Our Standard Certifications

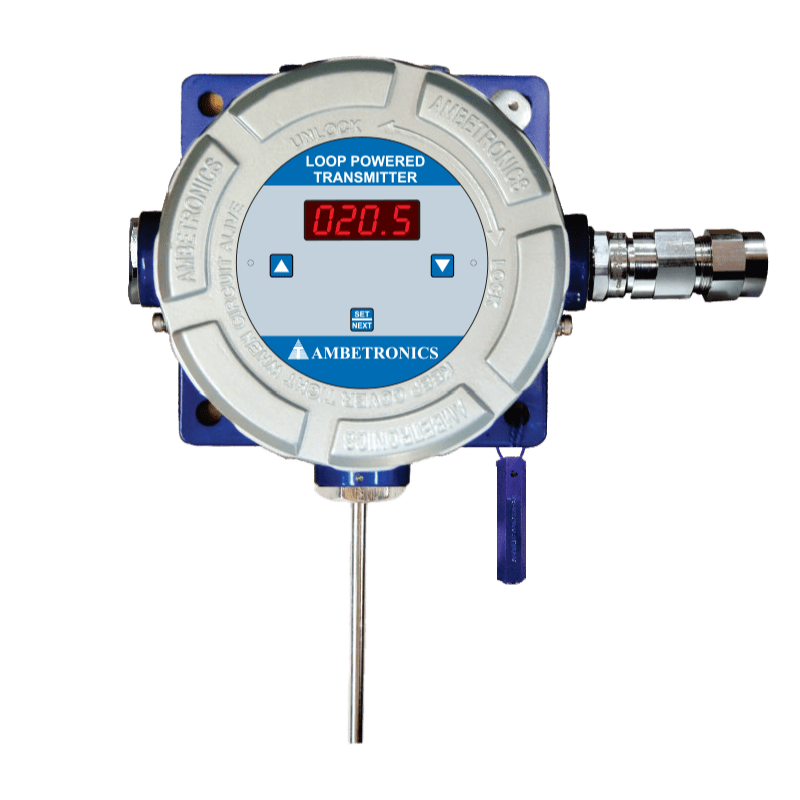

Loop Powered Temperature Transmitter | TMP-215 (LED DISPLAY)

The TMP-215-FLP Loop Powered Temperature Transmitter offers a highly reliable and accurate solution for temperature sensing across various industrial applications. With fixed input compatibility for RTD, J, K, R, and S types, it ensures versatility in monitoring temperature across diverse environments. Its user-friendly interface and easy installation make it accessible for operators, while features like automatic cold junction compensation and software calibration enhance its performance and reliability. The transmitter operates within a wide range of temperatures (-40°C to 85°C) and is designed to withstand harsh environmental conditions, with options for weatherproof, panel mount, or flameproof housings. Its loop output adheres to industrial standards, providing a 4-20mA output proportional to the input signal. Error monitoring capabilities ensure prompt detection of sensor faults or abnormalities, enhancing operational efficiency and safety. Whether in chemical plants, power stations, or manufacturing facilities, the TMP-215-FLP offers a robust solution for precise temperature monitoring, contributing to enhanced process control, reduced maintenance costs, and improved safety standards.

1. Highly Reliable Sensing Technology: Loop Powered Temperature Transmitter ensures accurate and dependable temperature readings for precise process control.

2. Fixed Input Compatibility: Loop Powered Temperature Transmitter supports various input types including RTD, J, K, R, and S, enhancing versatility across different applications.

3. User-Friendly Operation: Simple interface and easy installation facilitate convenient usage for operators.

4. Intelligent Power-On Startup: Self-driven menu system enables quick and hassle-free startup.

5. Easy-to-Read Display: Provides clear and fast response for efficient monitoring.

6. Password Protection: Secure programming with password protection and change facility ensures data integrity and unauthorized access prevention.

7. Software Calibration: No need for trimpots, simplifying calibration processes and reducing maintenance requirements.

8. Industrial Standard Output: Offers a 4-20mA output in line with input signal, ensuring compatibility with existing systems.

9. Built-In Reverse Polarity Protection: Safeguards against potential damage due to incorrect power connections.

10. Reduced Maintenance and Installation Costs: Long-term stability and easy installation contribute to lower operating expenses.

11. Non-Intrusive Programming (Flameproof Model): Utilizes magnetic pen for programming, maintaining safety in hazardous environments.

Technical Specifications:

1. Compensation: Automatic cold junction compensation for thermocouples (J, K, R, & S types), with specified cable length during order.

2. Sensor Probe Details: Customizable options available upon ordering.

3. Loop Output: Industrial standard 4-20mA output, suitable for a permissible load of 750 ohms at 24VDC, 25mA.

4. Electrical Supply Voltage: Operates within a range of 14 to 36VDC, typically 24VDC with a current draw of 25mA.

5. Operating Temperature: Capable of functioning in temperatures ranging from -40°C to 85°C.

6. Humidity: Designed to operate below 95% non-condensing humidity levels.

7. Error Monitoring:

– Display: Indicates sensor faults such as ‘Open/Break’, ‘Under’, or ‘Over’ range conditions.

– Loop Current: Programmable scale with up to 21mA for upscale and 3.7mA for downscale current.

8. Housing Options:

– Weatherproof Housing: IP65 rated polycarbonate construction with dimensions of 120(H) x 100(W) x 55(D) mm.

– Panel Mount Housing: IP40 rated ABS plastic housing, measuring 96(H) x 96(W) x 85(D) mm.

– Flameproof Housing: IP66/IP68 rated cast aluminum or stainless steel construction with dimensions of 145(H) x 185(W) x 100(D) mm. Certified by CIMFR and PESO for -hazardous environments.

| Oven, BOD, Incubator, Humidity Chamber | Monitoring Generators, Bearings, Motors, Transformers |

| Foundries for Heat Treatment | Chemical and Hazardous Area Monitoring |

| Iron and Steel Industry | Cement Plants for Process Automation |

| Water Purification and Treatment | Temperature Scanning of Boilers |

| Sugar Industry | Paper and Pulp Industry |

| Chemical and Petrochemical Industries | Water Pumping Stations |

| Power Plants |