Our Standard Certifications

Dual Channel Gas Monitor GM-2200 Series

The GM-2200 Series Dual Channel Gas Monitor is a cutting-edge solution for gas detection in various industrial environments. This advanced monitor features two independent displays for user-selected gas detectors, ensuring comprehensive monitoring. Utilizing microcontroller-based technology, it delivers accurate, reliable, and high-performance gas detection, minimizing false alarms. With a user-friendly design, the gas monitor offers easy one-man calibration at the site and provides long-term stability. The dual-channel display, featuring 2 x 4-digit LED screens, allows users to monitor gas concentrations for two different gases simultaneously. The monitor offers audiovisual indications for gas leakage, ensuring quick response and safety.

1. Dual Channel Display: Two independent displays for user-selected gas detectors, Dual Channel Gas Monitor allowing simultaneous monitoring of two gases.

2. Microcontroller Technology: Dual Channel Gas Monitor utilizes the latest microcontroller-based technology for accurate, reliable, and high-performance gas detection, minimizing false alarms.

3. Long-Term Stability: Ensures consistent performance over an extended period, enhancing reliability in gas detection applications.

4. Advance Warning & Alarm Output: Provides advanced warning signals and alarm outputs for quick response to potential gas leaks, contributing to enhanced safety.

5. Audiovisual Indication: Features audio and visual indicators for gas leakage, offering a quick and intuitive means of identifying potential hazards.

6. Easy One-Man Calibration: Facilitates straightforward calibration at the site by a single operator, ensuring ease of maintenance and operation.

7. Individual Alarm Relay Contacts: Offers separate alarm relay contacts for each channel, allowing precise control and response to specific gas concentrations.

8. Wall-Mounted Design: Designed for easy installation on walls, providing convenience and flexibility in positioning within industrial settings.

9. Hazardous Area Approval: Suitable for use in hazardous areas with approvals from CCOE, CMRI, and IP-65, ensuring compliance with safety standards.

10. Password-Protected Programming: Allows password-protected programming with the option to change passwords, enhancing security and preventing unauthorized access.

Technical Specifications:

1. Input:

– 2 x 4 to 20mA output from Oxygen/Toxic/Combustible Gas Transmitters (3-wire).

2. Range:

– Programmable by the user, ranging from 0 to 9999 in PPM or % LEL or % VOL.

3. Resolution:

– User-programmable resolution of 1 or 0.1, enhancing flexibility in monitoring.

4. Accuracy:

– ±1% of full-scale value, ensuring precise gas concentration readings.

5. Display:

– 2 x 4 digits of 13mm (H) Red LED display for Gas concentrations for CH-1 and CH-2.

6. LED Indication:

– 3mm, 7 LED indicators for AL1, AL2, TD1, TD2, PRG, TX, RX, providing visual cues for various states.

7. Set Point:

– Two common alarm setpoints for CH1 & CH2.

8. Control Action:

– LO/Very LO & HI/Very HI, programmable by user.

9. Hysteresis:

– Individual setting for Alarm Relay-1 & Alarm Relay-2, programmable by user.

10. Time Delay:

– Independent programmable 0 to 9999 seconds for Alarm Relay-1 & Alarm Relay-2.

11. Relay Output:

– Alarm Relay-1 & Alarm Relay-2 operate for CH-1 & CH-2.

12. Relay Contact Type:

– 1 NO/C/NC Relay contact rated 230VAC/5A each for Alarm Relay-1 & Alarm Relay-2.

13. Optional:

– Flameproof or Non-Flameproof Industrial Hooter, Hooter cum Flasher, Chart recorder, Cables, PC Software, Gas Transmitters, 24 VDC power supply, Gas calibration kit.

– Optional programmable linear 4-20mA output with respect to Gas concentration for CH-1 & CH-2.

14. Electrical:

– Power Supply: 230V AC ±10% or 110VAC ± 10% OR 24 VDC.

– Cable: 1.5 sq. mm 3-core OR 2-core, Flexible OR Armoured shielded cable from Gas Transmitter.

15. Error Monitoring:

– Sensor break/open shows ‘oPEn’, under range shows ‘Undr’, and over range shows ‘ouEr’.

16. Environmental:

– Operating Temperature: 0 to 50℃ ± 5%.

– Relative Humidity: Below 95% non-condensing.

17. Accessories (Optional):

– CE certified 24 VDC Power supply.

– 2/3 Core Cables for Transmission.

– Gas Calibration Kit (0.5, 1, 3, 10) Liter.

– Hooter cum Flasher.

– Annunciator Panel 4 Channel / 8 Channel.

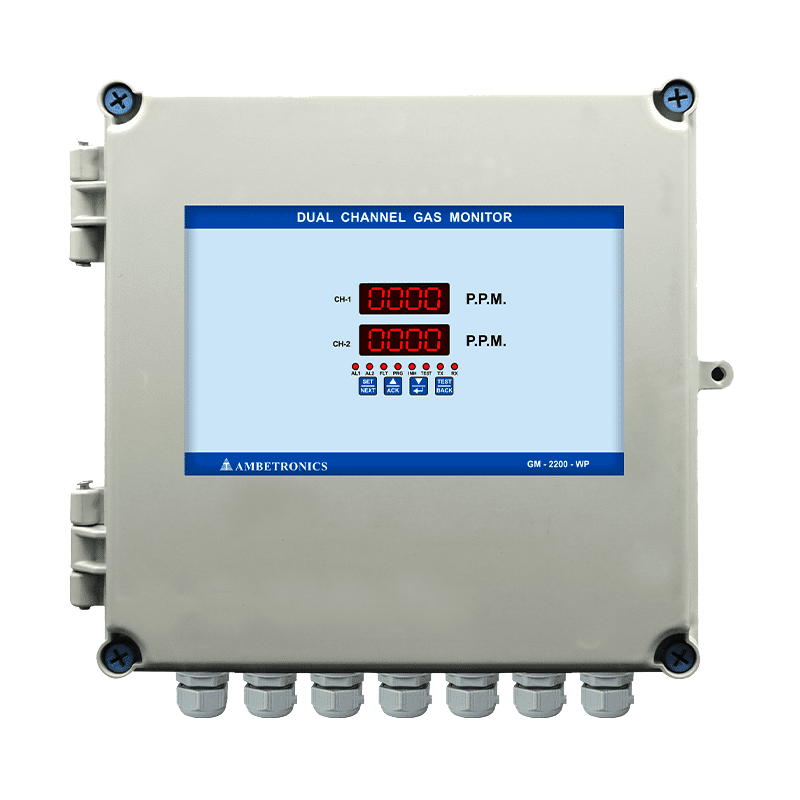

18. Weatherproof Housing Details:

– Protection Class: IP-65.

– Cabinet Material: ABS Plastic.

– Cable Entry: Thermoplastic cable gland (IP 65) with clamping range of 2.5 to 6.5 mm.

– Dimension: 317 mm (H) x 365 mm (W) x 160 mm (D).

– Mounting: Wall Mounting / Stand Mounting.

– Weight: Approx 2.5 Kg.

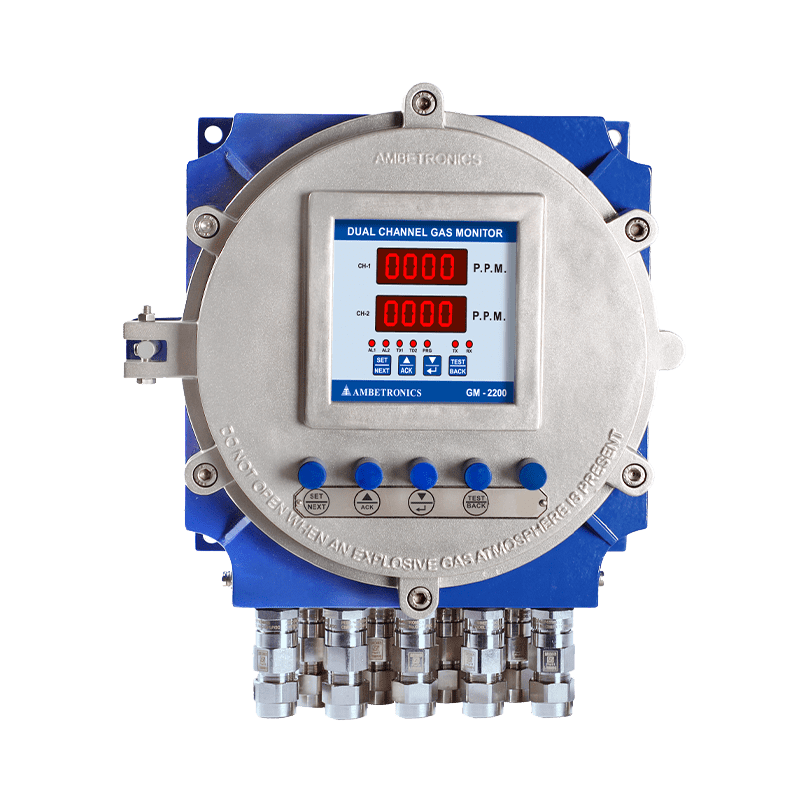

19. Flameproof Housing Details:

– Degree of Protection Class: IP-66.

– Housing Material: Cast Aluminum Lm6 Alloy Enclosure.

– Cable Entry: Flameproof, Weatherproof IP66 Double compression cable gland (E x d) Model No.: CG/FLP/2C M20 x 1.5 (P).

– Dimension: 357 mm (H) x 316 mm (W) x 182 mm (D).

– Mounting: Wall Mounting / Stand Mounting / Pipe Mounting.

– Weight: Approx 12 Kg.

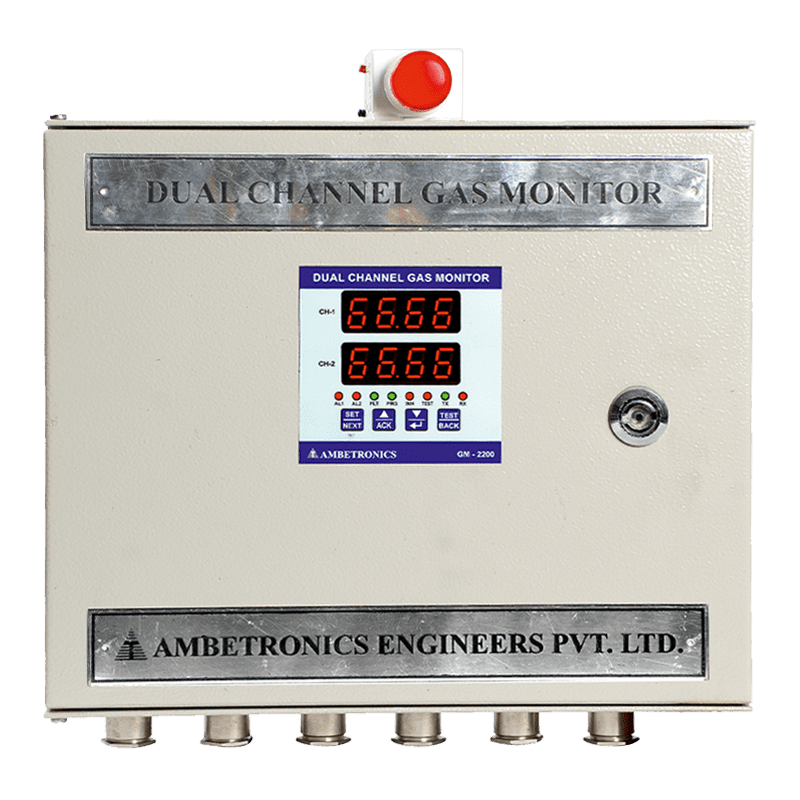

20. MS Panel Housing Details:

– Protection Class: Metal Sheet.

– Cabinet Material: Siemens Grey color.

– Cable Entry: Single Compression Gland.

– Dimension: 300 mm (H) x 320 mm (W) x 105 mm (D) (without gland).

– Mounting: Wall Mounting / Stand Mounting.

– Weight: Approx 6 Kg.

| Burner and Furnace Areas | Power and Industrial Plants |

| Heat Treatment Plants | Gas Metering Stations |

| Paint Shops | Bullet Yards and Storage Yards |

| Sewage Plants | Oil and Gas Industries |

| Fertilizer Plants | Coal Mines and Confined Areas |

| Gas Pipeline Projects | Pulp and Paper Plants |

| Chemical and Petrochemical Plants | Acid Alkalies and Dyes Manufacturing Plants |

| Chemical Processing Plants | Offshore Drilling and Processing Platforms |

| Refineries | Stack Monitoring |

| Chemical Storage Areas | Automotive Industries |

| Hotel Industries | Gas Cylinder Banks |