Our Standard Certifications

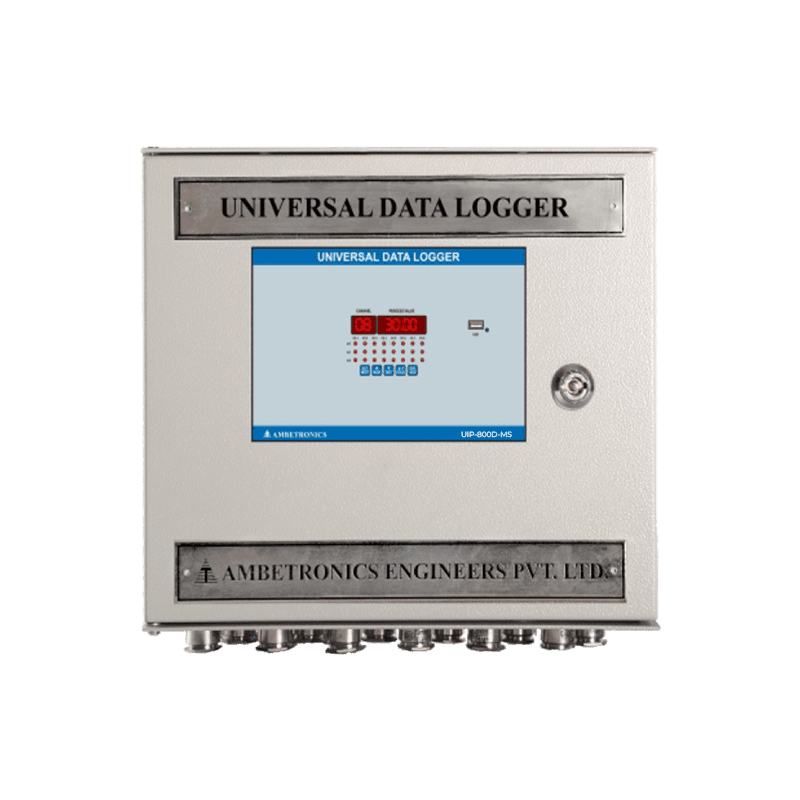

Universal Data Logger | UIP-800D-MS

The UIP-800D-MS Universal Data Logger is a cutting-edge device leveraging microcontroller-based technology for enhanced accuracy. Designed with versatility in mind, It offers enhanced accuracy with 8 universal input channels supporting thermocouples (types J, K, R, T, B, N), RTD (PT-100), catering to a variety of applications including fertilizer plants, oil and gas industries, refineries, and more. The logger facilitates easy on-site calibration through a user-friendly membrane keypad. With field-programmable options for channel scan time, logging interval, users can customize settings based on their specific needs. The device offers remote acknowledgement for relays, optional RS-485 Modbus serial port, and USB host connectivity for convenient online and logged data reporting via a pen drive.

1. Microcontroller Technology: Universal Data Logger utilizes the latest microcontroller-based technology for superior accuracy in data logging applications.

2. 8-Channel Input: Universal Data Logger offers enhanced accuracy with 8 universal input channels supporting thermocouples (types J, K, R, T, B, N), RTD (PT-100), offering flexibility for diverse industrial applications.

3. On-Site Calibration: Facilitates easy on-site calibration through a user-friendly front panel membrane keypad, ensuring precision in data collection.

4. Field-Programmable Settings:

– Channel Scan Time: User-adjustable between 1-240 seconds.

– Logging Interval: Programmable between 1-9999 seconds.

5. Remote Acknowledgement: Offers remote acknowledgement capability for relays, enhancing operational control and monitoring.

6. Optional Connectivity:

– RS-485 Modbus Serial Port: Optional serial port for communication using Modbus RTU protocol.

– USB Host: Optional connectivity for pen drives, enabling convenient online and logged data reporting.

7. Reliable Alarm System:

– Dual Set Points: Provides two independent user-programmable set points for each channel.

– Relay Outputs: Features relay outputs with user-settable latching for four common relays.

– Alarm Indications: 8 LEDs indicating alarm 1, alarm 2, and healthy status for each channel.

Technical Specifications:

1. Display:

– Process Value: 4-digit 13mm height Red LED 7-segment display.

– Channel Number: 2-digit 13mm height Red LED 7-segment display.

2. Input:

– Range: 0-9999.

– Accuracy: ± 0.25%.

– Control Action: Low/High control action for Alarm 1 (Low) & Alarm 2 (High) (user programmable).

3. Setting:

– Front Panel Keypad: Setting by 5 keys – ‘SET/NEXT’, ‘8/DECREMENT’, ‘ENTER/HOLD’, ‘ESC/ACK’.

– LED Indication: 8 RED LEDs for alarm 1, alarm 2, and healthy indications.

4. Relay Output:

– Type: NO/C/NC Relay Contacts rated at 5A/230VAC.

– Acknowledgement: Relay outputs with acknowledgment facility for relays.

5. Electrical:

– Supply Voltage: 90 to 270 VAC (50Hz) or 110 VDC to 270VDC.

– Frequency: 50Hz.

6. Environmental:

– Operating Temperature: -10°C to 60°C.

– Relative Humidity: Below 95% RH non-condensing.

7. Performance:

– Monitoring of Error: Displays ‘oPEn’ for ‘Break/Open’ and specific indications for under range and over range conditions.

– Scan Time: User-programmable scan time between each channel (1 to 240 seconds).

– Logging Intervals: User-programmable logging interval (1 to 9999 seconds).

8. Optional Features:

– Isolated RS-485-1 Serial Port: With MODBUS RTU protocol output.

– Isolated RS-485-2: For an external Alarm Relay Module.

– USB Host: Connectivity for online and log data reporting using a pen drive.

– Data Acquisition Software: Available for online graphs and historical data reports.

9. MS Panel Housing:

– Protection Class: IP-50.

– Cabinet Material: Metal sheet in Siemens Grey color.

– Cable Entry: Single Compression Gland.

– Dimensions: 275mm (H) x 320mm (W) x 100mm (D) (without gland).

– Mounting: Wall Mounting/Stand Mounting.

– Weight: Approximately 6.1 Kg.

| Fertilizer Plants | Oil & Gas Industries |

| Chemical Storage Areas | Refineries |

| Chemical Processing Plants | Offshore Drilling & Processing Platforms |

| Gas Metering Stations | Bullet Yards / Storage Yards |

| Gas Pipeline Projects | Chemical & Petrochemical Plants |

| Hotel Industries | Power Industrial Plants |