Our Standard Certifications

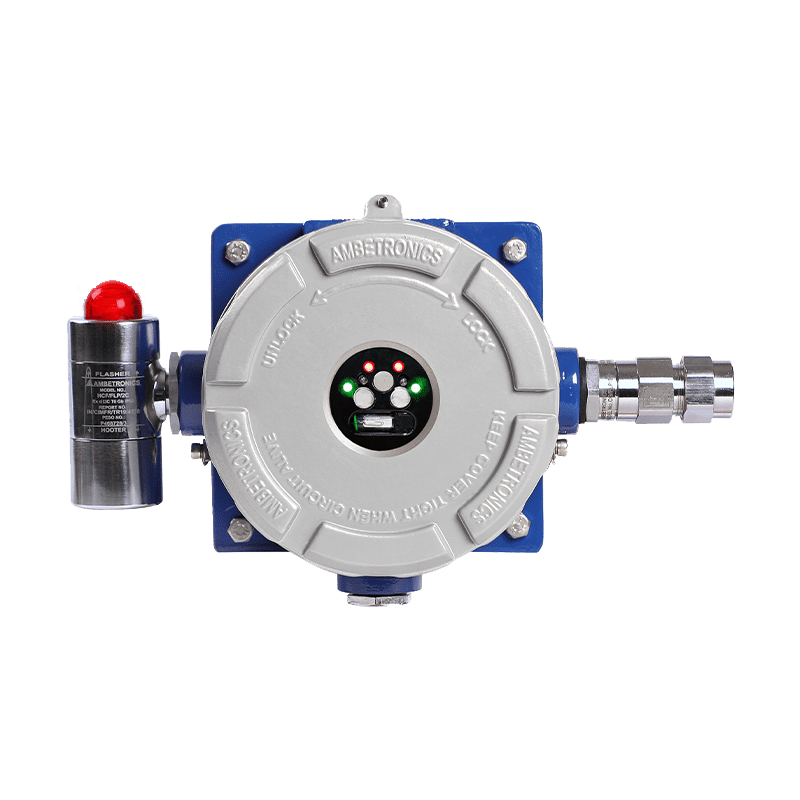

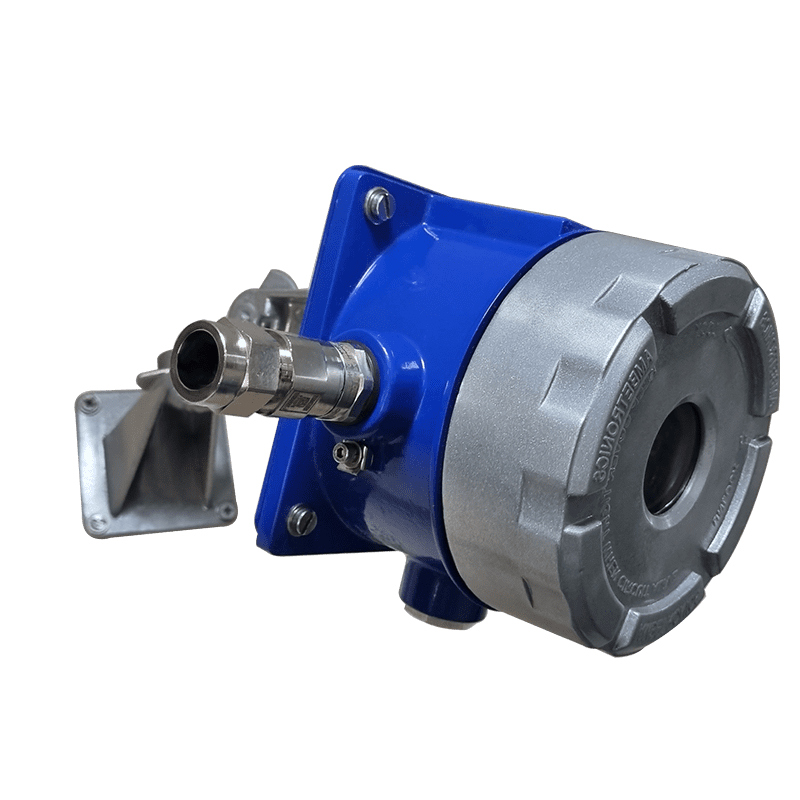

Flame Detector FLD-3311-FLP | UV and Triple IR Sensor

The FLD-3311-FLP is a highly advanced UV and Triple IR Flame Detector designed for effective fire detection across various industrial applications. Its Multi-Spectral Sensitivity utilizes UV and IR sensors, offering a clear line of sight visual range with triple spectrum design for long-distance flame detection and excellent false alarm immunity. The detector ensures no zone crossover detection through sensitivity selection and boasts high sensitivity coupled with a fast response time for rapid and accurate flame detection. Featuring multiple output options, including relays, 0-20mA, and 0-10V, the detector provides flexibility and compatibility. It supports user programmability via Bluetooth, HART, or RS-485, and includes optional features like heat detector extension, air shield for clean optics, built-in self-test (BIT), and mobile alert capabilities. Connectivity options extend to IoT for enhanced monitoring. The detector holds certifications for flameproof applications, complying with IS/IEC standards and boasting approvals such as Ex d IIC T6 Gb and IP68. With a wide range of applications, including chemical plants, refineries, power generation, and aerospace, the UV and Triple IR Flame Detector ensures reliable and efficient flame detection in diverse environments.

1. Multi-Spectral Sensitivity: UV and Triple IR Sensor Flame Detector Detects fires using UV and IR sensors, providing a comprehensive approach to flame detection.

2. Clear Line of Sight Visual Range: UV and Triple IR Sensor Flame Detector offers a specific visual range for effective detection, ensuring no compromise in surveillance.

3. Triple Spectrum Design: Enhances detection capabilities for long distances while maintaining excellent immunity to false alarms.

4. Sensitivity Selection: Allows users to customize sensitivity levels, preventing zone crossover detection.

5. High Sensitivity and Fast Response Time: Ensures rapid and accurate flame detection, critical for timely response in emergency situations.

6. Multiple Output Options: Provides flexibility with (3) relays for flame detection, auxiliary, and fault, along with 0-20mA or 0-10V output.

7. User Programmable: Configurable via Bluetooth, HART, or RS-485 for ease of setup and customization.

8. Optional Features:

– Heat detector extension

– Air shield for clean optics

– Built-in self-test (BIT)

– Mobile alert via LoRa/WiFi

– IoT connectivity

Technical Specifications:

1. Spectral Response:

– UV Band: 185nm to 260nm

– Three IR Bands: 3000nm to 5000nm

2. Detection Range:

– n-Heptane: 88ft (27m)

– Kerosene: 82ft (25m)

– Diesel Fuel: 82ft (25m)

– Methanol: 66ft (20m)

– Gasoline: 82ft (25m)

3. Performance:

– Response Time: Typically less than 5 seconds

– Field of View: 90° Horizontal, 90° Vertical

– Adjustable Time Delay: Up to 30 seconds

– Adjustable Sensitivity: Low, Medium, and High

– BIT: Automatic self-check test

– Performance Test: Compatible with Test Lamp (F TU-3311)

4. Electrical:

– Supply Voltage: 18 to 36 VDC, typically 24VDC

– Power Consumption: Less than 3W

5. Output Signal:

– 4-20mA Current Output or 0-10V

– L.E.D. Indication: POWER LED (Green), FIRE DETECT LED (RED), COMMUNICATION LED (Blue)

– Relay: Three SPDT relays 6A@30VDC & 250VAC for Fail safe, Fire detection, and Auxiliary output.

– Communication: RS-485 communication port with MODBUS RTU protocol.

– HART Protocol: Optional for configuration changes using AEPL Communicator

– Connectivity (optional): Mobile connectivity and SMS alert via LoRa & IoT support

6. Environmental:

– Operating Temperature: -40°C to +85°C

– Storage Temperature: -50°C to +90°C

– Humidity: Less than 95% Non-Condensing

7. Flameproof Housing:

– Degree of Protection Class: IP66 & IP68

– Housing Material: Cast Aluminium LM6 alloy or Stainless Steel

– Cable Entry: Flameproof, IP66 Double Compression Cable Gland – M20 x 1.5 (P)

– Wiring: 16-26AWG (1.5mm – 0.14mm)

– Dimension: Various dimensions for different enclosures and configurations

– Mounting: Wall or Pipe Mounting

– Weight: Varies based on enclosure type (IIC or JB-90)

| Chemical and Petrochemical plants | Refineries |

| Onshore & Offshore Oil & Gas Installation & Pipelines | Hazardous Storage Tank Farms |

| Automotive industry (Paint Booth, Paint Kitchen, Production Line) | Printing Industry |

| Textile Industries | Engine Test Cells/Room |

| Fuel and gas processing and storage facilities | Power Generation |

| Explosives and munitions | Fertilizer Plants |

| Vehicle battery charging stations | Aerospace industry (Aircraft Hangars) |

| Waste management facilities | Pharmaceutical Industry |

| Hazardous materials storage areas | Food Processing |

| Warehouses | Indoor Diesel Storage & Process |

| Manufacturers & Automation Industries | Power Plants/ Nuclear Power Sites |