Our Standard Certifications

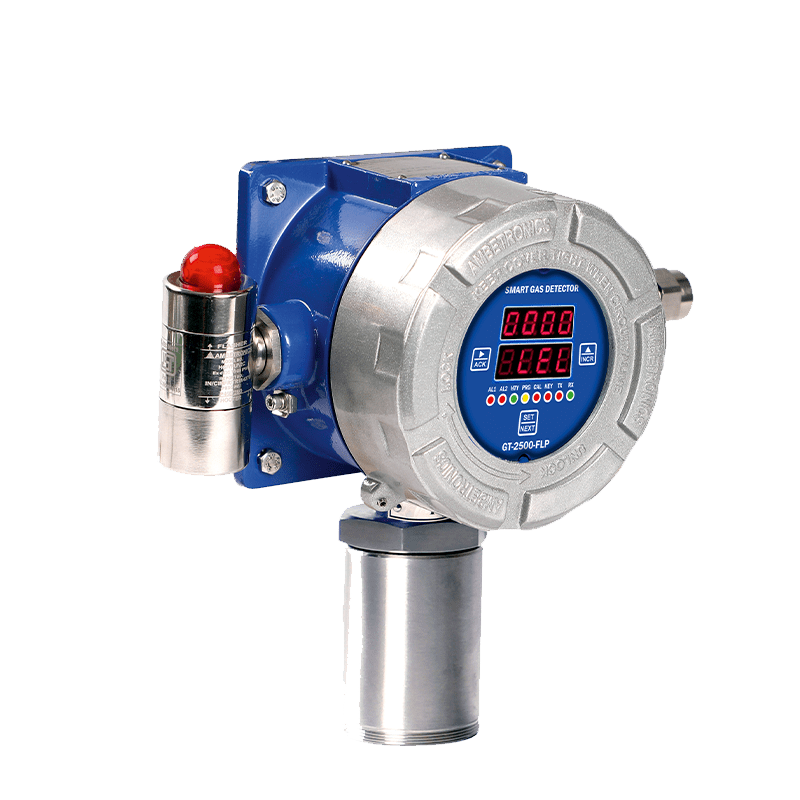

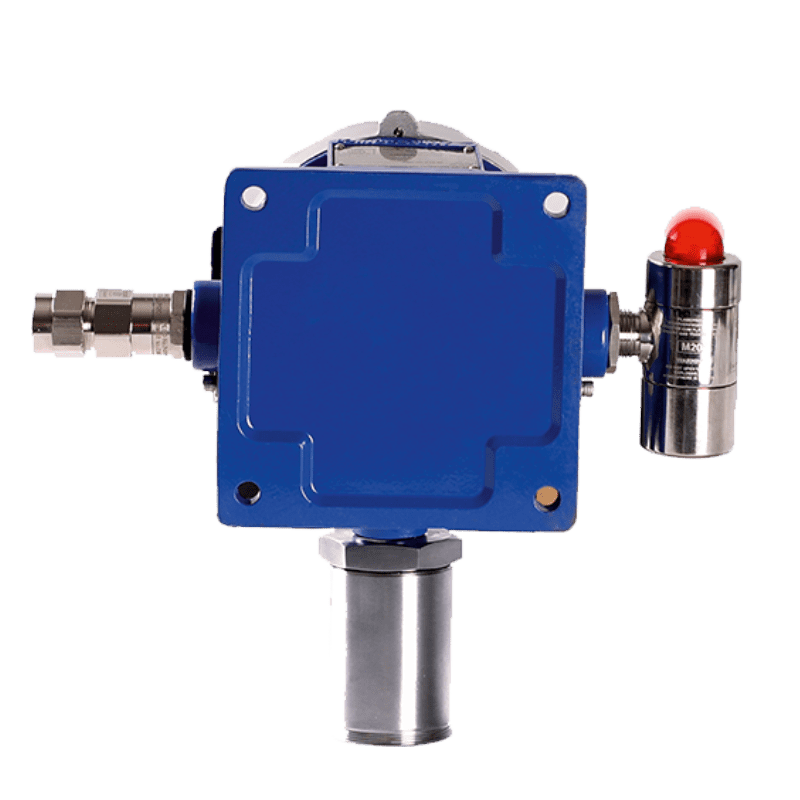

Smart Gas Detector with LED Display – GT-2500-FLP

The GT-2500-FLP, a PESO certified Flameproof Smart Gas Detector/Transmitter, stands as a robust solution for the swift and dependable detection of Oxygen, Toxic, Combustible, and Volatile Organic Compounds (VOC) gas leaks. Its user-friendly design includes a 7-Segment LED display for digital gas concentration readouts and 8 LEDs providing clear indications of the instrument’s status. With a standard 4-20mA signal output and three relay outputs, each with a 5A rating for both AC and DC, it ensures seamless integration into monitoring systems. The optional Isolated RS-485 Communication Port with MODBUS RTU PROTOCOL enhances connectivity. The device boasts a hot-swappable gas sensor module, allowing for easy maintenance and servicing, and features non-intrusive programming for the Flameproof Model using a Magnetic Wand. Recognizing its versatility, it can detect gas concentrations down to PPM, %V/V, %LEL, and mg/m³, with indications for various conditions such as ‘Sensor Open,’ ‘Over Range,’ ‘Sensor Replace,’ ‘Cal Due,’ ‘Cal Fail,’ and ‘mA Loop Open.’ This comprehensive set of features positions the GT-2500-FLP as a reliable and efficient gas detection solution for diverse industrial applications.

1. Versatile Gas Detection: Gas Detector Detects the smallest leaks of Oxygen, Toxic, Combustible, and Volatile Organic Compounds (VOC).

2. Modular Design: Smart, pluggable gas sensor module for easy replacement and maintenance.

3. Data Storage: Calibration, alarm, offset, and output current data saved in the sensor module for efficient maintenance.

4. Poisoning Resistance: Gas Detector is Highly resistant to poisoning and etching for prolonged sensor life.

5. Detection Range: Capable of detecting down to PPM, %V/V, %LEL, mg/m3.

6. Display and Indicators: 2-Line, 4-Digit LED display with 8 LEDs indicating instrument status.

7. Alarm Indications: Alerts for ‘Sensor Open’, ‘Over Range’, ‘Sensor Replace’, ‘Cal Due’, ‘Cal Fail’, mA Loop Open.

8. Output Signals: Standard 4-20mA signal output with configurable range.

9. Optional Set Points: Configurable STEL and TWA set points for Toxic & VOC Gases.

10. Communication Options: Optional RS-485 Communication Port with MODBUS RTU PROTOCOL.

11. Non-Intrusive Programming: Flameproof model programmable using a magnetic wand without opening the enclosure cover.

12. Security Features: Password-protected programming with password changing facility.

13. Alarm Acknowledgement: Facility for acknowledging alarms from the front as well as the rear terminal.

14. Test Mode: Allows checking electronics, alarm LEDs, relays, and output current/voltage with or without a sensor module.

15. Relay Contacts: Optional relay contacts on board with two configurable alarm levels and one fail-safe relay.

Technical Specifications:

1. Flameproof Approval: Ex db IIC T6 Gb IP 66/IP68.

2. Certifications: CIMFR and PESO certificates for flameproof enclosure.

3. Intrinsically Safe Approval: Ex d [ia] IIC T6 Ga Ex tb IIIC T85°C Db IP68.

4. Sensor Technology: Electrochemical/Catalytic/Pellistor/NDIR/PID/Solid State.

5. Detection Method: Diffusion.

6. Response Time: Less than 15 seconds (Depending on the type of gas).

7. Power Supply: 18 to 36 VDC, Typically 24VDC.

8. Power Consumption: Less than 3.6 Watts.

9. Operating Temperature: -15 to +55°C.

10. Storage Temperature: -10 to 60°C.

11. Humidity: Less than 95% Non-Condensing.

12. Dimensions (Without Hooter cum Flasher): 225 mm (H) x 225 mm (W) x 122 mm (D).

13. Weight (Without Hooter cum Flasher): Approx. 2.2 kg.

14. Optional Accessories: Power supply, canopy & mounting stand, gas calibration kit, hooter cum flasher, gas sampling system, communication converters.

15. Common Deliverables: Test calibration certificate, reference calibration gas certificate, operational/instrument user manual, standard mounting hardware.

| Refineries | Gas Cylinder Bank |

| Cold Storage | Oil & Gas Industries |

| Sewage Plants | Gas Pipeline Project |

| Fertilizers Plants | Pulp & Paper Plants |

| Stack Monitoring | Gas Metering Station |

| Chlorination Plant | Burner / Furnace Areas |

| Ambient Monitoring | Bullet Yard / Storage Yard |

| Gas Metering Skid | Chemical Processing Plant |

| Gas Cylinder Bank | Heat Treatment Plants |

| Oil & Gas Industries | Chemical Storage Area |

| Gas Pipeline Project | Control Atmosphere |

| Pulp & Paper Plants | Power & Industrial Plants |

| Gas Metering Station | Acid Alkalizes & Dyes Mfg. Plants |

| Burner / Furnace Areas | Offshore Drilling & Processing Platforms |

| Bullet Yard / Storage Yard | Coal Mine and Confined Area |

| Chemical Processing Plant | Chemical & Petrochemical Plants |

| Heat Treatment Plants | Automotive Industries / Paint Shops |