Our Standard Certifications

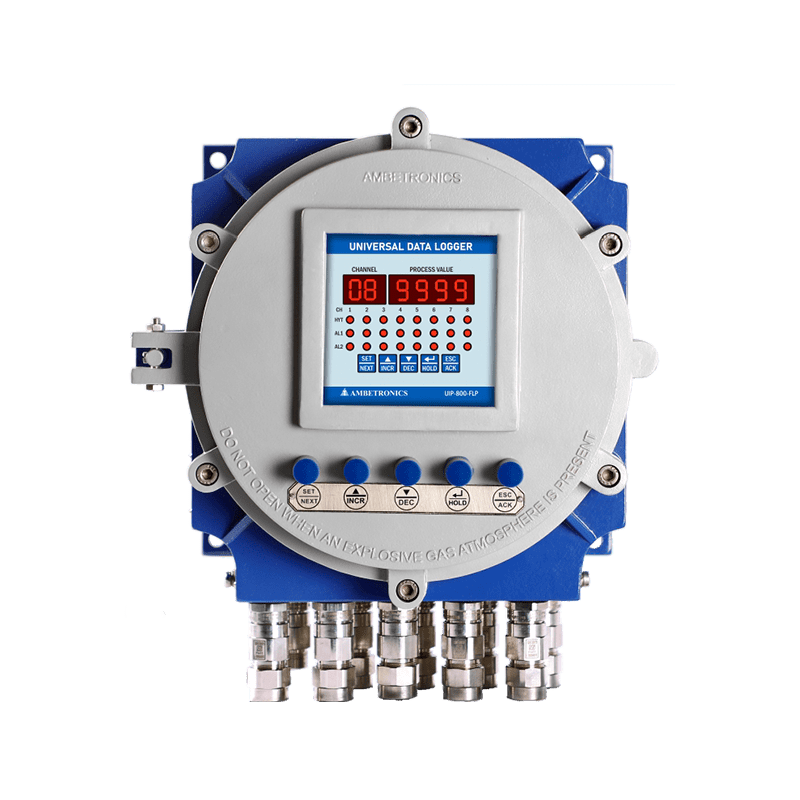

Universal Data Scanner/Logger | UIP-800-FLP

The UIP-800 -FLP is a state-of-the-art Universal Data Logger and Scanner designed for various industrial applications, including Fertilizer Plants, Oil & Gas Industries, Chemical Processing Plants, and more. Utilizing the latest microcontroller technology, it offers enhanced accuracy with 8 universal input channels supporting thermocouples (types J, K, R, S, T, B, N), RTD (PT-100), and 4-20mA programmable by the user. The device supports easy field calibration through a front panel membrane keypad and allows users to program channel scan times and logging intervals. Featuring optional RS-485 Modbus serial port, the UIP-800 -FLP provides flexibility in data reporting. It includes a separate external relay module for Alarm-1, Alarm-2, and Healthy indication, with individual relay outputs per channel. The device meets Flameproof certification standards (Ex d IIC T6 Gb, IP66) and complies with IS / IEC 60079-1, IS / IEC 60079-31, and IS / IEC 60529 standards.

1. Advanced Technology: Universal Data Logger Utilizes the latest microcontroller-based technology for enhanced accuracy in data logging and scanning applications.

2. Programmable Inputs: 8 universal input channels supporting thermocouples (types J, K, R, S, T, B, N), RTD (PT-100), and 4-20mA programmable by the user

3. Field Calibration: Easy on-line field calibration facilitated by a front panel membrane keypad ensures precise and convenient adjustments.

4. Flexible Scan Time: Field programmable channel scan time ranging from 1 to 240 seconds provides adaptability to different monitoring scenarios.

5. Versatile Logging Intervals: Logging interval customization from 1 to 9999 seconds accommodates various data recording needs.

6. Remote Acknowledgement: Remote acknowledgement facility for relays enhances control and monitoring capabilities.

7. Reliable Alarm System: Separate external relay module for Alarm-1, Alarm-2, and Healthy indication with individual relay outputs per channel ensures a robust alarm system.

8. Compliance Standards: Meets IS / IEC 60079-1, IS / IEC 60079-31, and IS / IEC 60529 standards, providing assurance of safety and regulatory compliance.

9. Flameproof Certification: Certified as Flameproof (Ex d IIC T6 Gb, IP66), making it suitable for use in hazardous environments.

Technical Specifications:

1. Display: 4-digit LED display for process value indication and 2-digit LED display for channel number indication.

2. Input Type: 8 universal input channels supporting thermocouples (types J, K, R, S, T, B, N), RTD (PT-100), and 4-20mA programmable by the user

3. Accuracy: ± 0.25% accuracy ensures reliable and precise data measurements.

4. Control Action: Offers low/high control action for Alarm 1 – Low & Alarm 2 – High, with user programmable settings.

5. LED Indication: 8 red LEDs for alarm 1, alarm 2, and Healthy indications for each of the 8 channels.

6. Set Point: 2 independent user programmable set points for each channel with 4 common relay outputs.

7. Relay Output: Relay output – NO/C/NC Relay Contact rated 5A/230VAC, with remote acknowledgement facility.

8. Monitoring of Error: Displays ‘oPEn’ for Gas Detector ‘Break/Open’ and indicates ‘Undr’ for under range and ‘ouEr’ for over range.

9. Scan Time: Programmable scan time between each channel, ranging from 1 to 240 seconds.

10. Operating Environment: Operates in a temperature range of -10°C to 60°C with below 95% RH non-condensing relative humidity.

11. Supply Voltage: Universal Data Logger supports a supply voltage of 90 to 270 VAC, 50Hz, or 110 VDC to 270VDC, with a frequency of 50Hz.

12. Flameproof Housing: IP-66 rated cast aluminum Lm6 alloy enclosure with double compression cable gland for secure cable entry.

13. Dimensions: Compact dimensions of 356 mm (H) x 316 mm (W) x 183 mm (D) for easy installation.

14. Mounting Options: Wall Mounting or Stand Mounting configurations available.

15. Weight: Approximately 12 Kg, ensuring a sturdy and durable build.

| Fertilizer Plants | Oil & Gas Industries |

| Chemical Storage Areas | Refineries |

| Offshore Drilling & Processing Platforms | Chemical Processing Plants |

| Gas Metering Stations | Bullet Yards / Storage Yards |

| Gas Pipeline Projects | Chemical & Petrochemical Plants |

| Power Industrial Plants | Hotel Industries |