Our Standard Certifications

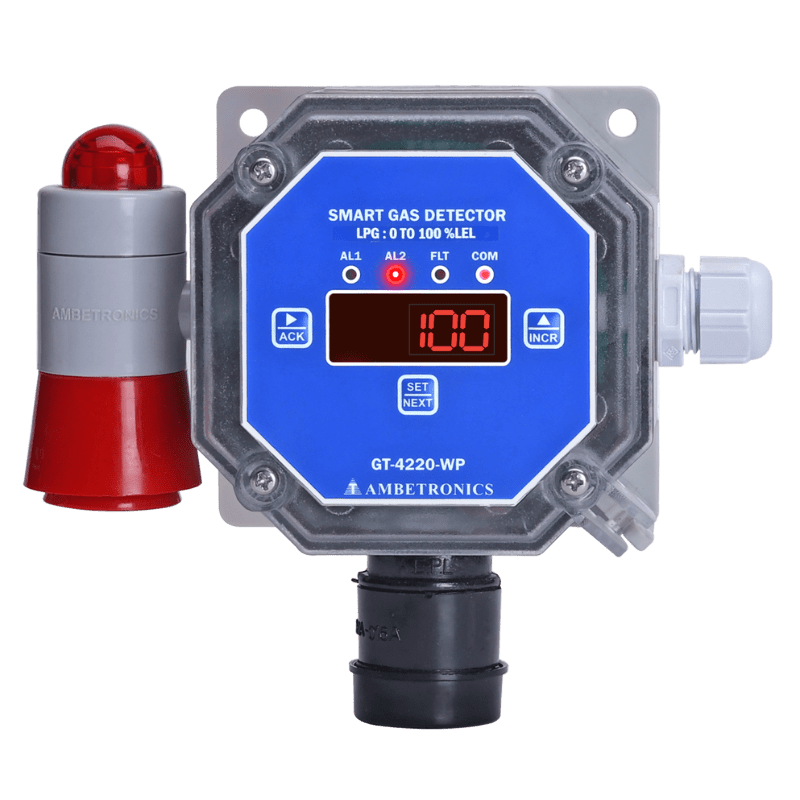

Combustible Gas Leak Detector – GT-4220-WP

The GT-4220-WP-HCF is a versatile LPG/PNG/CNG Gas Leak Detector or (Combustible Gas Leak Detector) designed for various applications, including gas metering, CNG stations, oil and gas industries, refineries, commercial kitchens, chemical plants, and more. It features self-test functionality, a built-in temperature sensor, and a PESO Certified Enclosure with a hooter cum flasher for reliable gas leak detection. Utilizing Catalytic/Pellistor/Semiconductor technology, the detector ensures fast and precise responses to the presence of flammable gases such as LPG, PNG, CNG, LNG, and natural gas. The sensor is highly resistant to poisoning and etching, enhancing durability. The device comes with an isolated RS-485 communication port using MODBUS RTU protocol for efficient data transfer. Non-intrusive programming with a magnetic wand, password-protected menu, and optional integrated buzzer and flasher further enhance its user-friendly features.

1. Self-Test Facility:

– The gas leak detector includes a self-test feature for regular self-diagnosis, ensuring continuous reliability.

2. Built-In Temperature Sensor:

– Gas Leak Detector Equipped with an integrated temperature sensor for ambient temperature measurement, enhancing overall safety measures.

3. Hooter Cum Flasher:

– Features an audible hooter and visual flasher for immediate and effective alerting in case of gas leaks.

4. Cable Gland:

– Includes a cable gland for secure cable connections, contributing to the overall robustness of the device.

5. Multiple Gas Detection Technologies:

– Utilizes Catalytic, Pellistor, or Semiconductor technology for detecting a wide range of flammable gases, including LPG, PNG, CNG, LNG, and natural gas.

6. Highly Resistant Sensor:

– The gas sensor is highly resistant to poisoning and etching, ensuring longevity and consistent performance.

7. Isolated RS-485 Communication:

– Features an isolated RS-485 communication port with MODBUS RTU protocol for efficient and secure data transmission.

8. Non-Intrusive Programming:

– Allows non-intrusive programming using a magnetic wand, eliminating the need to open the enclosure cover for adjustments.

9. Password-Protected Menu:

– The programming menu is password-protected, enhancing security and preventing unauthorized access.

10. Optimized for Small Gas Leaks:

– Specifically designed and optimized for the detection of the smallest gas leaks, ensuring comprehensive safety coverage.

11. Integrated Buzzer and Flasher (Optional):

– Offers an optional integrated buzzer and flasher for enhanced audible and visual alerts.

12. Alarm Relay Contacts:

– Two alarm relay contacts are configurable for warm, alarm, and fault conditions, providing flexibility in monitoring.

13. Ambient Temperature Detection:

– Inbuilt ambient temperature detection capability enhances overall environmental monitoring.

Technical Specifications:

1. Gas Sensor:

– Catalytic / Pellistor / Semiconductor

2. Sensor Holder:

– SS-316

3. Temperature Sensor:

– For Ambient temperature measurement

4. Detection Method:

– Continuous Diffusion

5. Range & Resolution:

– As specified in the table

6. Display & LEDs:

– 4 Digit Seven-segment LED Display

– LEDs for Warn, Alarm, Fault, and Communication status

7. Set Point:

– Two independent alarm set points for AL1 & AL2

– User-selectable hysteresis and logic options for alarms

8. Accuracy:

– Catalytic / Pellistor: ± 2% full scale

– Semiconductor: ± 5% of full scale (for gas detection only)

9. Response Time:

– Less than 5 seconds

11. 10 Start-up Time:

– Less than 30 seconds

12. Supply Voltage:

– 18 to 36 VDC, Typically 24VDC

13. Power Consumption:

– Less than 2 Watts

14. Connector:

– 4 wires (1.5mm) for 24 VDC input & RS-485 Output

– 4 wires (1.5mm) for Relay Output

15. Operating Temperature:

– -20 to +60°C

16. Storage Temperature:

– -30 to +70°C

17. Humidity:

– Less than 95% Non-Condensing

18. Output Signals:

– Two SPST NO/C/NC relay contacts (5A/250VAC, 5A/30VDC)

– Isolated RS-485 communication with MODBUS RTU protocol

– SS 316 PESO Certified Hooter Cum Flasher (90dB) with RED light flashing.

19. Error Monitoring:

– Displays ‘Sensor Open/Over Range’ during sensor break/open

– Activates alarm relay if ambient temperature exceeds set point

20. Weatherproof Housing:

– Protection class: IP (Specify the IP rating)

– Cabinet material: Polycarbonate, Grey Color

– Cable entry: Thermoplastic cable gland (IP-68)

– Dimensions: 170.6 mm (H) with sensor holder x 175 mm (W) with cable gland & Hooter cum Flasher x 70 mm (D)

– Mounting: Wall Mounting/Stand Mounting

– Weight: Approximately 380 grams.

21. Common Deliverables:

– Test Calibration Certificate

– Reference Calibration Gas Certificate

– Operational/Instrument User Manual

– Standard Mounting Hardware

– Protection Cap

– Calibration Cap

– Magnetic Wand

22. Optional Accessories:

– Certified 24 VDC Power Supply

– Canopy & Mounting Stand

– Flameproof, Weatherproof IP66 Hooter Cum Flasher (Model No.: HCF/FLP/2C) with CIMFR and PESO Certifications.

| CNG station | Fertilizers Plants |

| Oil & Gas Industries | Ambient Monitoring |

| Gas Pipeline Project Refineries | Gas Metering Station |

| Gas Refilling station | BMS |

| Commercial Kitchen | Gas manifold area |

| Chemical & Petrochemical Plants | Automotive Industrial / Paints Shops |

| LPG Gas Cylinder Bank | Sewage Plants |

| Burner / Furnace Areas | Heat Treatment Plants |

| Chemical Storage Area | LPG Bullet Yards |

| Chemical Processing Plant | Offshore Drilling & Processing Platform |

| Power & Industrial Plants | Gas Metering Skid |