Our Standard Certifications

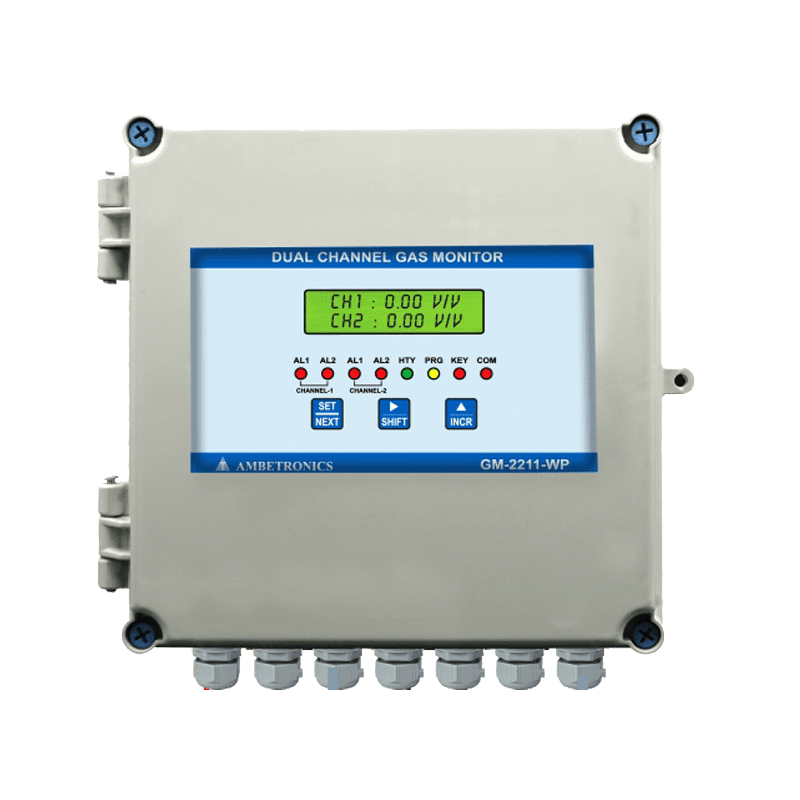

Dual Channel Gas Monitor GM-2211-WP

The GM-2211-WP Dual Channel Gas Monitoring System is a sophisticated and reliable solution designed for monitoring gas concentrations in industrial environments. With microcontroller-based technology, this system ensures the latest, accurate, and high-performance gas detection capabilities, minimizing false alarms. The unit features a clear 16 x 2 alphanumeric LCD/OLED display, providing gas concentration readings for two channels along with associated units and gas names. Equipped with advanced warning and alarm outputs, the system offers audio-visual indications, including two independent alarm relay outputs for each channel. Users benefit from easy handling and programming through a three-key interface, with optional remote control programming available up to 10 meters away. The programming menu is password-protected for security.

1. Dual Channel Monitoring: The Dual Channel Gas Monitoring System is equipped to monitor gas concentrations in two channels simultaneously, providing comprehensive coverage.

2. Microcontroller Technology: Dual Channel Gas Monitoring System utilizes advanced microcontroller-based technology for accurate and reliable gas detection, minimizing false alarms.

3. Clear Display: Features a 16 x 2 alphanumeric LCD/OLED display with auto-backlit option, offering easy visibility of gas concentrations, units, and gas names.

4. Advanced Warning and Alarm Outputs: Incorporates advanced warning systems and audio-visual alarms for immediate response to changing gas levels.

5. Dual Independent Alarm Relay Outputs: Provides two independent alarm relay outputs for each channel, enhancing flexibility in response actions.

6. Optional Voltage and Current Outputs: Offers optional programmable voltage and current outputs with configurable ranges for versatile integration into existing systems.

7. User-Friendly Interface: Easy handling and programming facilitated by a three-key interface on the front panel, with optional remote control programming up to 10 meters.

8. Password Protection: Ensures security with a password-protected programming menu, preventing unauthorized access.

9. Error Monitoring: Monitors sensor status and provides indications for sensor break, under-range, and over-range conditions for enhanced reliability.

Technical Specifications:

1. Input Compatibility: Accepts 2 channels of 4 to 20mA output from Oxygen/Toxic/Combustible Gas Transmitters.

2. Measurement Range: Programmable by the user, with a range from 0 to 9999 in PPM or % LEL or % V/V.

3. Response Time: Rapid response time of 500 milliseconds ensures timely detection of gas concentration changes.

4. Start-up Time: Quick start-up within approximately 30 seconds for prompt operation.

5. Power Supply: Wide power supply range of 90 to 270 VAC with low power consumption (less than 5 watts).

6. Output Signals: Standard relay outputs (120VAC/2A, 24VDC/2A) for failsafe and alarms, with optional isolated 0-20mA/4-20mA/0-5VDC/0-10VDC outputs.

7. Communication Port: Optional Isolated RS-485 communication port with Modbus RTU Protocol for enhanced connectivity.

8. Environmental Suitability: Operates in temperatures ranging from -15 to +55 degrees Celsius, with humidity levels below 95% non-condensing.

9. Weatherproof Housing: IP-65 rated weatherproof housing made of ABS plastic, suitable for diverse industrial environments.

10. Mounting Options: Flexible mounting options with wall or stand mounting capabilities.

11. Dimensions and Weight: Compact dimensions of 317 mm (H) x 365 mm (W) x 160 mm (D) and a weight of approximately 2.5 kg for easy installation.

| Refineries | Automotive Industries |

| Paint Shops | Oil and Gas Industries |

| Sewage Plants | Gas Metering Stations |

| Hotel Industries | Chemical Storage Areas |

| Fertilizer Plants | Burner and Furnace Areas |

| Stack Monitoring | Power and Industrial Plants |

| Gas Cylinder Banks | Bullet Yards and Storage Yards |

| Pulp & Paper Plants | Chemical Processing Plants |

| Gas Pipeline Projects | Coal Mines and Confined Areas |

| Heat Treatment Plants | Chemical & Petrochemical Plants |

| Automotive Industries | Acid Alkalies & Dyes Manufacturing Plants |

| Offshore Drilling & Processing Platforms |