Hydrogen Sulfide Gas Detector for Ensuring Safety in Industrial Environments

Before we explore the specifics of the Hydrogen Sulfide Gas Detector, it’s crucial to underscore the significance of safety in industrial settings. The well-being of employees, protection of assets, and compliance with regulatory standards are driving factors behind the adoption of advanced safety technologies.

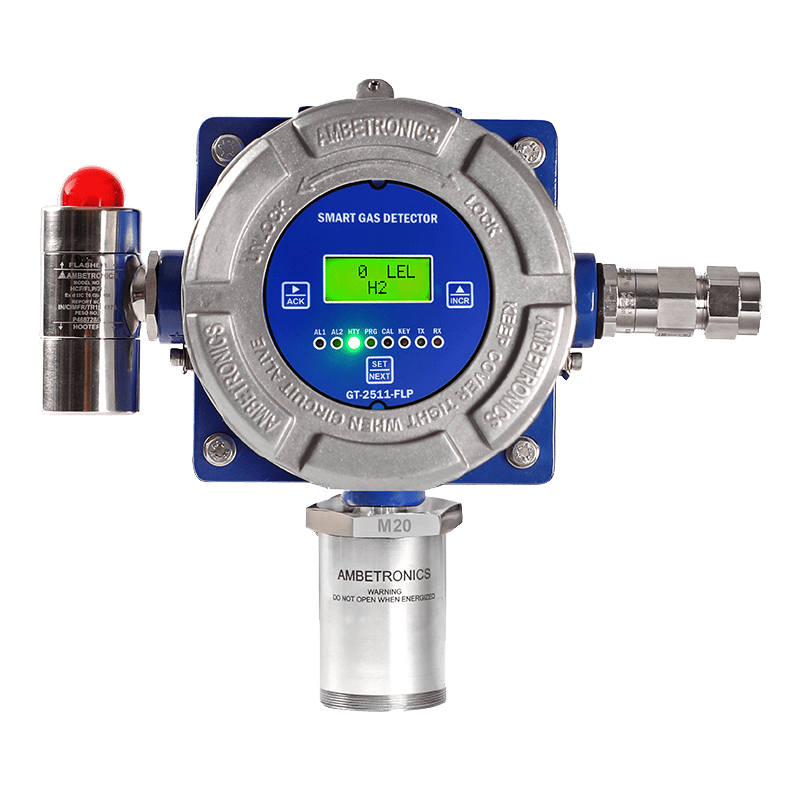

GT-2511-FLP

Smart Gas Detector - LCD Display

GT-2500-FLP

Smart Gas Detector - LED Display

GT-5022-FLP

Smart Gas Detector - Dual Channel

WGD-100-FLP

Battery Powered Wireless Gas Detector

GT-1033-FLP

2 Wired Loop Powered Gas Transmitter

Key Features of Ambetronics Hydrogen Sulfide Gas Detector

One standout feature is the provision for a smart, pluggable gas sensor module. Hydrogen Sulfide Gas Detector allows for the detection of various gases, including Oxygen, Toxic, Combustible, PID, and NDIR sensors. The calibration data, alarm data, offset data, and output current data are conveniently saved in the sensor module, facilitating easy maintenance.

Resistance to Poisoning and Etching

These detectors are highly resistant to poisoning and etching, ensuring their longevity in diverse industrial environments. Moreover, they are capable of detecting gases down to PPM, %V/V, %LEL, mg/m3, providing a wide range of applications.

Display and Indicators

The two-line, four-digit LED display and eight LEDs serve as crucial indicators, offering insights into the instrument's status. Indications for 'Sensor Open,' 'Over Range,' 'Sensor Replace,' 'Cal Due,' 'Cal Fail,' and mA Loop Open ensure that users are informed about the detector's condition at all times.

Additional Configurations

Optional Set Points and Communication Port For Toxic and VOC gases, optional STEL and TWA set points can be configured, enhancing flexibility. The inclusion of an optional RS-485 Communication Port with MODBUS RTU Protocol ensures seamless connectivity in industrial setups.

Non-Intrusive Programming

The non-intrusive programming for the Flameproof Model using a Magnetic Wand adds an extra layer of convenience. The password-protected programming with a password-changing facility enhances security.

Product Overview:

- Flameproof Enclosure Standards

The detectors comply with Ex db IIC T6 Gb IP 66 and Ex db IIC T6 Gb IP 68 standards for flameproof enclosures. Certificates from CIMFR and PESO authenticate their compliance.

- Smart Gas Detector/Transmitter Certifications:

For Smart Gas Detector/Transmitter, certifications include Ex db IIC T6 Gb Ex tb/tc IIIC T85°C Db/Dc IP68.

Applications:

Diverse Implementations: Hydrogen Sulfide Gas Detector find applications in a myriad of industries, from refineries and cold storage to sewage plants, gas pipeline projects, and automotive industries.

Ensuring Safety: In areas like control atmosphere, power plants, confined areas in coal mines, and chemical processing plants, Hydrogen Sulfide Gas Detector play a crucial role in maintaining safety standards.

Interested in our Hydrogen Sulfide gas detector system?

H2S Gas Detector Error Monitoring and Troubleshooting

The detectors provide detailed indications during sensor break/open, over-range situations, and output current open conditions. The 'Test Mode' allows users to check the electronics comprehensively.

Sensor Technology and Detection Methods

Various Sensor Technologies

With sensor technologies like electrochemical, catalytic, pellistor, NDIR, PID, and solid state, Hydrogen Sulfide Gas Detector employ diffusion as the detection method.

Gas Detected and Range/Resolution

The Hydrogen Sulfide Gas Detector can detect a range of gases, and users can select the range and resolution according to their specific needs.

Output Signal and Accuracy

Standard Current and Voltage Output

From refineries and cold storage to chemical processing plants and automotive industries, VOC gas detectors find applications in diverse industrial settings, ensuring a safer work environment.

Accuracy Levels

Different sensor technologies come with varying calibration accuracies, ensuring precision in detecting gases.

Common Deliverables and Performance

Essential Documents

Customers receive test calibration certificates, reference calibration gas certificates, operational manuals, and standard mounting hardware.

Performance

With an operating temperature range of -15 to +55 degrees Celsius and storage temperature ranging from -10 to 60 degrees Celsius, these detectors can withstand various environmental conditions.

Electrical and Environmental Considerations

Power Requirements

Operating on 18 to 36 VDC, typically 24VDC, the detectors consume less than 3.6 Watts, ensuring energy efficiency.

Environmental Suitability

Different sensor technologies come with varying calibration accuracies, ensuring precision in detecting gases.

Optional Accessories

Enhancing Functionality

Optional accessories like a CE-certified 24VDC power supply, canopy and mounting stand, gas calibration kit, hooter cum flasher, gas sampling, conditioning systems, and various connectivity options are available.

FAQs

How often should the gas detector be calibrated?

The frequency of calibration depends on usage, but a general recommendation is every six months to a year.

Can the detector be used in extreme temperatures?

Yes, the detectors are designed to operate in a wide temperature range, making them suitable for various environments.

Is the gas detector intrinsically safe?

Yes, the detectors hold certifications for being intrinsically safe, ensuring their safe operation in hazardous conditions.

What is the typical response time of the detector?

The response time is less than 15 seconds, ensuring a swift reaction to gas presence.

How do I acknowledge an alarm from the detector?

The alarm acknowledgment can be done from the front as well as the rear terminal.