Our Standard Certifications

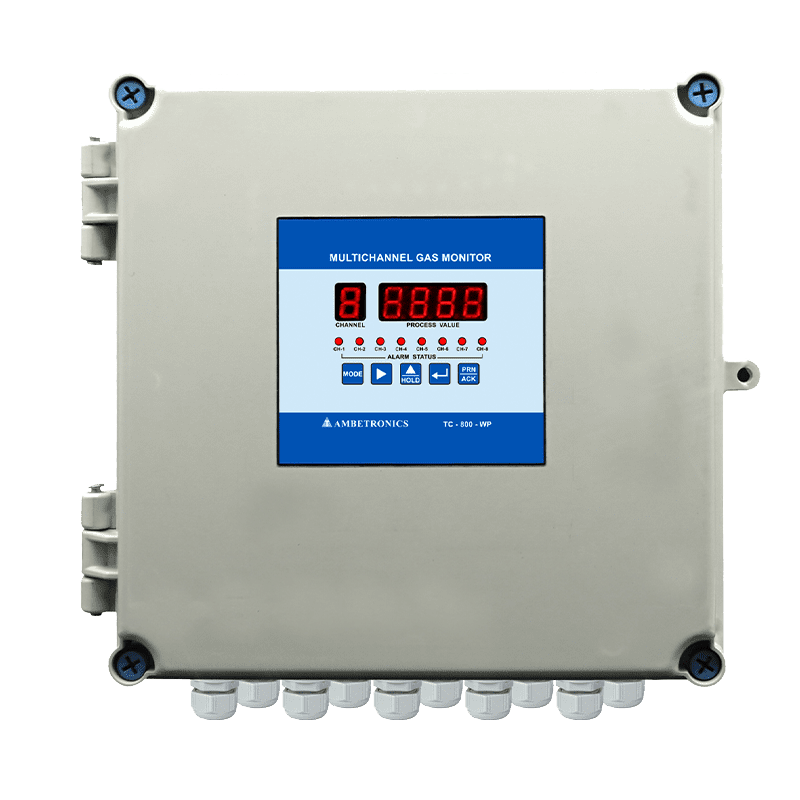

Multichannel Gas Monitoring System | TC-800-WP

The TC-800-WP Multichannel Gas Monitoring System is a state-of-the-art solution designed for comprehensive gas monitoring in various industrial environments. With user-friendly operation through front keys, this system offers the flexibility to scan each channel for gas concentration in PPM, PPB, or %V/V, ensuring accurate and reliable measurements. Equipped with features like easy one-man calibration at the site, open-loop transmitter sensor break indication, and individual channel skip and hold capabilities, the system provides efficient control and monitoring. It also includes a reading offset facility to compensate for field errors and high/low alarm outputs with programmable latch and non-latch options for common relay and relay indication. Ideal for applications in pulp and paper plants, chemical processing facilities, refineries, automotive industries, and more, this system can be customized with optional features such as data logging, and PC software. It supports up to 8 channels with a range of 0 to 9999, programmable by the user, and ensures a high level of measurement accuracy (±0.5% of the full-scale value).

1. User-Friendly Operation:

– In Multichannel Gas Monitoring System front keys enable easy and intuitive operation, facilitating user interaction with the monitoring system.

2. Multichannel Gas Monitoring:

– Multichannel Gas Monitoring System is capable of monitoring up to 8 channels simultaneously, providing comprehensive coverage in industrial settings.

3. Gas Concentration Readings:

– Displays gas concentration in PPM, PPB, or %V/V, offering flexibility in measuring different gas types.

4. One-Man Calibration:

– Simplifies calibration procedures, allowing a single operator to perform calibration on-site efficiently.

5. Open Loop Transmitter Sensor Break Indication:

– Alerts users to sensor break issues with a clear ‘OPEN’ indication, ensuring continuous monitoring reliability.

6. Individual Channel Control:

– Enables individual channel skip and hold functions from the front panel for customized monitoring configurations.

7. Reading Offset Facility:

– Multichannel Gas Monitoring System allows compensation for field errors through a reading offset facility, ensuring accurate gas concentration measurements.

8. High & Low Alarm Outputs:

– Provides high and low alarm outputs with programmable latch and non-latch options for common relay and relay indication.

9. Optional Features:

– Customizable with optional data logging, printer interface, and PC software for enhanced functionality.

10. Range and Resolution Programmability:

– User-programmable range (0 to 9999) and resolution (0.01, 0.1, 1) for flexibility in monitoring different gas concentrations.

11. Electrical Specifications:

– Accepts 4 to 20mA output from Oxygen/Toxic/Combustible Gas Transmitters, supporting 2-wire/3-wire configurations.

12. Error Monitoring:

– 4-digit LED display for process value indication and 1-digit LED display for channel number indication, aiding error detection.

13. Environmental Compatibility:

– Operates in temperatures from 0 to 50°C with a relative humidity below 95%, ensuring reliable performance in varied conditions.

14. Weatherproof Housing:

– IP65 protection in an ABS plastic enclosure with thermoplastic cable gland for cable entry, providing durability in challenging environments.

15. Mounting Options:

– Wall or stand mounting options with dimensions of 368 mm (H) x 290 mm (W) x 112 mm (D), making installation versatile.

16. Weight and Portability:

– Weighs approximately 2.5 kg, offering a lightweight and portable solution for gas monitoring needs.

17. Optional Accessories:

– Various optional accessories like CE-certified power supplies, gas calibration kits, hooters, flashers, and intelligent modems to enhance system capabilities.

| Pulp & Paper Plants | Automotive Industries |

| Chemical & Petrochemical Plants | Hotel Industries |

| Acid Alkalies & Dyes Manufacturing Plants | Gas Cylinder Banks |

| Chemical Processing Plant | Burner and Furnace Areas |

| Offshore Drilling & Processing Platforms | Heat Treatment Plants |

| Refineries | Paint Shops |

| Stack Monitoring | Sewage Plants |

| Chemical Storage Area | Fertilizer Plants |

| Power & Industrial Plants | Gas Metering Stations |

| Bullet Yards and Storage Yards | Oil and Gas Industries |

| Coal Mines and Confined Areas | Gas Pipeline Projects |