Our Standard Certifications

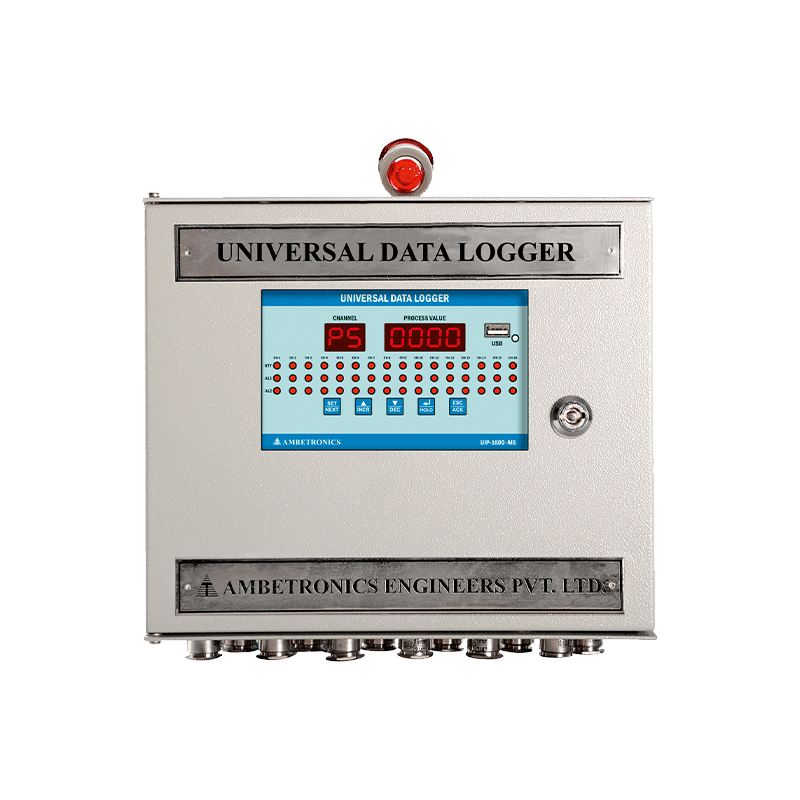

16 Channel Universal Data Logger | UIP-1600-MS

The UIP-1600-MS is a 16 Channel Universal Data Logger equipped with cutting-edge microcontroller technology, ensuring enhanced accuracy. It features 16 universal input channels supporting thermocouples (types J, K, R, S, T, B, N), RTD (PT-100), and 4-20mA programmable by the user, enabling versatile applications across various industries, including Fertilizer Plants, Oil & Gas, Refineries, Chemical Processing, and more.The device offers convenient on-line field calibration through a user-friendly membrane keypad on the front panel. Users can customize channel scan times, logging intervals, and printing intervals for efficient data monitoring. It includes a remote acknowledgement feature for relays, optional RS-485 Modbus serial port, and USB host for online/logged data reports via a Pen Drive.

- Advanced Microcontroller Technology: 16 Channel Universal Data Logger Utilizes the latest microcontroller-based technology to ensure superior accuracy in data scanning and logging.

- 16 Channel Input: 16 universal input channels supporting thermocouples (types J, K, R, S, T, B, N), RTD (PT-100), and 4-20mA programmable by the user.

- On-line Field Calibration: Easy calibration through a front panel membrane keypad, facilitating quick adjustments in the field.

- User-Programmable Scan Time: Field programmable channel scan time ranging from 1 to 240 seconds, allowing customization based on specific requirements.

- Remote Acknowledgement Facility: Enables remote acknowledgment for relays, enhancing control and monitoring capabilities.

- Optional Communication Ports: Offers optional RS-485 Modbus serial port, and USB host for online/logged data reports via a Pen Drive.

- External Relay Module: 16 Channel Universal Data Logger includes a separate external relay module for Alarm-1, Alarm-2, and Healthy indications, with individual relay outputs per channel.

- Dual Set Points with Latching: Provides two independent user-programmable set points for each channel, with user-settable latching for common relays.

- Error Monitoring: Monitors gas detector conditions, displaying ‘Break/Open’ as ‘oPEn’ and indicating under and over-range conditions as ‘Undr’ and ‘ouEr,’ respectively.

- Wide Operating Temperature Range: Functions efficiently in extreme temperatures, with an operating range from -40°C to 85°C.

Technical Specifications:

- Display: 4-digit LED display for process value indication, 2-digit LED display for channel number indication.

- Input: 16 universal input channels supporting thermocouples (types J, K, R, S, T, B, N), RTD (PT-100), and 4-20mA programmable by the user

- Accuracy: ± 0.25%.

- Control Action: Low/High control action for Alarm 1 – Low and Alarm 2 – High, user programmable.

- Setting: Configurable through a 5-key keypad on the front panel or push button keys for different models.

- LED Indication: 8/16 red LEDs for Alarm 1, Alarm 2, and Healthy indications, depending on the model.

- Supply Voltage: 90 to 270 VAC (50Hz) or 110 VDC to 270VDC.

- Frequency: 50Hz.

- Scan Time: Programmable between 1 to 240 seconds.

- Logging Interval: Programmable between -99 to 9999 seconds for data logger models.

- Environmental Protection: IP-50 rated MS Panel Housing with metal sheet Siemens Grey color.

- Cable Entry: Single Compression Gland.

- Dimensions: 275 mm (H) x 320 mm (W) x 100 mm (D) (without gland).

- Mounting: Wall Mounting/Stand Mounting.

- Weight: Approximately 6.1 Kg.

| Pharmaceutical Warehouse Monitoring | ISO Certification Record Keeping and Validation Processes |

| Online Profile Recording for Oven, BOD, Incubator, and Humidity Chamber | Pharmaceutical Warehouse Room Mapping |

| Blood Bank Monitoring | Pharmaceutical Process Validation with Graphs and Excel Reports for Autoclaves |

| Monitoring Winding Temperatures in Generators, Bearings, Motors, and Transformers | Heat Profile Monitoring in Furnaces and Foundries for Heat Treatment |

| Primary and Auxiliary Temperature Scanning of Boilers | Monitoring in Chemical and Hazardous Areas Where Data Monitoring is Crucial |