Our Standard Certifications

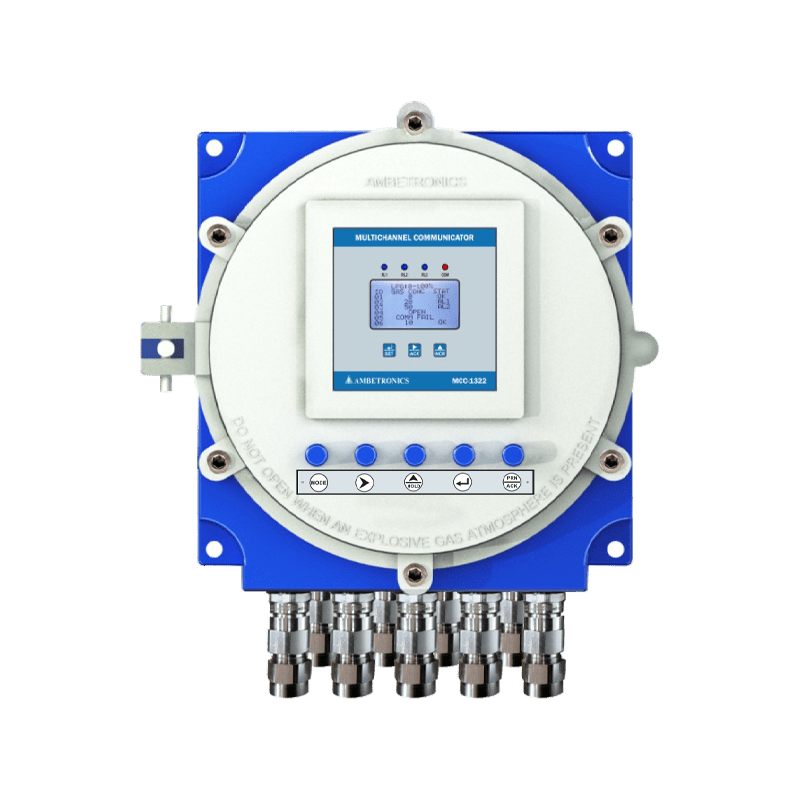

Multichannel Communicator MCC-1322-FLP

The MULTICHANNEL COMMUNICATOR MCC-1322-FLP is a versatile monitoring system designed for applications requiring comprehensive data acquisition from up to 80 detectors with RS-485 Modbus RTU connectivity. Its advanced features include a ring topology for redundancy, support for 20 Relay Modules, and multidrop RS-485 port, streamlining cabling. The device boasts a 128×64 Graphical LCD display for clear data visualization and supports a common alarm setting for all 80 channels, enhancing efficiency. The system includes error detection for ‘Detector Open/Communication Break,’ ensuring fail-safe operation. An integrated buzzer and 3 DPDT Relays provide audible and visual alarms. With a password-protected menu, easy programming through front panel keys, and programmable parameters like alarm set points, logic, and hysteresis, the MCC-1322-FLP offers flexibility. Communication settings such as MODBUS RTU protocol, selectable baud rates, and polling intervals enhance adaptability.

1. Modular Connectivity: Multichannel Gas Communicator supports up to 80 detectors with RS-485 Modbus RTU network connectivity, enhancing monitoring capabilities.

2. Redundancy Options: Multichannel Gas Communicator allows for a ring topology, providing redundancy and ensuring continuous operation in critical applications.

3. Relay Module Integration: Connects to a maximum of 20 Relay Modules (REL-1200), with each module featuring 2 DPDT relays for comprehensive alarm handling.

4. Multidrop RS-485 Port: Enables efficient cabling by eliminating the need for separate cables to each detector, communicator panel, and Relay Module.

5. Configurable Polling Interval: User-selectable polling intervals (500mSec/1000mSec) for tailored data acquisition and system responsiveness.

6. Graphical LCD Display: Features a 128×64 Graphical LCD display with backlight, ensuring easy readability of data and system status.

7. Common Alarm Setting: Streamlines operation by allowing a common alarm setting for all 80 channels, saving time and effort in individual configurations.

8. Error Detection: Detects ‘Detector Open/Communication Break’ errors and displays messages for prompt identification and resolution.

9. Integrated Buzzer and Relays: Ensures fail-safe operation with an integrated buzzer and three DPDT Relays (AL1, AL2, Fault) for alarm set points.

10. Password-Protected Menu: Enhances security with a password-protected menu, providing controlled access to programming features.

11. User-Friendly Interface: Easy handling and programming facilitated by three front panel keys for intuitive operation.

Technical Specifications:

1. Input:

– 80 detectors with RS-485 Modbus RTU port (Slave Id=1 to 80).

– 20 Relay modules (REL-1200) with IDs ranging from 81 to 100.

2. Display:

– 128×64 Graphical Display with Backlight.

3. Communication Setting:

– Protocol: MODBUS RTU.

– Baud Rate: User-selectable (9600/19200/38400/57600)bps.

– Parity: User-selectable (Odd/Even/None).

– Stop Bits: User-selectable (One/Two).

– Polling Interval: User-selectable (500ms/1000ms).

4. General Error Monitoring:

– Detects ‘Detector Open/Communication Break’ errors and activates fault relay for fail-safe operation.

5. Relay:

– Three DPDT Relays with potential-free contacts (2 NO-C-NC) common for all configured detectors.

6. Programmable Parameters:

– Alarm Set Points: Two (AL1 and AL2), user-programmable.

– Logic: User-programmable (High/Very High, Very Low/Low, Low/High).

– Hysteresis/Time Delay/Snooze: User-programmable.

– Relay Assignment: Configurable for Alarm 1, Alarm 2, and fault (fail-safe operation).

– Latch: Programmable as ‘Enable/Disable’ for Alarm 1 and Alarm 2.

7. Electrical:

– Supply Voltage: 90VAC to 270VAC, 50Hz.

– Power Rating: Less than 80W @240VAC.

– Supply for Detector & Relay Module: 24VDC, 4.5A.

– Cable Cross Section: 2.5mm².

– Cable Required: 2.5mm², 4 core Shielded Armoured/Twisted flexible cable for signals.

8. Environmental:

– Operating Temp.: 0 to 50°C.

– Relative Humidity: Below 95%, RH, Non-condensing.

9. Accessories:

– FLP/WP Junction box enclosure, Relay Module (REL-1200), Hooter cum flasher, RS-485 to RS-232/USB/Ethernet/Wi-Fi Converter.

10. Dimensional Details:

– Degree of Protection Class: IP-66.

– Housing Material: Cast Aluminum LM6 Alloy or cast Iron (C.I.).

– Cable Entry: Flameproof, Weatherproof IP66 Double compression cable gland.

11. Certifications:

– CIMFR Certificate No.: CIMFR/TC/P/1923 Dt.: 26/08/2019.

– PESO Certificate No.: P468728/1 Dt.: 21/02/2020.

| Clean Room Monitoring & Validation in Pharmaceutical, Laboratories, Bioscience. | Room Mapping in Pharmaceutical. |

| Pharmaceutical process validation with graph & scale report in Autoclave. | Healthcare, Hospitals, Shopping Malls. |

| Breweries, Steel Plants, Gas Turbines. | Leak detection, Solvent Vapours. |

| Personal Monitoring, Compressor Stations. | Emergency response, Equipment Maintenance. |

| Pulp & Paper Industry, Fuel Loading Facilities. | Waste Water Treatment Plants, level sensing & control. |

| Refineries & Petrochemical Plants Including Offshore. | Drilling & Plant Shut-downs. |

| ISO Certification Records, Validation process certifying. | Chemical & Hazardous area where data monitoring is essential. |

| Cold Storage & Chilling Plant. | Building Management & Energy Saving Systems. |

| Meteorological, Weather Forecast Applications. | Remote Indication location on tank taps as used in liquid level sensing & control. |