Our Standard Certifications

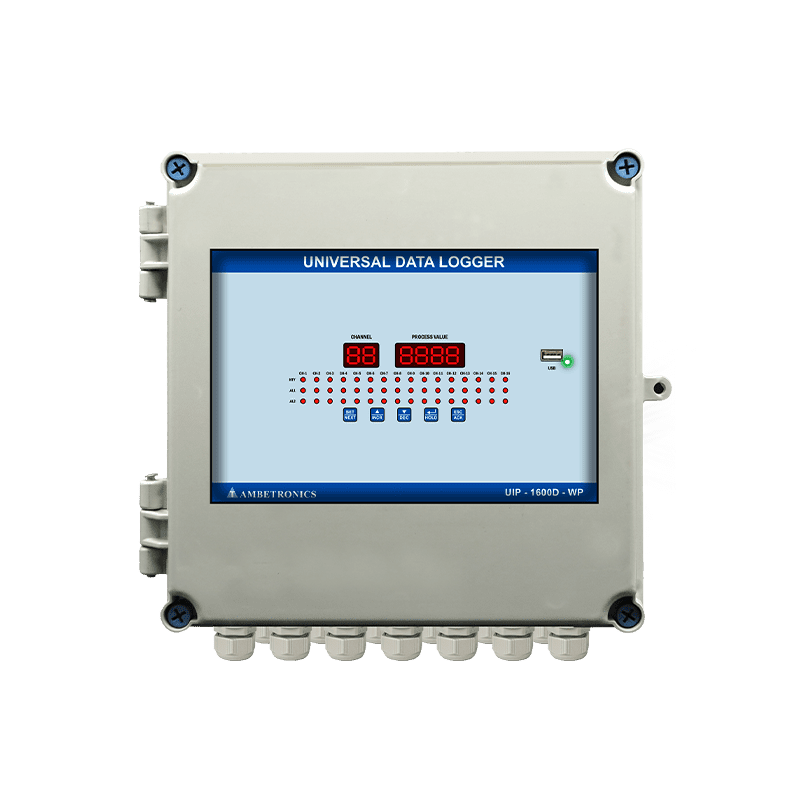

16 Channel Data Logger | UIP-1600-WP

The UIP-1600-WP 16 Channel Data Logger is a cutting-edge device employing the latest microcontroller technology to ensure superior accuracy in data monitoring and logging. 16 universal input channels supporting thermocouples (types J, K, R, S, T, B, N), RTD (PT-100), and 4-20mA programmable by the user, users benefit from easy on-line field calibration through the convenient front panel membrane keypad. The field programmable channel scan time and logging interval provide flexibility, catering to diverse industrial needs.

1. Cutting-Edge Technology: 16 Channel Data Logger utilizes the latest microcontroller technology for enhanced accuracy in data monitoring.

2. Versatile Input Channels: 16 universal input channels supporting thermocouples (types J, K, R, S, T, B, N), RTD (PT-100), and 4-20mA programmable by the user.

3. User-Friendly Calibration: Easy on-line field calibration facilitated by a front panel membrane keypad.

4. Flexible Programming: Field programmable channel scan time (1-240 sec) and logging interval (1-9999 sec) for adaptable performance.

5. Remote Acknowledgement: Offers remote acknowledgement facility for relays, providing convenient control.

6. Optional Connectivity: 16 Channel Data Logger features optional RS-485 Modbus serial port, and USB host for online/logged data reporting via a pen drive.

7. External Relay Module: Optional external relay module for Alarm-1, Alarm-2, and Healthy indications, with separate relay outputs per channel.

8. Control Action: Supports low/high control action for Alarm 1 – Low and Alarm 2 – High, programmable by the user.

9. Settable Parameters: User-settable latching for 4 common relays, with 2 independent user-programmable set points for each channel.

10. Error Monitoring: Monitors gas detector conditions, displaying ‘Break/Open,’ ‘oPEn,’ ‘Undr,’ and ‘ouEr’ indications for error conditions and input status.

Technical Specifications:

1. Input Type: 16 universal input channels supporting thermocouples (types J, K, R, S, T, B, N), RTD (PT-100), and 4-20mA programmable by the user.

2. Input Range: -99 – 9999

3. Accuracy: ± 0.25%

4. Control Action: Low/High control action for Alarm 1 and Alarm 2 (user programmable)

5. Supply Voltage: 90 to 270 VAC, 50Hz, or 110 VDC to 270VDC

6. Frequency: 50Hz

7. Scan Time: 1 to 240 sec (programmable by user)

8. Print Interval: 1 to 9999 sec for direct print out on 80 Column (Optional) EPSON LX-310 Dot Matrix Serial Printer

9. Logging Interval: 1 to 9999 sec for data logger model (Optional, programmable by user)

10. Logging Memory Capacity: Max. 8000 readings for all 16 channels.

11. Operating Temperature: -40°C to 85°C

12. Relative Humidity: Below 95%RH non-condensing

Environmental Details:

1. Protection Class: IP-65

2. Cabinet Material: ABS Plastic

3. Cable Entry: Thermoplastic cable gland (IP 65) with clamping range of 2.5 to 6.5 mm

4. Dimensions: 317 mm (H) x 365 mm (W) x 160 mm (D)

5. Mounting: Wall Mounting / Stand Mounting

6. Weight: Approx 2.5Kg

| Pharmaceutical Warehouse Monitoring | ISO Certification Record Keeping and Validation Processes |

| Online Profile Recording for Oven, BOD, Incubator, and Humidity Chamber | Pharmaceutical Warehouse Room Mapping |

| Blood Bank Monitoring | Pharmaceutical Process Validation with Graphs and Excel Reports for Autoclaves |

| Monitoring Winding Temperatures in Generators, Bearings, Motors, and Transformers | Heat Profile Monitoring in Furnaces and Foundries for Heat Treatment |

| Primary and Auxiliary Temperature Scanning of Boilers | Monitoring in Chemical and Hazardous Areas Where Data Monitoring is Crucial |