Our Standard Certifications

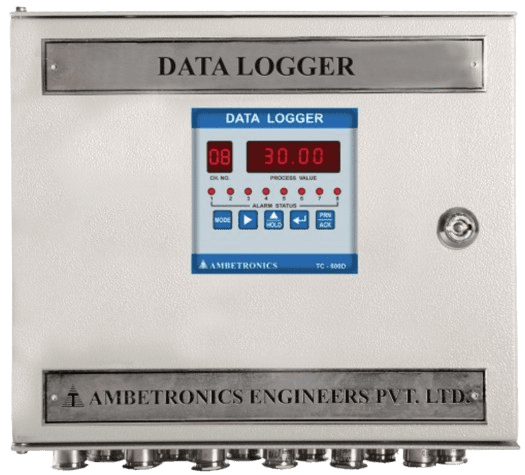

Multichannel Data Logger – TC-800D-MS

The TC-800D-MS Data Logger is a state-of-the-art device featuring the latest microcontroller technology for enhanced accuracy. It provides 8 fixed input channels supporting a variety of thermocouple types (J, K, R, S, T, E, B, N), RTD (PT-100), and either 4-20mA or 0-10 VDC., it offers unparalleled versatility. Users can easily calibrate on-site using the front panel membrane keypad, and field-programmable scan times and logging intervals cater to diverse application needs. This multichannel data logger includes optional RS-485/RS-232 Modbus Serial Port, automatic cold junction compensation for thermocouples, and temperature readings in both °C and °F. Its applications range from ISO certification records to pharmaceutical process validation, oven and BOD monitoring, generator winding temperatures, heat profiling in furnaces, and more.

1. Advanced Technology: Multichannel Data Logger utilizes the latest microcontroller-based technology for enhanced accuracy in data logging.

2. Multichannel Input: Multichannel Data Logger provides 8 fixed input channels supporting a variety of thermocouple types (J, K, R, S, T, E, B, N), RTD (PT-100), and either 4-20mA or 0-10 VDC.

3. On-site Calibration: Easy on-line field calibration facilitated by a front panel membrane keypad, ensuring precise measurements.

4. Flexible Programming: User-programmable channel scan time (1 to 59 sec) and logging interval (1 to 9999 sec) for tailored data collection.

5. Communication Options: Optional RS-485/RS-232 Modbus Serial Port for enhanced connectivity and communication capabilities.

6. Cold Junction Compensation: Automatic compensation for thermocouples’ cold junctions, ensuring accurate temperature readings.

7. Dual Temperature Units: Temperature readings available in both Celsius (°C) and Fahrenheit (°F), selectable by the user.

8. Applications Diversity: Suitable for a wide range of applications including ISO certification records, pharmaceutical process validation, oven and BOD monitoring, generator temperature monitoring, heat profiling in furnaces, and more.

Technical Specifications:

1. Display: 4-digit LED display for process value indication, 1-digit LED display for channel number indication.

2. LED Indication: 8 red LEDs for alarm indications (AL1 & AL2).

3. Set Points: 2 independent set points for each channel with 2 common relay outputs and programmable latch/non-latch facility.

4. Control Action: Programmable HI-LO, LO-Very LO, HI-Very HI control action logic.

5. Relay Outputs: 1 NO/C/NC Relay Contact (230VAC/5A) for each of the two common relays (AL1 & AL2).

6. Keypad Interface: 5 feather-touch keys for MODE, SHIFT, INC, ENT, PRN/ACK for panel & WP models, and push keys for Flameproof model.

7. Scan Time: Programmable scan/scroll time between each channel (0 to 59 sec).

8. Logging Interval: Programmable log interval for data logger model (1 to 9999 sec).

9. Memory: Data Logger model with a maximum capacity of 5193 readings for all 8 channels. Features memory saturation, memory scrolling (FIFO), and online PC interface.

10. Electrical:

– Supply Voltage: 100 to 270VAC.

– Frequency: 50Hz.

11. Environmental:

– Operating Temperature: -40 to 85°C.

– Relative Humidity: Below 95% RH (non-condensing).

12. Optional:

a) Isolated RS-485/RS-232 Serial Port with MODBUS RTU Protocol output.

b) SMARTLOG & Smart Pro Data Acquisition Software for online graphs & history data reports.

c) Individual Relay output or Grouping Relay output can be given for each channel.

13. MS Panel Housing:

– Cabinet Material: Metal Sheet Ivory Grey Color.

– Cable Entry: Single Compression Cable Gland.

– Dimension: 305mm(H) x 320mm(W) x 125mm(D).

– Mounting: Wall mounting/Stand mounting.

– Weight: Approx 4.5 kg.