Our Standard Certifications

Single Gas Alert Monitor GM-1100 Series

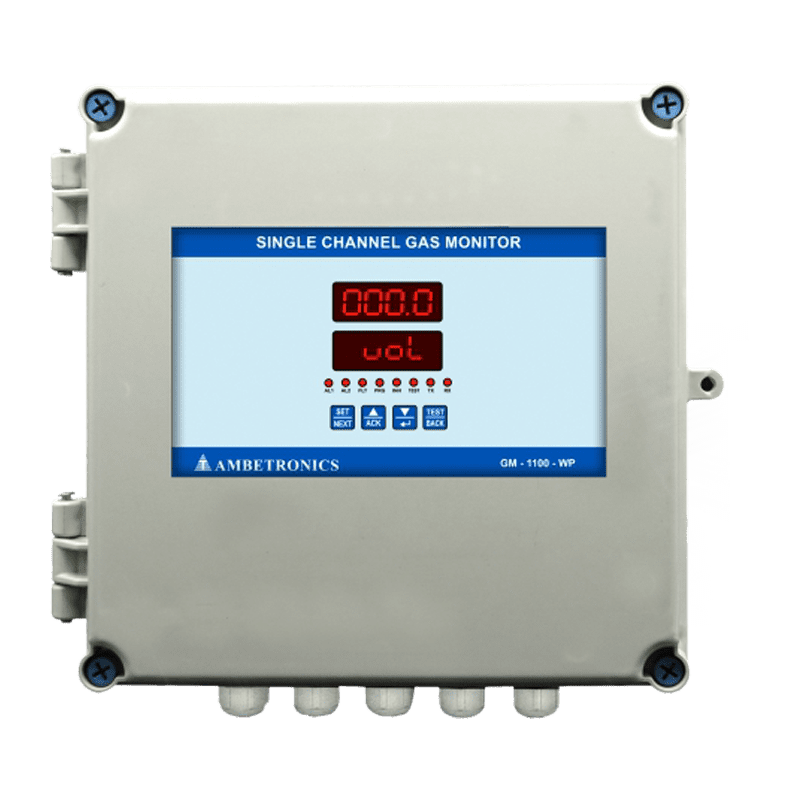

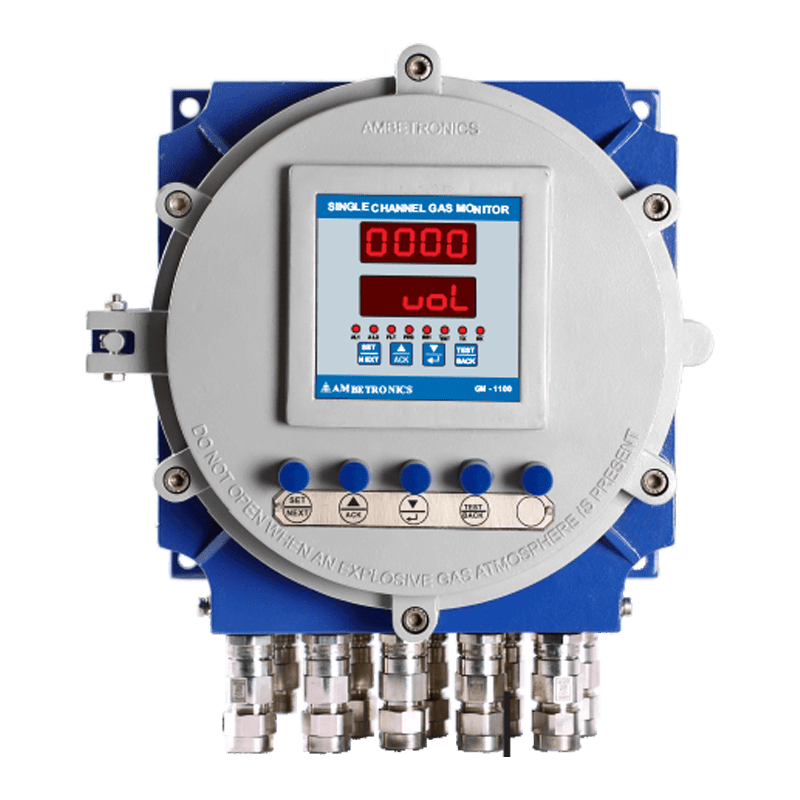

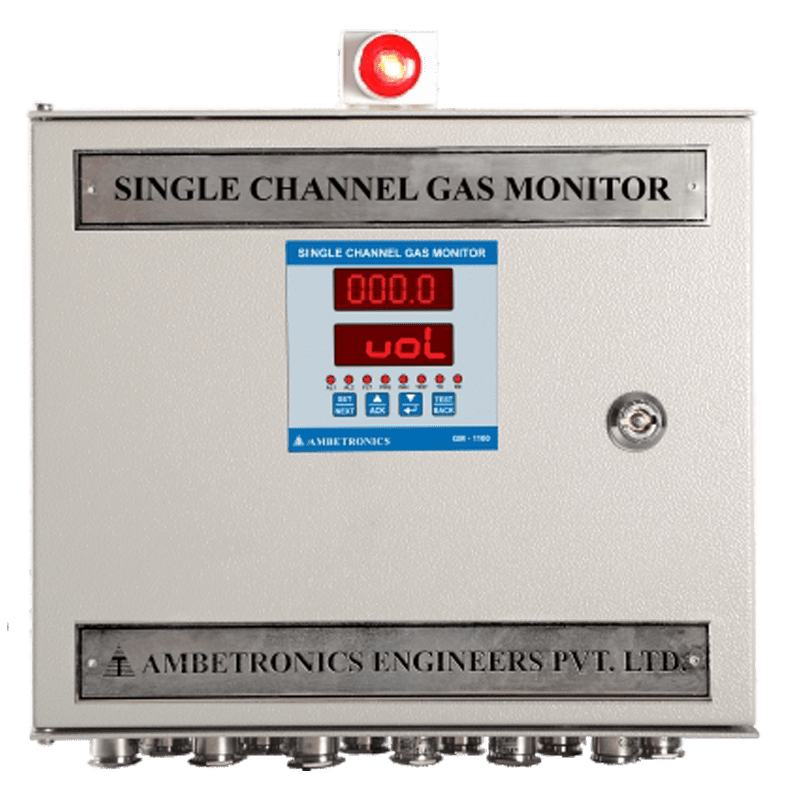

The GM-1100 Series Single Gas Alert Monitor is a cutting-edge solution for monitoring gas concentrations in various industrial environments. With dual displays providing real-time information on gas concentration and unit values, this microcontroller-based monitor offers accurate and reliable performance, minimizing false alarms. Featuring advanced warning and alarm outputs, the GM-1100 Series ensures a prompt response to potential hazards. The audio-visual alarm indication, along with two independent alarm relay outputs, enhances safety measures. Users have the option for easy one-man calibration at the site, and the device supports optional programmable linear 4-20mA output and RS-485 with Modbus RTU Protocol. Designed for diverse applications, including oil and gas industries, chemical plants, refineries, and more, the GM-1100 Series is suitable for hazardous areas with approvals from CCOE, CMRI, and IP-65. The user-friendly operation, password-protected programming, and various control actions make it adaptable to different industrial settings.

1. Dual Display: Single Channel Gas Alert Monitor provides simultaneous indication of gas concentration and unit values for enhanced monitoring.

2. Microcontroller-Based Technology: Single Channel Gas Alert Monitor utilizes the latest, accurate, and reliable technology, eliminating false alarms and ensuring high performance.

3. Advance Warning and Alarm Output: Prompts timely response to potential hazards, enhancing overall safety measures.

4. Audio-Visual Alarm Indication: Offers both audible and visual alerts for immediate awareness of gas concentration deviations.

5. Two Independent Alarm Relay Outputs: Allows customization with independent set points and programmable latch/non-latch functionality for each relay.

6. Optional Programmable Linear 4-20mA Output: Provides flexibility in output configuration based on gas concentration levels.

7. Optional RS-485 with Modbus RTU Protocol: Supports communication protocol for advanced connectivity and data exchange.

8. Easy One-Man Calibration: Simplifies calibration processes, allowing quick and efficient calibration on-site.

9. Hazardous Area Approval: CCOE, CMRI, and IP-65 approved, ensuring suitability for use in hazardous industrial environments.

10. User-Friendly Operation: Intuitive design and controls make operation straightforward for users.

11. Password Protected Programming: Enhances security by allowing only authorized personnel to access and modify programming settings.

Technical Specifications:

1. Input:

– Accepts 4 to 20mA output from Oxygen, Toxic, or Combustible Gas Transmitters.

2. Range:

– Programmable range from 0 to 9999 in units of P.P.M., % L.E.L., or % VOL.

3. Resolution:

– User-programmable resolution of 1 or 0.01.

4. Accuracy:

– ±1% of full-scale value.

5. Dual Display:

– Upper display shows 4 digits of 13mm (H) Red LED for Gas Concentration.

– Lower display shows 4 digits of 13mm (H) Red LED for Unit of Gas.

6. LED Indication:

– Provides indication for various states, including alarm relay status, programming mode, service/inhibit mode, test mode, and signal transmission/reception.

7. Set Point:

– Two independent set points for Alarm Relay-1 and Alarm Relay-2 with programmable latch and non-latch facility.

8. Control Action:

– Offers various control actions such as LO/HI, HI/LO, LO/Very LO, HI/Very HI, programmable by the user.

9. Hysteresis:

– Individual setting for Alarm Relay-1 and Alarm Relay-2, programmable by the user.

10. Time Delay:

– Independent programmable time delay from 0 to 9999 seconds for Alarm Relay-1 and Alarm Relay-2.

11. Relay Output:

– Three relay outputs (1 NO-C-NC) for Alarm Relay-1, Alarm Relay-2, and Fail-Safe Relay.

12. Electrical:

– Supports power supply options of 23VAC ± 10%, 110VAC ± 10%, or 24VDC.

13. Environmental:

– Operating Temperature: 0 to 50°C ± 5%.

– Relative Humidity: Below 95% non-condensing.

14. Housing:

– Weatherproof housing in IP-65 protection class, made of ABS plastic.

– Flameproof housing in IP-66 protection class, with cast Aluminum Lm6 Alloy Enclosure.

– MS Panel housing in IP-50 protection class, constructed with metal sheet in Siemens Grey color.

15. Dimensions and Weight:

– Weatherproof Housing: 317mm (H) x 365mm (W) x 160mm (D), Approx 2.5 Kg.

– Flameproof Housing: 357mm (H) x 316mm (W) x 182mm (D), Approx 12 Kg.

– MS Panel Housing: 300mm (H) x 320mm (W) x 105mm (D), Approx 6 Kg.

| Sewage Plants | Fertilizer Plants |

| Power and Industrial Plants | Gas Metering Stations |

| Bullet Yards and Storage Yards | Coal Mines and Confined Areas |

| Gas Pipeline Projects | Gas Cylinder Banks |

| Heat Treatment Plants | Automotive Industries and Paint Shops |

| Burner and Furnace Areas | Oil and Gas Industries |

| Chemical and Petrochemical Plants | Chemical Processing Plants |

| Pulp and Paper Plants | Acid Alkalies and Dyes Manufacturing Plants |

| Offshore Drilling and Processing Platforms | Refineries |

| Stack Monitoring | Chemical Storage Areas |

| Ambient Monitoring |