Our Standard Certifications

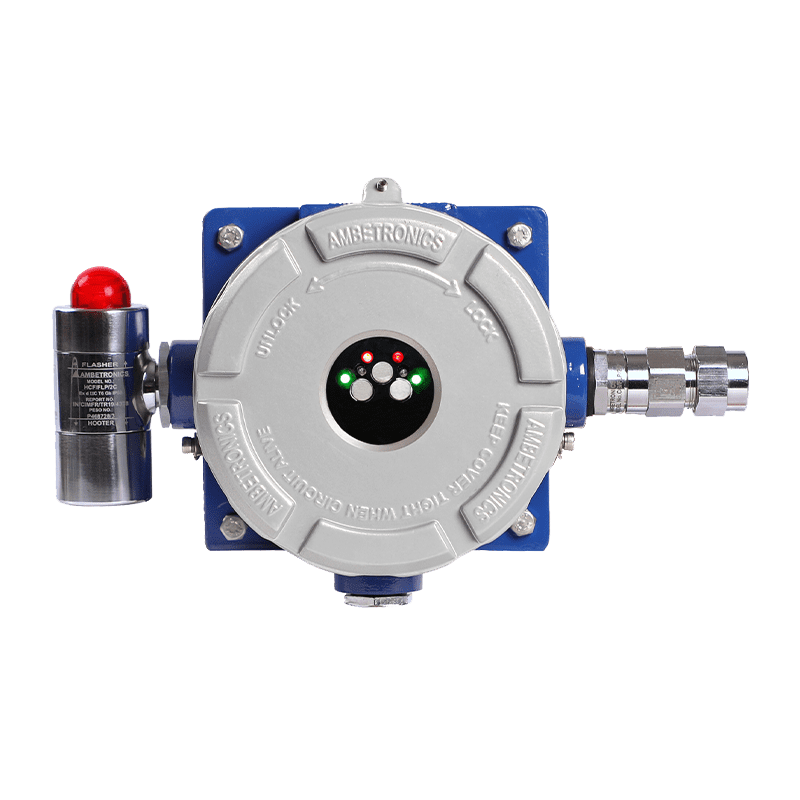

Triple IR Sensor Flame Detector – FLD-3300-FLP

The FLD-3300-FLP is a Triple IR Flame Detector designed for reliable and high-performance flame detection. Its triple-spectrum design ensures long-distance detection with high immunity to false alarms. The sensitivity selection feature prevents zone crossover detection, providing accurate and rapid flame detection. With a high dynamic range, it can detect both small and large flames over various distances. This flame detector offers multiple output options for flexibility, including three relays for flame detection, auxiliary, and fault signals, as well as 0-20mA or 0-10V output. It also supports optional features such as HART protocol for configuration, RS-485, and MODBUS compatibility. Users can conveniently configure the device through Bluetooth, HART, or RS-485. In terms of approvals and compliance, it meets flameproof standards (Ex d IIC T6 Gb, @ 60°C IP68) and adheres to relevant industry standards (IS/IEC 60079, IS/IEC 60529). It has approvals from CIMFR and PESO, ensuring its reliability and safety.

1. Triple Spectrum Design: Triple IR Sensor Flame Detector utilizes three infrared bands (3000 nm to 5000 nm) for long-distance flame detection with high immunity to false alarms.

2. Sensitivity Selection: Triple IR Sensor Flame Detector allows users to configure sensitivity settings to prevent zone crossover detection, ensuring accurate and reliable flame detection.

3. High Dynamic Range: Capable of detecting small and large flames, nearby or over large distances, providing versatile coverage.

4. Multiple Output Options: Offers flexibility with three relays for flame detection, auxiliary, and fault signals, along with 0-20mA or 0-10V stepped output options.

5. Optional HART Protocol: Provides an additional configuration setting option for users, enhancing compatibility.

6. User Programmable: Configuration settings can be easily adjusted via Bluetooth, HART, or RS-485, offering convenience and adaptability.

7. Built-in Self-Test (BIT): Features automatic self-check tests to ensure the proper functioning of the flame detector.

8. Mobile Alert (LoRa/WiFi): Optional feature for mobile connectivity and SMS alerts, enhancing real-time monitoring capabilities.

9. IoT Connectivity (Optional): Optional support for IoT connectivity, enabling integration with broader industrial systems.

10. Test Lamp Compatibility: Supports safe testing using a compatible test lamp for routine maintenance and functionality checks.

Technical Specifications:

1. Parameter Setting: Field configuration settings done via Bluetooth or MODBUS RTU Protocol.

2. Spectral Response: Three IR Bands – (3000 nm to 5000 nm).

3. Detection Range: Varies for different flammable substances, e.g., n-Heptane: 215ft, Kerosene: 150ft, Diesel Fuel: 150ft, Methanol: 116ft, Gasoline: 215ft.

4. Response Time: Typically less than 5 seconds, depending on flame size and sensitivity.

5. Field of View: 90° Horizontal, 90° Vertical.

6. Adjustable Time Delay: Up to 30 seconds.

7. Adjustable Sensitivity: Low, Medium, and High settings.

8. Power Supply: 18 to 36 VDC, typically 24VDC. Power consumption is less than 3W.

9. Output Signal: 4-20mA or 0-10V with LED indication for normal, fault, and fire detection.

10. Relay Outputs: Three SPDT relays for fail-safe, fire detection, and auxiliary output.

11. Communication Ports: RS-485 with MODBUS RTU protocol, optional HART protocol.

12. Environmental Operating Conditions: Operating temperature -15°C to +50°C, storage temperature -20°C to +85°C, humidity less than 95% non-condensing.

13. Flameproof Housing: IP66 & IP68 rated, available in Cast Aluminium LM6 alloy or Stainless Steel.

14. Optional Accessories: RS-485 to USB or RS-232 converter, hooter cum flasher, protection cover, heat detector, air shield, magnetic wand, and test lamp.

15. CIMFR & PESO Approvals: Compliance with relevant standards, approvals, and certifications for flameproof housing, cable glands, stopping plugs, and enclosures.

16. Dimensions and Weight: Vary based on the enclosure type, with options for wall or pipe mounting.

| Aircraft Hangars | Car, Bus, Tram, and Train Parking |

| Diesel Engine Rooms | Electric Power Transformers |

| Hydraulics (e.g., Extruders) | Paint Spray Booths |

| Wind Turbines | Compressor Stations |

| Chemical Sites | Storage Tanks |

| Spray Booths | Pharmaceutical Production |

| Printing |