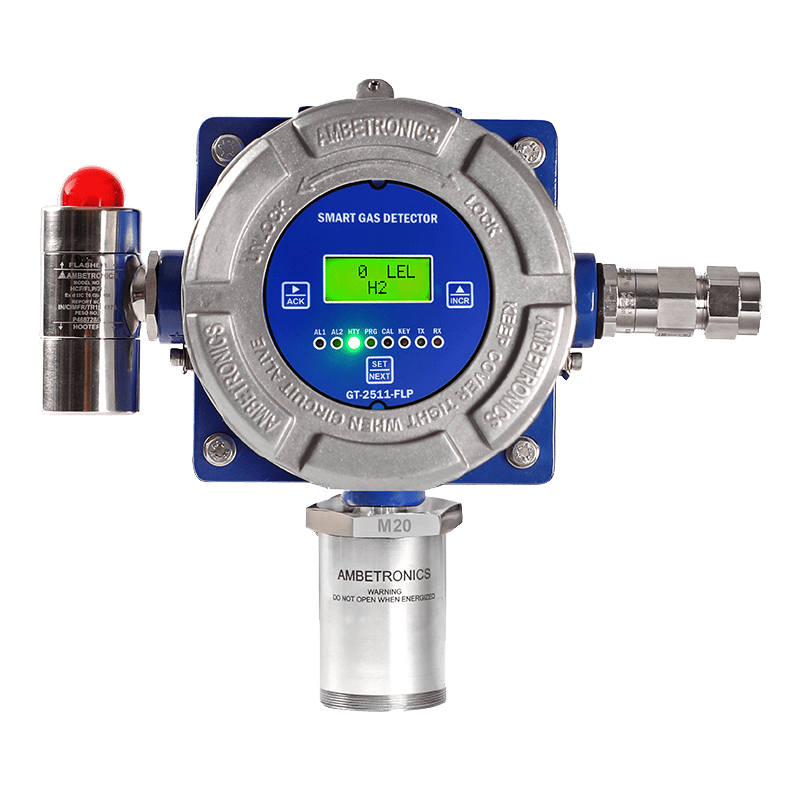

Oxygen and Hydrocarbon Gas Detector

- Provides a fast reliable output for detection a smallest leak of Oxygen,

Toxic, Combustible and Volatile Organic Compounds (VOC). - Provision for smart – Pluggable gas sensor module for Oxygen, Toxic,

Combustible, PID & NDIR sensors. - Calibration data, Alarm data, Offset data, Output current data is saved in

the particular sensor module, for easy maintenance & servicing. - Highly resistant to poisoning and etching.

- Capable of detecting down to PPM, %V/V, %LEL, mg/m3.

- 2-Line, 4-Digit 8 mm (H) Seven Segment LED Display & 8 LEDs to indicate

status of instrument

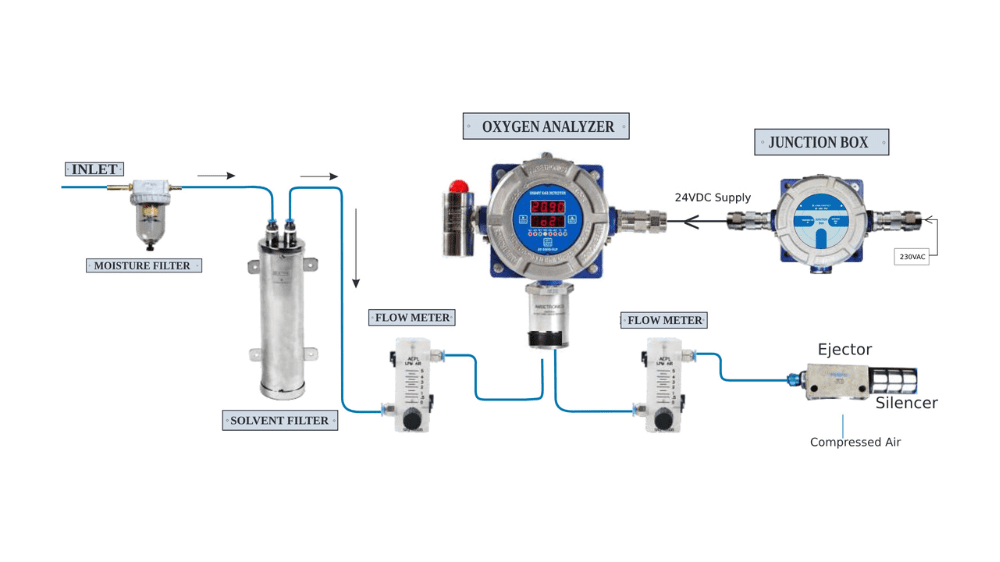

Illustration of Ambetronics Online Oxygen Gas Analyzer with Sampling System in Pharmaceutical Plant

Gas Analyzer for measure Nitrogen Purity

- Optimized for detection of smallest leak of Oxygen.

- Intrinsically safe device with an IP66 FLP Housing

- Certified for use in hazardous areas when powered by

an intrinsically safe barrier - Operates with chemically resistant range of oxygen sensors.

- Long life and high reliability

- Chemical resistance Oxygen Sensor

- Unaffected by most background Solvent Gases

- Digital display of O % Concentration on LED Display 2

- Analogue 4-20mA output for retransmission of measured signal

- Remote Mounted / Direct Mounted Oxygen Sensor for ease of use

and maintenance - Password protected programming with password changing facility.

- Optional Alarm relay contacts with two configurable Alarm levels &

one Relay for fail safe relay. - Optional RS-485 communication port with MODBUS RTU Protocol

GA 3500-PM

Smart Gas Analyzer for Oxygen

In Pharmaceutical Plant Server Rooms, our comprehensive monitoring solutions ensure optimal safety. We provide essential instruments such as O2 sensors, SOX/NOX sensors, and temperature and humidity transmitters. These devices work together to monitor critical parameters, ensuring a controlled environment conducive to sensitive equipment operation. By incorporating our monitoring solutions, pharmaceutical plants can maintain stability and reliability in their server rooms, safeguarding data integrity and operational efficiency.

O2 and SOX/NOX Sensor:

- Provides a fast reliable output for detection a smallest leak of Toxic and Combustible Gases emitted

in Battery Rooms. - Enclosure: Protection Class: IP65

- Hot Swappable Smart sensor with Calibration memory Inside Sensor.

- Sensor can be replace on site immediately if require.

- Common inventory for all different type Gas Detector so reduces spares cost.

- for Projects Smart sensor can be supplied at the time of execution of Project so to prevent life of

sensor during idle period. - Highly resistant to poisoning and etching due to special coating

- Automatic Calibration due alert for easy maintenance

- Non-Intrusive programming for using Magnetic Wand.

- Password protected programming with changing facility.

- Reverse Polarity Protection

- Standard 4-20mA signal output with configurable range.

- Standard 0-10V/0-5V/ 0-1V signal output with configurable range.

- Optional RS-485 Communication Port with MODBUS RTU PROTOCOL.

- 2 KV Isolated RS-485 Modbus Communication RTU

- Non-Intrusive programming for Flameproof Model using front push button.

- Password protected programming with Password Changing Facility.

- Alarm Acknowledgment Facility from front as well as rear terminal.

- ‘Test Mode’ provided to check the electronics as Alarm LEDs, Relays, Output current/voltage with

or without sensor module. - Optional Alarm Relay contacts on board with two configurable Alarm Levels & One Fail Safe Relay.

- Output compatible to any make Fire Alarm Panel.

GT-2500-WP

O2 Sensor

GT-2511-WP

SOX/NOX Sensor

Temperature and Humidity Transmitter:

- Temperature range is -20 to 60ºC with accuracy of ± 0.5 ºC.

- Relative Humidity range is 0 to 100%RH with accuracy of ± 2%RH.

- Standard 4-20mA signal outputs with configurable range.

- Optional Isolated RS-485 communication port with MODBUS RTU Protocol.

- Software calibration for both Temperature & Relative Humidity

TRH-554-WP

Temperature and Humidity Transmitter

In the Solvent Storage Area of pharmaceutical plants, the presence of volatile organic compounds (VOCs) and hydrocarbon gasses poses potential risks. To mitigate these hazards, the installation of the GT-2511-FLP Gas Detector is essential. This advanced detector accurately monitors VOC and hydrocarbon gas levels, providing early detection of any leaks or abnormalities. For any chances of fire emission, FLD-3311-FLP installation becomes mandatory.

VOC and PID Gas Detector:

- Provides a fast reliable output for detection a smallest leak of Oxygen, Toxic, Combustible and Volatile Organic Compounds (VOC).

- Provision for smart – Pluggable gas sensor module for Oxygen, Toxic, Combustible, PID & NDIR sensors.

- Calibration data, Alarm data, Offset data, Output current data is saved in the particular sensor module, for easy maintenance & servicing.

- Highly resistant to poisoning and etching.

- Capable of detecting down to PPM, %V/V, %LEL, mg/m3.

- 2-Line, 4-Digit 8 mm (H) Seven Segment LED Display & 8 LEDs to indicate status of instrument

- Indication for ‘Sensor Open’, ‘Over Range’, ‘Sensor Replace’, ‘Cal Due’, ‘Cal Fail’, mA Loop Open.

- Standard 4-20mA signal output with configurable range.

- Optional STEL and TWA set points can be configured for Toxic & VOC Gases.

GT-2511-FLP

Smart Gas Detector

Flame Detector:

- Detector detects Multi-Spectral Sensitivity of fire by using UV & IR sensors

- Clear Line of Sight visual range (upto specific distance)

- Triple Spectrum Design- For long distance detection & Excellent false alarm immunity

- Sensitivity Selection – To ensure no zone cross over detection.

- High sensitivity combined with fast response time to ensure rapid & accurate flame detection.

- Multiple output options for maximum flexibility and compatibility.

FLD-3311-FLP

Single UV and Triple IR Sensor Flame Detector

In the tank farm area and warehouse hazardous area of pharmaceutical plants, the presence of potential fire hazards demands vigilant monitoring. With the FLD-3311-FLP Triple IR and UV Flame Detector, pharmaceutical plants can enhance their safety measures significantly. This advanced detector utilizes cutting-edge technology to detect fires swiftly and accurately, providing early warning and preventing potential disasters. By incorporating the FLD-3311-FLP into these critical areas, pharmaceutical plants can effectively mitigate fire risks, safeguarding personnel, assets, and operations.

Flame Detector:

- Detector detects Multi-Spectral Sensitivity of fire by using UV & IR sensors

- Clear Line of Sight visual range (upto specific distance)

- Triple Spectrum Design- For long distance detection & Excellent false alarm immunity

- Sensitivity Selection – To ensure no zone cross over detection.

- High sensitivity combined with fast response time to ensure rapid & accurate flame detection.

- Multiple output options for maximum flexibility and compatibility.

FLD-3311-FLP

Single UV and Triple IR Sensor Flame Detector

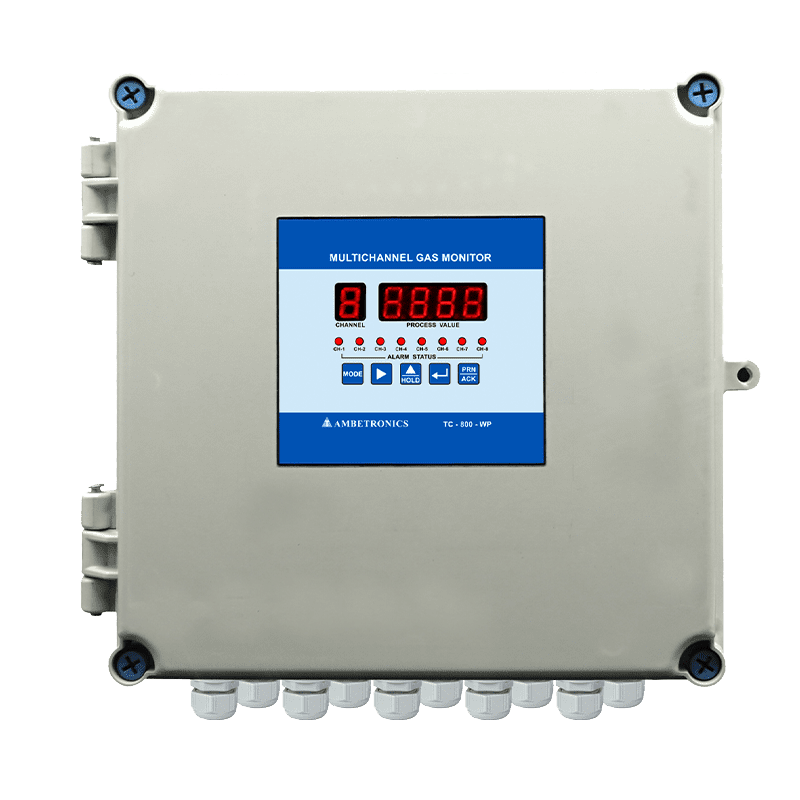

In the warehouse safe area of pharmaceutical plants, maintaining optimal environmental conditions is crucial for preserving product integrity and safety. With the TRH-554 Series Temperature and RH Transmitter and TC-800-WP Data Logger, pharmaceutical plants can ensure precise monitoring of temperature and humidity levels. These advanced instruments offer real-time data logging and accurate measurements, enabling proactive management of environmental parameters. By incorporating the TRH-554 Series and TC-800-WP into their warehouse safe areas, pharmaceutical plants can uphold stringent quality standards, safeguarding product quality and compliance

Temperature and RH Transmitter:

- Highly accurate Digital technology sensor gives fast and reliable output.

- Temperature range is -40°C to +100°C with accuracy of ± 0.5 ºC.

- Relative Humidity range is 0% RH to 100%RH with accuracy of ± 2%RH.

- Long term stable output for both Temperature and Relative Humidity.

- Digital Display of Temperature & Relative Humidity on Seven Segment Display

- Standard 4-20mA signal outputs with configurable range.

- Easy handling & programming with 3 keys

- Password protected programming with password changing facility.

- Software calibration for both Temperature & Relative Humidity.

- Flash Memory for Data security in the event of power failure.

- Optional 2 Nos. Alarm relay contacts with two configurable Alarm levels & one relay for fail safe relay.

- Optional Isolated RS-485 communication port with MODBUS RTU Protocol.

- Compact size, can be easily installed.

TRH-554-FLP

Temp and RH Transmitter

TRH-554-WP

Temp and RH Transmitter - Weatherproof Enclosure

Data Logger:

- Used latest micro controller based technology for better accuracy

- 8 Channel fixed input for all type of thermocouple ( J, K, R, S, T, E, B, N) programmable by user, RTD (PT-100), 4-20mA & 0-10 VDC factory settable

- Easy on-line field calibration by front panel membrane keypad

- Field programmable channel scan time 1 to 59 sec., Logging interval

1 to 9999 sec & Printing Interval 5 to 9999 sec. - Optional RS-485 Modbus Serial Port

- Optional Parallel Printing Port

- Automatic cold junction compensation for Thermocouples

- Temp. reading in °C & °F by user selectable

TC-800-WP

Data Logger

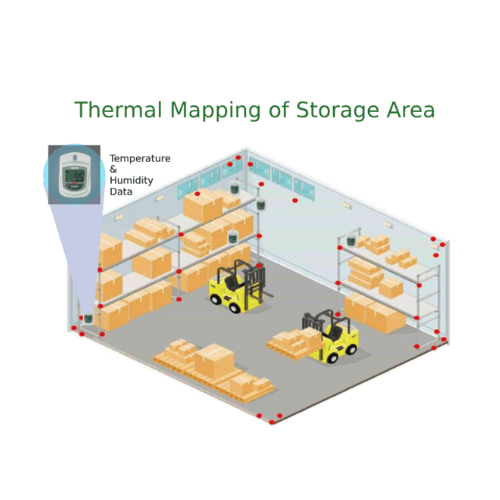

Services Offered for Thermal Mapping of Storage Area:

- Computer System Validation (CSV) complying

regulatory requirements of good automated

machine practice (GAMPS) USFDA

21CFR Part 11 - Thermal / RH Validation Complying regulatory

requirements of WHO (World Health Organisation) - System Qualification

- Annual Maintenance Contract (AMC)/

Comprehensive Maintenance Contract (CMC) - Calibration Services (On-site / In-house)

With the integration of essential monitoring devices such as oxygen monitoring sensors, temperature/RH/DP monitors, and smart gas transmitters, pharmaceutical plants can uphold stringent cleanliness standards effectively. These advanced instruments enable real-time monitoring and control of critical parameters, ensuring a clean and safe environment for pharmaceutical production. By incorporating these devices into their clean room areas, pharmaceutical plants can enhance operational efficiency and product quality while meeting regulatory requirements with confidence.

Oxygen Monitor:

- 4 digit Seven Segment 0.4″ Red L.E.D. display for Oxygen gas indication in % V/V

- Range : 0 to 25 %V/V

- User Programmable Alarms AL1, AL2.

- Isolated RS-485 with Modbus RTU

- 1 No. SPDT relay for rating “2A/120VAC, 2A/24VDC

CRM-111-2

Remote Oxygen Sensor

Smart Gas Transmitter:

- Provides a fast reliable output for detection a smallest leak of Oxygen, Toxic, Combustible

- Provision for smart – Pluggable gas sensor module

- Calibration data, Alarm data, Offset data, Output current data is saved in the particular sensor module, for easy maintenance & servicing.

- Highly resistant to poisoning and etching.

- Capable of detecting down to PPM, %V/V, %LEL, mg/m3.

- 2-Line, 4-Digit 8 mm (H) Seven Segment LED Display & 8 LEDs to indicate status of instrument

- Indication for ‘Sensor Open’, ‘Over Range’, ‘Sensor Replace’, ‘Cal Due’, ‘Cal Fail’, mA Loop Open.

- Standard 4-20mA signal output with configurable range.

- Optional STEL and TWA set points can be configured for Toxic & VOC Gases.

- Optional RS-485 Communication Port with MODBUS RTU PROTOCOL.

- Non – Intrusive programming for Flameproof Model using Magnetic Wand.

- Password protected programming with Password Changing Facility.

- Alarm Acknowledgement Facility from front as well as rare terminal.

- ‘Test Mode’ provided to check the electronics as Alarm LEDs, Relays, Output current / voltage with or without sensor module.

- Optional Alarm Relay contacts on board with two configurable Alarm Levels & One Fail Safe Relay.

GT-2500-FLP-SS-HCF

Smart Gas Transmitter

The IoT gateway in a pharmaceutical plant serves as a crucial link between the various sensors, devices, and systems within the facility. It collects, processes, and transmits data from equipment such as temperature sensors, humidity monitors, and pressure gauges to a central management system. This enables real-time monitoring and control of critical parameters, ensuring compliance with regulatory standards, enhancing efficiency, and facilitating timely responses to any deviations or issues. Additionally, the IoT gateway can facilitate predictive maintenance, helping to prevent equipment failures and minimize downtime, ultimately contributing to the overall reliability and productivity of the pharmaceutical manufacturing process.

IoT Gateway with Call Alert, Mail Alert and SMS Alert

- The IoT data logger supports 32 channels/process values with signed and bitwise data types.

- Connectivity options include GSM/GPRS with two SIM card slots, but WiFi and LoRa are not supported.

- It features RS-485 MODBUS RTU input/output and optional MODBUS TCP output.

- Alarm notifications include voice calls, SMS, and emails with scheduled reports available.

- Data logging intervals range from 1 to 60 minutes with a capacity of 50,000 data records and 15,000 event logs using MQTT (JSON) communication protocol.

- Fail-safe memory and a buzzer are integrated with a supply voltage of 9V to 24V/3 Amp DC.

- Optional features include GPS, additional MODBUS TCP output, and up to 2 settable alarms per channel.

- Environmental specifications range from -10°C to 50°C operating temperature, -20°C to 60°C storage temperature, and humidity less than 95% non-condensing.

- The housing is made of ABS plastic, with dimensions of 150 (W) x 90 (H) x 55 (D) mm, weighing approximately 270 grams, and designed for wall mounting.