Safety Solution in Steel Industry

Safety in steel industries relies heavily on robust gas and flame detection systems to mitigate potential hazards. Our advanced detectors offer comprehensive monitoring and early warning capabilities against combustible gases, toxic substances, and fire risks, ensuring operational safety and regulatory compliance. By employing cutting-edge sensor technology, these systems provide reliable detection, swift response times, and flexible connectivity options, enhancing safety protocols and safeguarding personnel, assets, and the environment in steel industry operations.

In Furnace areas, ensuring safety and operational efficiency is paramount due to the risk of gas leaks. Without proper monitoring and detection systems in place, there's a heightened possibility of Combustible Gas, Oxygen Gas, Toxic Gas, Co Gas going undetected, posing serious threats to personnel and equipment. To address these concerns, installing a smart gas detector becomes imperative.

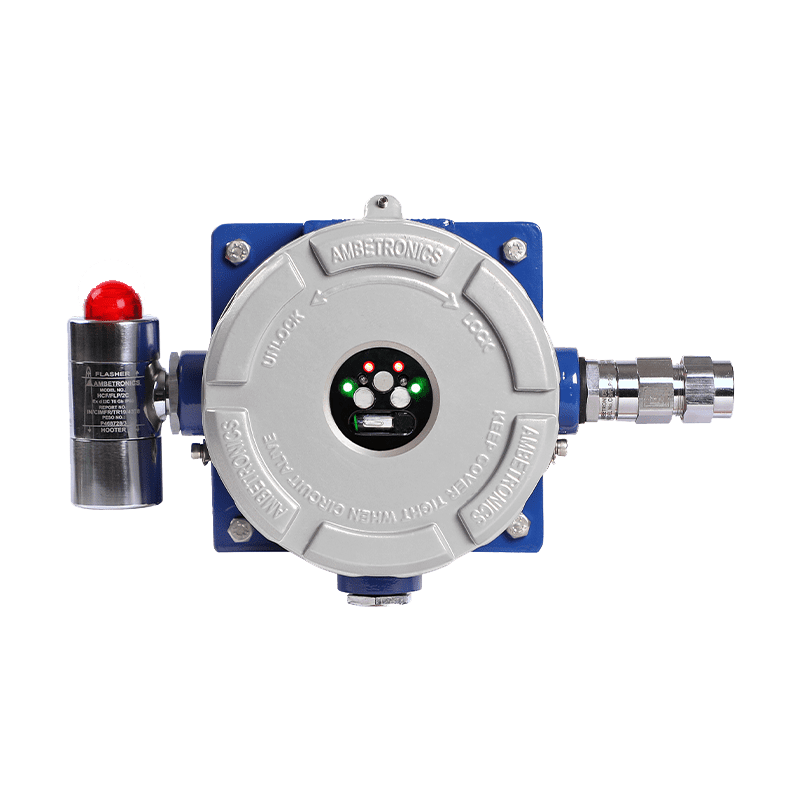

Smart Gas Detector – GT-2500-FLP

- Fast and Reliable Output: Detects the smallest leak of toxic and combustible gases.

- Enclosure: IP66/IP68 protection class for durability.

- Hot Swappable Smart Sensor: Allows on-site replacement if required.

- Automatic Calibration: Alerts for easy maintenance.

- Non-Intrusive Programming: Simplifies setup using a magnetic wand.

- RS-485 Communication Port: Optional communication protocol for compatibility.

In Coke Oven environments, the threat of gas leaks poses significant safety risks, necessitating robust detection systems. Without proper monitoring, even minor CO gas leaks can escalate into major hazards, endangering personnel and equipment. To address this critical need, the installation of a smart gas detector like the GT-2500-FLP is imperative.

Smart Gas Detector – GT-2500-FLP

- Fast and Reliable Output: Detects the smallest leak of toxic and combustible gases.

- Enclosure: IP66/IP68 protection class for durability.

- Hot Swappable Smart Sensor: Allows on-site replacement if required.

- Automatic Calibration: Alerts for easy maintenance.

- Non-Intrusive Programming: Simplifies setup using a magnetic wand.

- RS-485 Communication Port: Optional communication protocol for compatibility.

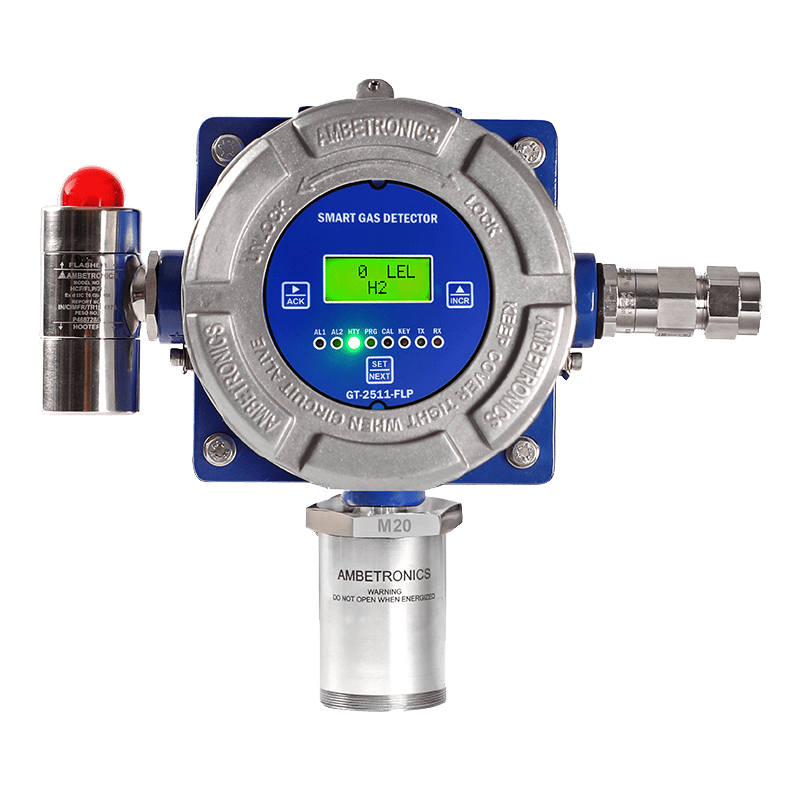

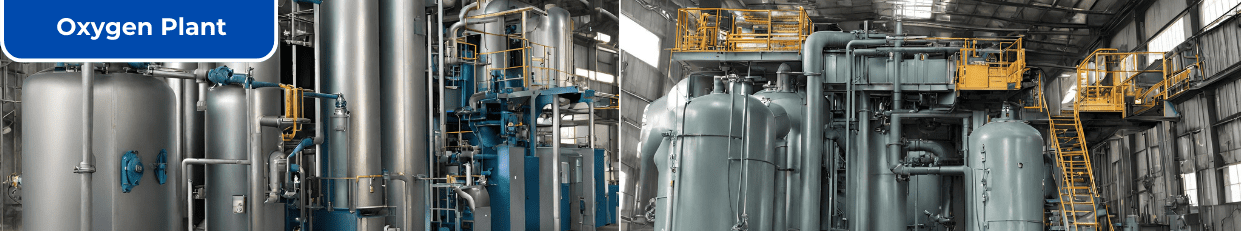

In Oxygen Plants, where precision and safety are critical, the threat of gas leaks demands proactive measures. Without effective monitoring, even minor leaks of oxygen can pose significant risks to personnel and operations. To mitigate these dangers, the installation of a reliable gas leak detector like the GT-2511-FLP is indispensable.

Smart Gas Detector – GT-2511-FLP

- Provides a fast reliable output for detection a smallest leak of Oxygen,

Toxic, Combustible and Volatile Organic Compounds (VOC). - Provision for smart – Pluggable gas sensor module for Oxygen, Toxic,

Combustible, PID & NDIR sensors. - Calibration data, Alarm data, Offset data, Output current data is saved in

the particular sensor module, for easy maintenance & servicing. - Highly resistant to poisoning and etching.

- Capable of detecting down to PPM, %V/V, %LEL, mg/m3.

- 2-Line, 4-Digit 8 mm (H) Seven Segment LCD Display & 8 LEDs to indicate

status of instrument

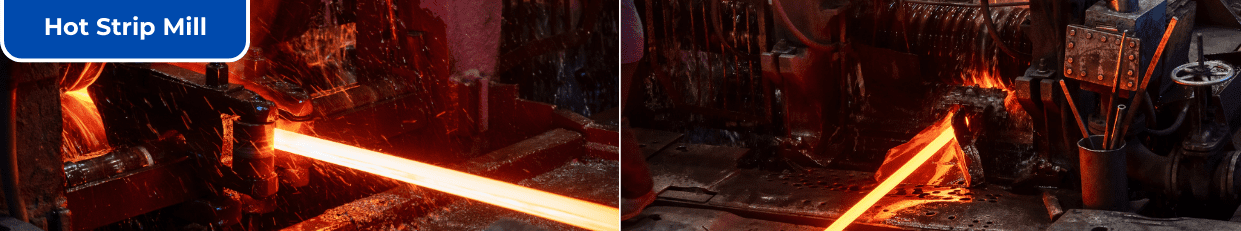

In HOT Strip Mills, the risk of fire is a constant concern due to high temperatures and combustible materials. Without adequate detection systems, such environments are susceptible to catastrophic events that endanger both personnel and infrastructure. To address these challenges, the installation of a critical component like the FLD-3311-FLP UV & Triple IR Sensor Flame Detector becomes imperative.

Flame Detector – FLD-3311-FLP

- Detector detects Multi-Spectral Sensitivity of fire by using UV & IR sensors.

- Clear Line of Sight visual range (upto specific distance).

- Triple Spectrum Design- For long distance detection & Excellent false alarm immunity.

- Sensitivity Selection – To ensure no zone cross

over detection. - High sensitivity combined with fast response time to

ensure rapid & accurate flame detection.

In Steel Painting and Coating Operations, safeguarding against hazardous gases is paramount to ensure worker safety and prevent accidents. Without proper monitoring, even minor VOC gas leak, HC Gas leak in service lines and joints can escalate into dangerous situations. To address this critical need, the installation of a vital tool like the PG-100-D Single Channel Portable Gas Detector becomes indispensable.

Single Channel Portable Gas Detector – PG-100-D

- The Plug-in Sensor provides a full year of warranted protection against hazardous gases.

- The Portable Detector detects smallest gas leak on service line and joints.

- Easy handling and programming with 3 keys and one key for power ON/OFF.

- Easy software calibration by using front keys.

- Digital display of Gas Concentration in %V/V or %LEL or PPM or PPB or µg/m or mg/m on LCD with backlight unit are adjustable by user setting.

- User settable Alarm 1 and Alarm 2 LCD display alert with 5 colors Red/Blue/Yellow/Cyan/Violet.

Effluent Treatment Plants (ETPs) and Sewage Treatment Plants (STPs) demand rigorous gas monitoring to ensure operational efficiency and safety. In such environments, the presence of volatile organic compounds (VOCs), and combustible gases poses significant risks. To address these concerns, the installation of a critical component like the GT-2500-WP Smart Gas Detector is essential.

Smart Gas Detector – GT-2511-FLP

- Fast Reliable Output: Detects the smallest leak of Gases like H2S, NH3, H2SO4.

- Enclosure: IP65 protection class.

- Hot Swappable Smart Sensor: Allows immediate on-site replacement.

- Automatic Calibration: Alerts for easy maintenance.

- RS-485 Communication Port: Optional for broader compatibility.

In Quenching Applications, ensuring safety against fires is paramount, given the high-risk environment and potential hazards involved. Without effective flame detection systems, the risk of accidents and damage to equipment escalates significantly. To mitigate these risks, the installation of a critical component like the FLD-3311-FLP UV & Triple IR Flame Detector becomes indispensable.

Flame Detector – FLD-3311-FLP

- Detector detects Multi-Spectral Sensitivity of fire by using UV & IR sensors.

- Clear Line of Sight visual range (upto specific distance).

- Triple Spectrum Design- For long distance detection & Excellent false alarm immunity.

- Sensitivity Selection – To ensure no zone cross

over detection. - High sensitivity combined with fast response time to

ensure rapid & accurate flame detection.

Enhancing Safety with Essential Accessories

Canopy

For Rain & Dust protection

Canopy Stainless Steel

For Rain & Dust protection

Transmitter Calibration Gases

• Canister • Fix Flow Regulator • Calibration Cap • PVC Pipe Hose

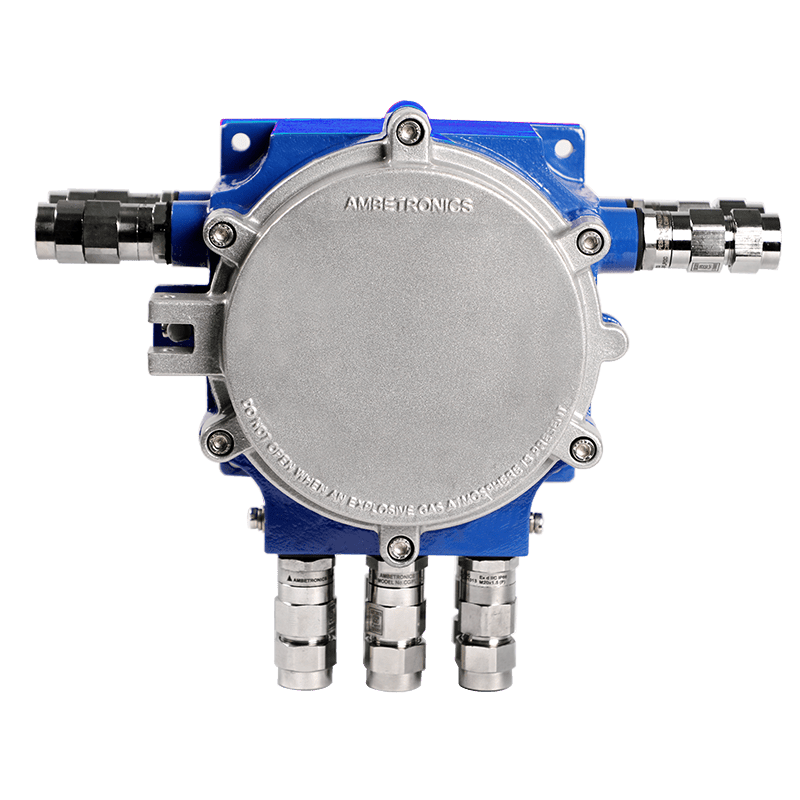

Flameproof Junction Box

• M20, ½” NPT • IP66 • Glands - 10 Max.

Flameproof Hooter Cum FLasher

• Red/Green/

Amber Flasher

• Sound level : 95/100 dB

•Stainless Steel 316/304

Flameproof Hooter Cum FLasher

• Red/Green/

Amber Flasher

• Sound level : 95/100 dB

•Stainless Steel 316/304