Our Standard Certifications

CRM-131-1 | Clean Room Differential Pressure Monitor

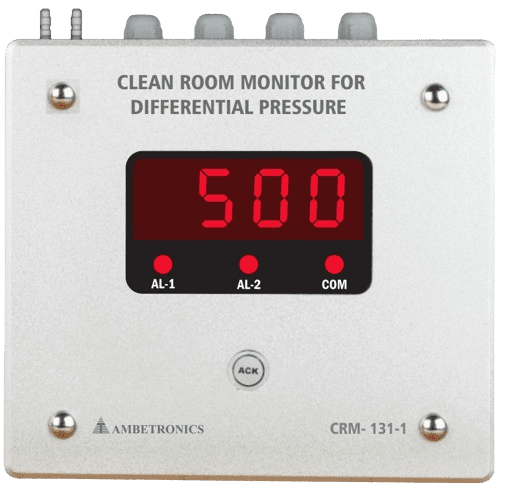

The Clean Room Differential Pressure Monitor CRM-131-1 is a state-of-the-art monitoring device designed for precision in clean room environments, particularly in pharmaceutical, HVAC, animal house clean rooms, and cold storage applications. Its 7-segment LED display provides accurate readings for differential pressure with a range from -100 to 100 mmWC, offering a resolution of 0.1.Equipped with two user-programmable alarms (AL1 and AL2) and an integrated buzzer, the monitor ensures immediate notification of pressure limit violations. The device supports software calibration, indicating when calibration is due or when the sensor requires replacement.

1. High-precision Monitoring: The Clean Room Differential Pressure Monitor CRM-131-1 ensures accurate and reliable monitoring of differential pressure in clean room environments.

2. 7-Segment LED Display: Clean Room Differential Pressure Monitor Equipped with a 7-segment LED display, the monitor provides a clear and easy-to-read indication of the differential pressure.

3. User-Programmable Alarms: Users have the flexibility to set two alarms, AL1 and AL2, based on their specific requirements for pressure limits.

4. Integrated Buzzer: The monitor features an integrated buzzer that immediately signals alarm violations, allowing for prompt attention and corrective action.

5. Inbuilt Calibration Facility: Offering Inbuilt calibration, the device provides convenience in maintaining accurate pressure measurements over time. It also indicates when calibration is due or when sensor replacement is necessary.

6. Password Protection: Enhanced security with password-protected programming ensures authorized access and prevents unauthorized changes to settings.

7. RS-485 Communication: The isolated RS-485 communication with Modbus RTU Protocol allows seamless integration with various systems, including PLCs and SCADA.

8. Optional Built-in Relays: The monitor provides the option for two built-in relays with DPDT ratings of 2A/24VDC each, offering additional control capabilities.

Technical Specifications:

1. Sensor: Built-in differential pressure sensor with Chrome-Plated Brass Hose Nozzles for +Ve and -Ve pressure connections.

2. Accuracy: Differential Pressure: ± 1% F. S

3. Display: 4-digit Seven Segment 1” Red LED for Differential Pressure, Status LEDs for Alarms (AL1 and AL2) and Communication (COM).

4. Audio Indication: Integrated buzzer for Alarm limits violation.

5. Output (Optional): 2 Nos. DPDT relays (2A/24VDC).

6. Communication: Isolated RS-485 with Modbus RTU Protocol, programmable settings for baud rate, parity, data bits, stop bits, slave ID, and minimum polling rate.

7. Programmable Parameters: Set points for AL1 and AL2, user-programmable alarm logic (High or Low).

8. Environmental Conditions:

– Operating Ambient Temp.: 0 to 50°C

– Humidity: Below 95% RH, Non-condensing.

9. Electrical:

– Supply Voltage: 18 to 36VDC (Typically 24VDC)

– Power Consumption: Less than 1.2 watts at 24VDC.

10. Dimensions:

– Flush Mounting Plate: Aluminium SS-304

– Front Plate Size: 185 mm (H) x 200 mm (W)

– Back Enclosure: MS with powder-coated finish

– Overall Dimension: 185mm (H) x 200 mm (W) x 50 mm (D)

– Mounting: Modular wall mounting with SS or Aluminium front.

| Clean room application in Pharmaceutical industry |

| Pharma Environment monitoring applications |

| HVAC (Heating, ventilation, Air conditioning, Cooling) |

| Animal house clean room |

| Cold Storage |