Our Standard Certifications

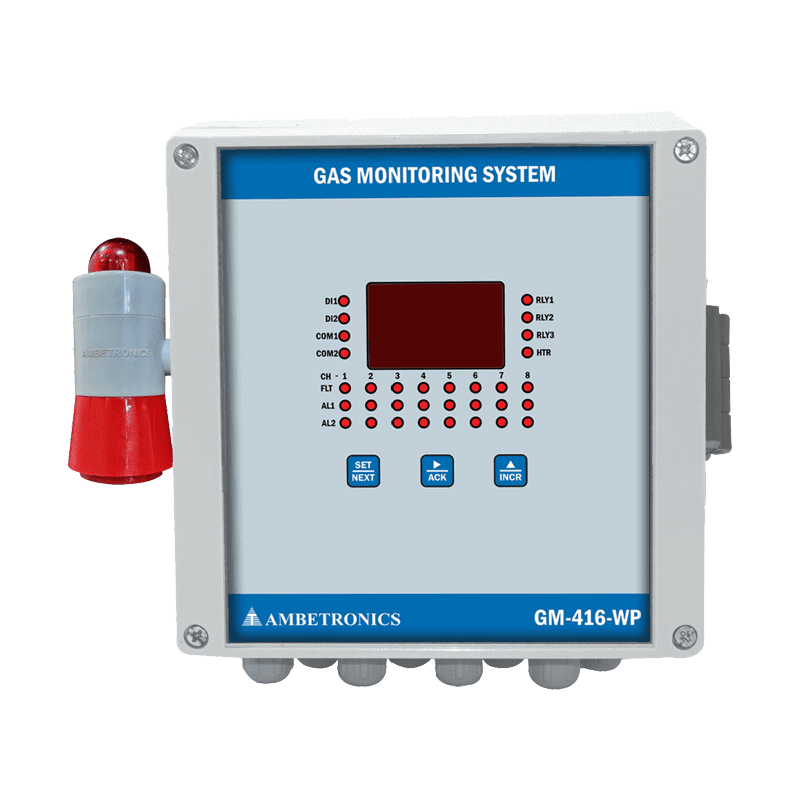

Gas Monitoring System GM-416-WP

The GM-416-WP Gas Monitor is an advanced gas monitor designed for various applications, including bullet yards, gas cylinder storage, building management services, and more. It features a robust MODBUS ID monitoring system with RS-485 MODBUS RTU network connectivity, supporting 8, 16, or 24 detectors. The system employs a ring topology for redundancy, ensuring continuous operation even in the event of wire breaks. With a multidrop RS-485 port, the need for separate cabling to each detector is eliminated, simplifying installation. The system includes a user-friendly interface with a 2 x 4 digit LED display and 32 LEDs for clear status indication. It scans all channels within a programmable time frame, offering flexibility in monitoring.

1. Versatile Channel Configurations: Gas Monitor supports 8, 16, and 24 channel configurations for flexible gas detection in various industrial settings.

2. MODBUS RTU Network Connectivity: Gas Monitor utilizes RS-485 MODBUS RTU network connectivity on 4-wire technology for efficient and reliable communication.

3. Redundancy with Ring Topology: Offers ring topology for redundancy, ensuring continuous system operation even in the event of wire breaks.

4. Multidrop RS-485 Port: Eliminates the need for separate cabling to each detector with a multidrop RS-485 port, simplifying installation.

5. Programmable Display Scan: Features a programmable display scan time (1 to 999 seconds) to monitor all channels effectively.

6. Digital Inputs: Includes 2 digital inputs for additional input signals or external device integration.

7. LED Display and Status Indicators: Equipped with 2 x 4 digit LED display and 32 LEDs for clear status indication of alarms, faults, and communication status.

8. Integrated Buzzer and Relays: Integrated buzzer and 3 SPDT relays provide audible and visual warnings for alarm set point violations.

9. Password-Protected Menu: Ensures security with a password-protected menu and the ability to change passwords.

10. User-Friendly Programming: Easy handling and programming with 3 keys on the front panel.

Technical Specifications:

1. Input: Supports 8, 16, 24 detectors with RS-485 MODBUS RTU port.

2. Control Action: 3 independent relays common for all channels, operating based on slave status.

3. Audible Indication: Integrated buzzer and hooter for alarm set point violation.

4. Range & Resolution: Offers three resolution options – 0, 0.1, and 0.01.

5. Environmental Conditions:

– Operating Temperature: 0 to 50°C.

– Humidity: Less than 95% RH non-condensing.

6. Electrical:

– Supply Voltage: 90 to 270 VAC, typically 230 VAC.

– Current for Slave Device: Less than 1.5 Amp at 24VDC for 8 channels; junction box with SMPS required for 16 & 24 channels.

7. Communication:

– Communication Port: Isolated RS-485 communication with MODBUS RTU protocol.

– Settings: Baud rate (9.6, 19.2), Parity (O/E/N), Stop bits (1/2), Number of Slave IDs (1-250).

8. Error Monitoring:

– ERR indication for OPEN/OVER range of slave devices.

– BREK indication for cable breaks, read errors, or improper communication settings.

9. Relay:

– 3 Nos. SPDT Relay with rating for NO CONTACT (10A 250VAC/5A 30VDC) and NC CONTACT (3A 125VAC/3A 30VDC).

– Relay 1 for Alarm 1, Relay 2 for Alarm 2, and Relay 3 for Fault.

10. Programmable Parameters:

– Set Point: 2 Nos. AL1, AL2 user-settable in the device and configurable through Modbus Protocol.

– Settings: 3 keys on the front panel with password protection.

– Logic: LOW-LOW, HIGH-HIGH, LOW-HIGH user-settable.

11. Weatherproof Housing:

– Cabinet Material: ABS Plastic.

– Cable Entry: PG 12 cable gland.

– Mounting: Wall Mounting.

– Dimensions: 182 mm (H) x 214 mm (W) x 81.5 mm (D).

– Weight: Approx. 950 g.

12. Accessories:

– Weatherproof enclosure for interconnection between detector and multichannel communicator.

– 24VDC operated hooter cum flasher.

| Bullet Yards and Storage Yards | Gas Cylinder Storage and Gas Refilling Stations |

| Building Management Services | Breweries and Steel Plants |

| Gas Turbines and Heat Treatment Plants | Leak Detection, Solvent Vapors |

| Personal Monitoring and Compressor Stations | Pulp & Paper Industry and Fuel Loading Facilities |

| Shopping Malls and Gas Stations | Gas Cylinder Bank Areas |

| Chemical and Hazardous Areas Requiring Data Monitoring | Gas Pipeline Projects and Burner/Furnace Areas |