Our Standard Certifications

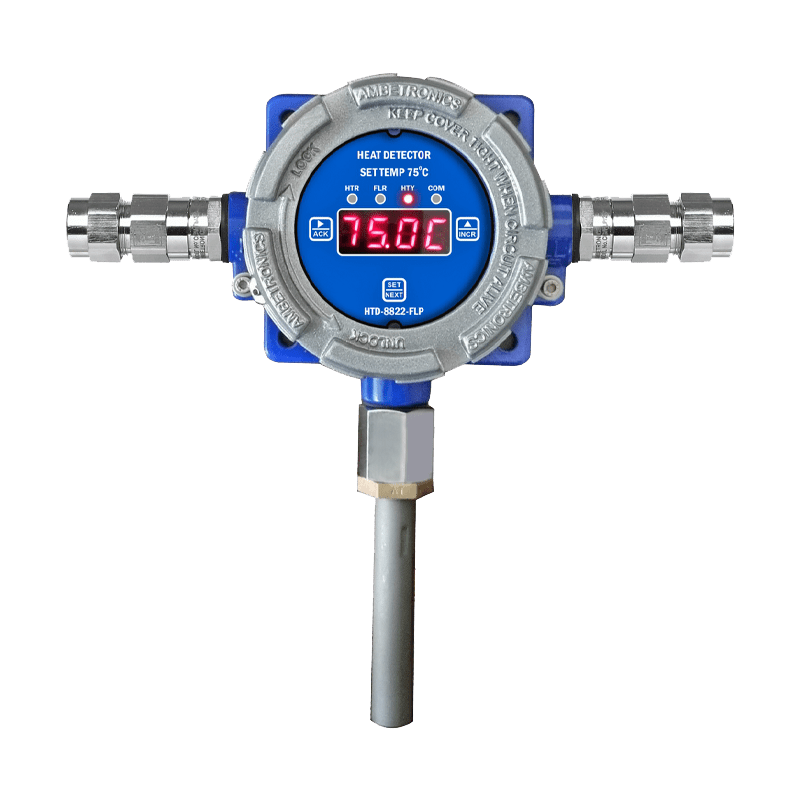

Heat Detector HTD-8822-FLP

The HTD-8822-FLP Heat Detector is a sophisticated and reliable thermal detection device designed to sense overheating or fire through temperature rise in various applications. This Micro-Controller based detector offers a fast and accurate response to heat build-up in ambient temperature, providing a crucial alarm signal to alert the system and trigger precautionary measures. Factory preset to customer-specified temperatures between 40°C to 210°C, the detector features auto-reset functionality, low power consumption, and seamless communication with the GDS-416 system. With a fixed temperature, rate-compensated thermal detection technique, the HTD-8822-FLP is suitable for diverse environments such as heat treatment plants, burner/furnace/boiler areas, oil & gas industries, and more. Its performance is marked by a rapid response time of less than 60 seconds. The electrical aspects include a supply voltage range of 18 to 36 VDC, consuming less than 3W power. The detector utilizes flexible or armored shielded cables for wiring, supporting both Class A and Class B looping.

1. Micro-Controller Based Design:

– Heat Detector utilizes advanced micro-controller technology for enhanced reliability and accuracy.

2. Fast and Reliable Response:

– Heat Detector detects heat build-up or rise in ambient temperature swiftly, providing a prompt and reliable response.

3. Factory Preset Temperature:

– Factory preset to customer-specified temperatures between 40°C to 210°C, ensuring suitability for diverse applications.

4. Auto-Reset Operation:

– Self-resetting capability after the temperature cools down, ensuring continuous monitoring without manual intervention.

5. Low Power Consumption:

– Consumes less than 3W, contributing to energy efficiency and cost-effectiveness.

6. Communication with GDS-416:

– Designed to seamlessly communicate with the GDS-416 system, facilitating integration into larger monitoring setups.

7. User-Friendly Operation:

– Plug-and-play functionality for easy installation and operation, with straightforward testing procedures.

8. Visual Display Indication:

– Equipped with four LEDs, including two for warning signals, one for power/health status, and one for communication status.

9. Dedicated Hooter cum Flasher Port:

– Provides a dedicated port for connecting a hooter cum flasher, enhancing the alarm notification system.

10. No Maintenance, No Calibration:

– Requires no regular maintenance or calibration, reducing the overall cost of ownership.

Technical Specifications:

1. Detection Technique:

– Fixed temperature, rate-compensated thermal heat detection for precise monitoring.

2. Rated Alarm Temperature:

– Adjustable between 40°C to 210°C, meeting specific customer requirements.

3. Auto-Reset:

– Automatically resets itself after the temperature cools down, ensuring continuous operation.

4. LED Indicators:

– Four LEDs for visual indications – two for warning, one for power/health, and one for communication status.

5. Response Time:

– Rapid response time of less than 60 seconds, minimizing potential delays in alerting.

6. Electrical Requirements:

– Operates on a supply voltage range of 18 to 36 VDC, typically 24 VDC, with low power consumption (<3W).

7. Wiring:

– Uses 1.5mm flexible or armored shielded cable for supply and output, with two pairs of black-white wires for Class A and Class B looping.

8. Output Signal:

– Provides potential-free Normally Open (NO) contact, with a maximum load capacity of 680 ohms.

– Communication supported through RS-485 MODBUS Protocol.

9. Mechanical Construction:

– Stainless steel sensing shell for durability.

– Aluminum LM6 enclosure, compact in size (254mmW x 257mmH x 97mmD), suitable for wall, stand, and pipe mounting.

10. Weight:

– Approximately 2kg for the body, ensuring easy installation and relocation.

| Heat Treatment Plants | Burner / Furnace / Boilers Areas |

| Oil & Gas Industries | Ambient Monitoring |

| Gas Pipeline Project Refineries | Gas Refilling Station |

| Offshore Drilling & Processing Platform | Commercial Kitchen |

| Chemical & Petrochemical Plants | Gas Manifold Area |

| Paint Spray Booths | Automotive Industrial |

| Power & Industrial Plants |