Our Standard Certifications

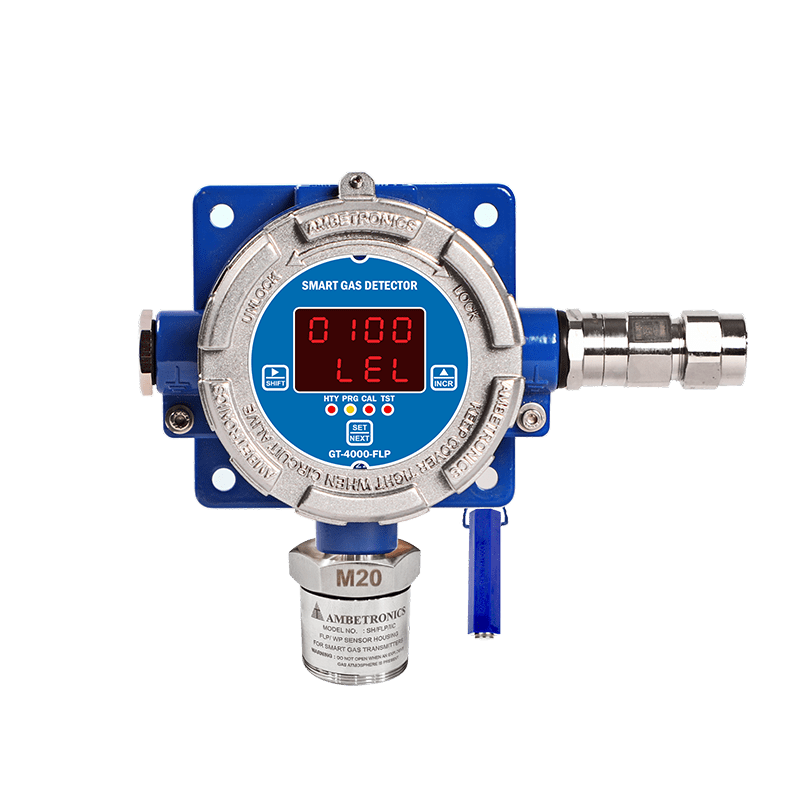

Combustible Gas Leak Detector (GT-4000-FLP)

The GT-4000-FLP Combustible Gas Leak Detector is a cutting-edge solution equipped with microcontroller-based technology, ensuring the latest, accurate, reliable, and high-performance capabilities. Its non-intrusive programming feature, facilitated by a Magnetic Wand in the Flameproof Model, enhances ease of use. The dual display system presents gas concentration and unit information separately, providing comprehensive monitoring. This detector offers programmable linear 4-20mA output proportional to gas concentration, making it compatible with Ambetronics controllers. Calibration at the site becomes a simple one-person task, thanks to its field-proven smart sensor. The password-protected programming ensures security, and the device holds approvals from CCOE, CMRI, as well as IP66 and IP68. Ideal for various applications, including oil and gas industries, chemical plants, refineries, and more, the detector is a versatile choice for hazardous areas. Its technical specifications include electrochemical/catalytic pellister detection methods, selectable gases and ranges, and LED indicators for different operational modes.

1. Advanced Technology: Combustible Gas Leak Detector utilizes microcontroller-based technology for the latest, accurate, reliable, and high-performance gas detection.

2. Non-Intrusive Programming: Flameproof Model offers non-intrusive programming using a Magnetic Wand, enhancing user convenience.

3. Dual Display: Equipped with dual displays – one for gas concentration and the other for the unit of gas, providing comprehensive monitoring.

4. Programmable Output: Combustible Gas Leak Detector generates a programmable linear 4-20mA analog output proportional to gas concentration, ensuring compatibility with Ambetronics controllers.

5. Ready for Integration: Designed to seamlessly integrate with Ambetronics controllers, ensuring ease of use in various applications.

6. One-Man Calibration: Calibration at the site is simplified and can be performed by a single person, enhancing efficiency.

7. Field-Proven Smart Sensor: Features a smart sensor with a proven track record in the field, ensuring reliability and accuracy.

8. Password Protection: Offers password-protected programming with the ability to change passwords, enhancing security.

9. Hazardous Area Approval: Holds approvals from CCOE, CMRI, and is IP66 & IP68 approved, making it suitable for hazardous areas.

Technical Specifications:

1. General:

– Detection Method:** Electrochemical / Catalytic Pellister

– Gases Detected:** Oxygen / Toxic / Combustible (Selectable Gas & Range)

– Display:** Dual 4-digit LED displays for gas concentration and unit of gas.

2. Performance:

– Accuracy: ± 2% of Full Scale at 20°C Temperature

– Response Time: T20 < 18 Seconds, T50 < 22 Seconds, T40 < 40 Seconds

– Start-up Time: Less than 30 Seconds.

3. Output Signal:

– Standard: Programmable Linear 4-20mA analog output.

4. Electrical:

– Supply Voltage: 18 to 36 VDC, Typically 24 VDC

– Power Consumption: Less than 3.6 Watts.

– Cable: For Flameproof Model: 3 Core wire, Shielded Armored Cable.

5. Error Monitoring:

– Display: Shows ‘OPEN’ for sensor break/open, ‘UNDR’ for under range, and ‘OUER’ for over range.

– Standard O/P Current: Up scale current: 21mA, Down scale current: 3.7mA (selectable).

6. Environmental:

– Operating Temperature: 0 to +50°C

– Storage Temperature: -10 to +60°C

– Humidity: Less than 95% Non-Condensing.

| Bullet yards and storage yards | Coal mines and confined areas |

| Gas pipeline projects and gas cylinder banks | Heat treatment plants and automotive industries, including paint shops |

| Burner and furnace areas | Stack monitoring and chemical storage areas |

| Ambient monitoring, sewage plants, and fertilizer plants | Power and industrial plants |

| Gas metering stations |