Our Standard Certifications

Conventional Multichannel Gas Monitor – UIP-1600 SERIES

The UIP-1600 Series is a state-of-the-art Conventional Multichannel Gas Monitor featuring 16 channels, each programmable with 4-20mA input. Utilizing microcontroller technology for enhanced accuracy, it offers easy field calibration through a front-panel membrane keypad. The device supports remote acknowledgment for relays and includes optional features like RS-485 Modbus serial port, serial printing port, and USB host for online/logged data reports. This gas monitor complies with various certifications, including CIMFR TR, PESO Cert., and BIS Mark License. It is designed for use in Almasphere Zone 1 and Zone 2, meeting IS/IEC standards for hazardous areas. The applications span diverse industries such as Fertilizer Plants, Oil & Gas, Chemical Storage, Refineries, Offshore Drilling, Gas Metering Stations, and more.

1. Microcontroller Technology:

– Multichannel Gas Monitor Utilizes the latest microcontroller-based technology for enhanced accuracy.

– Multichannel Gas Monitor Ensures precise and reliable gas monitoring in diverse industrial environments.

2. 16-Channel Input:

– Provides 16 programmable channels with 4-20mA input.

– Enables comprehensive monitoring capabilities across various gas detection points.

3. Easy Field Calibration:

– Facilitates straightforward on-line field calibration using a front-panel membrane keypad.

– Specification: Allows users to maintain accuracy and optimize performance with minimal effort.

4. Programmable Scan Time:

– Field programmable channel scan time ranging from 1 to 240 seconds.

– Specification: Offers flexibility in adjusting the scanning intervals based on monitoring requirements.

5. Remote Acknowledgement Facility:

– Supports remote acknowledgment for relays.

– Specification: Enhances operational efficiency by allowing users to manage relays remotely.

6. Optional Communication Ports:

– Options for RS-485 Modbus serial port, serial printing port, and USB host.

– Specification: Enables versatile connectivity for data reporting and integration with other systems.

7. Compliance and Certifications:

– CIMFR TR, PESO Cert., BIS Mark License, and Almasphere Zone 1 and Zone 2.

– Complies with industry standards and safety regulations for hazardous environments.

8. Dual Set Points and Relay Outputs:

– 2 independent user programmable set points for each channel.

– Specification: Allows customization of alarm thresholds with relay outputs for enhanced safety measures.

9. Performance Monitoring:

– Monitors gas detector error conditions such as ‘Break/Open’ and under/over range.

– Specification: Enhances system reliability by providing real-time error condition indications.

10. Wide Operating Voltage Range:

– Feature: Operates on 90 to 270 VAC, 50Hz, or 110 VDC to 270VDC.

– Specification: Accommodates diverse power supply conditions for increased operational flexibility.

11. Environmental Adaptability:

– Feature: Operating temperature range of -10°C to 60°C and below 95% non-condensing humidity.

– Specification: Suitable for a wide range of environmental conditions in various industries.

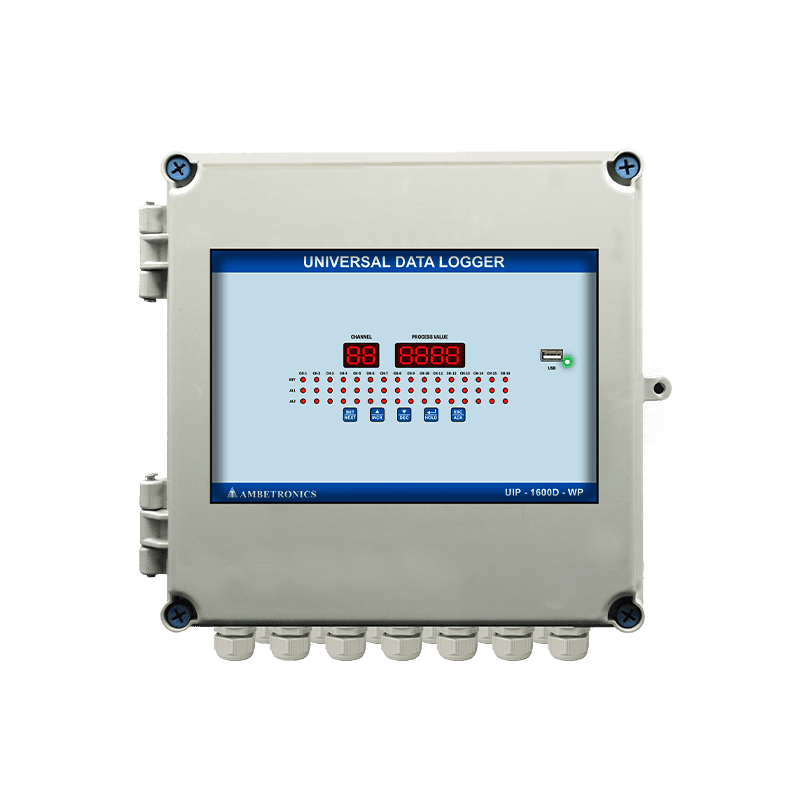

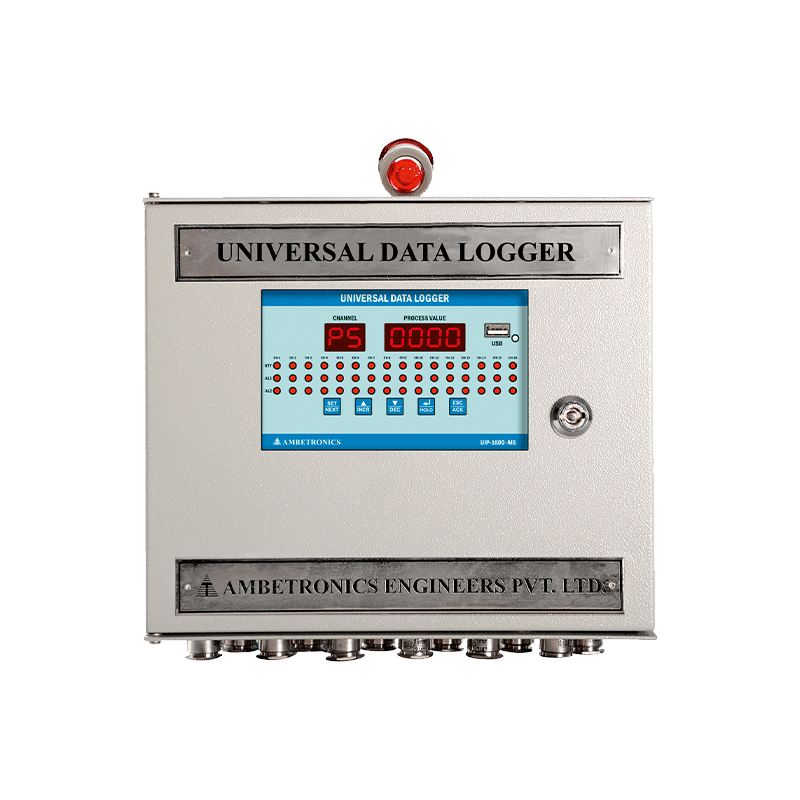

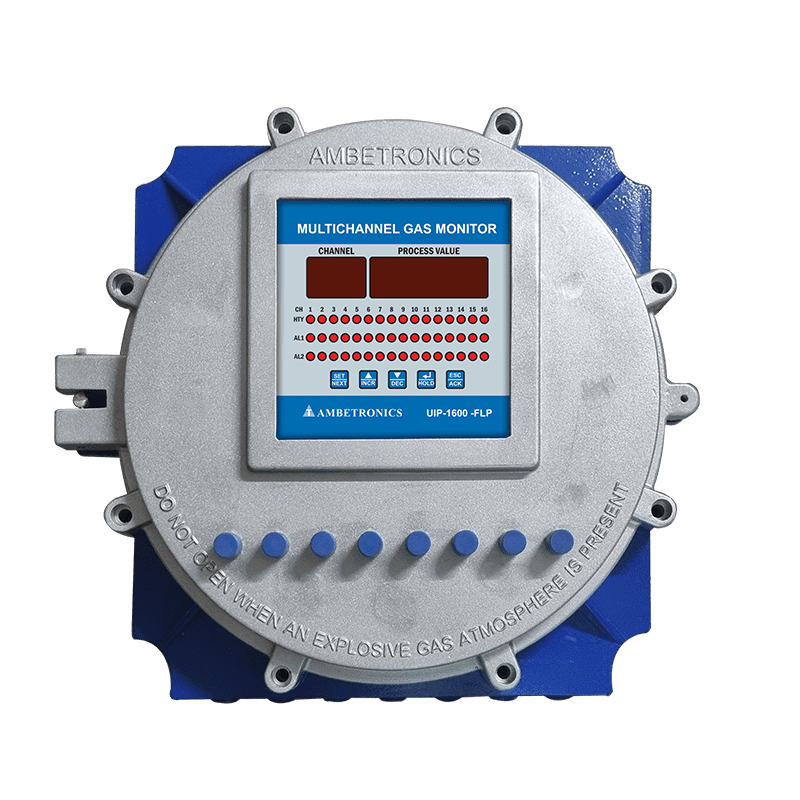

12. Housing Options:

– Feature: Weatherproof (IP-65), Flameproof (IP-66), and MS Panel Housing.

– Specification: Offers flexibility in choosing housing based on installation requirements and environmental conditions.

13. Optional Features:

– Feature: Isolated RS-485 serial ports, external relay modules, direct printout on Dot Matrix serial printer, USB host connectivity.

– Specification: Enhances functionality with optional features tailored to specific user needs.

14. Data Logging and Reporting:

– Feature: Logging interval of 1 to 9999 seconds for data logger models.

– Specification: Supports efficient data logging and reporting capabilities for comprehensive analysis.

15. Dimensions and Mounting Options:

– Feature: Compact dimensions and wall/stand mounting options.

– Specification: Offers flexibility in installation and space utilization.

16. Weight:

– Feature: Lightweight design.

– Specification: Facilitates easy handling and installation.

| Fertilizer Plants | Oil & Gas Industries |

| Chemical Storage Area | Refineries |

| Chemical Processing Plants | Offshore Drilling & Processing Platforms |

| Gas Metering Stations | Bullet Yards and Storage Yards |

| Gas Pipeline Projects | Chemical & Petrochemical Plants |

| Hotel Industries | Power Industrial Plants |