Our Standard Certifications

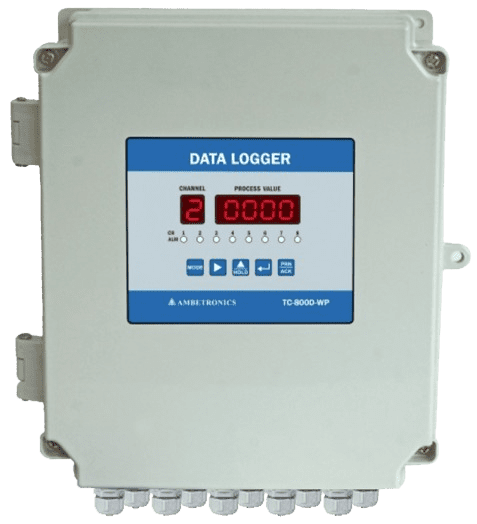

8 channel Data Logger | TC-800D-WP

The TC-800D-WP 8 channel Data Logger employs cutting-edge microcontroller technology, offering superior accuracy for diverse applications. With 8 fixed input channels as per customer requirement of a specific input supporting various thermocouples (J, K, R, S, T, E, B, N), RTD (PT-100), and either 4-20mA or 0-10 VDC inputs, this logger ensures versatility. User-programmable features include channel scan time (1 to 59 sec), logging intervals (1 to 9999 sec), and temperature readings in both °C and °F. Field calibration is convenient with a front-panel membrane keypad, and automatic cold junction compensation is provided for thermocouples. The logger supports ISO certification records and facilitates pharmaceutical process validation with detailed graph and Excel reports for autoclaves. It’s ideal for applications such as oven profiling, BOD monitoring, generator temperature tracking, and heat profile analysis in furnaces and foundries.

1. Advanced Technology: 8 channel Data Logger utilizes the latest microcontroller-based technology for enhanced accuracy in temperature and humidity monitoring.

2. Versatile Input Support: 8 channel Data Logger features 8 fixed input channels as per customer requirement of a specific input supporting various thermocouples (J, K, R, S, T, E, B, N), RTD (PT-100), and either 4-20mA, or 0-10 VDC, offering flexibility for different applications.

3. User-Programmable Settings: Allows easy online field calibration through a front-panel membrane keypad, empowering users to customize channel scan times (1 to 59 sec) and logging intervals (1 to 9999 sec).

4. Temperature Readout Options: Provides temperature readings in both °C and °F, giving users the flexibility to choose their preferred unit of measurement.

5. Cold Junction Compensation: Automatic compensation for thermocouples’ cold junctions enhances accuracy in temperature monitoring.

6. Alarm Indications: Equipped with 8 red LEDs (3 mm) for clear alarm indications (Al1 & Al2) and supports two independent set points with programmable latch/non-latch functionality.

7. Control Logic Options: Offers HI-LO, LO-Very LO, and HI-Very HI control action logic, allowing users to tailor the control system to their specific needs.

8. Reliable Relay Outputs: Features 1 NO/C/NC relay contact for Relay-1 (AL1) and Relay-2 (AL2), each rated at 230VAC/5A, ensuring dependable control and alarm functionalities.

9. Large LED Display: Incorporates a 4-digit 13 mm red LED display for process value indication and a 1-digit 13 mm red LED display for channel number indication.

Technical Specifications:

1. Scan Time: Programmable scan time between channels, ranging from 0 to 59 seconds.

2. Logging Interval: User-programmable logging interval for data logger model, ranging from 1 to 9999 seconds.

3. Memory Capacity: Data logger model has a maximum memory capacity of 5192 readings for all 8 channels, supporting memory saturation, scrolling, and online PC interface.

4. Operating Voltage: Supports a wide supply voltage range of 100 to 270VAC, ensuring compatibility with various power systems.

5. Environmental Conditions: Operates in harsh conditions with an operating temperature range of -40 to 85°C and a relative humidity below 95% RH (non-condensing)

6. Optional Features:

– RS-485/RS-232 Modbus Serial Port with MODBUS RTU Protocol output.

– Compatibility with SMARTLOG & Smart Pro Data Acquisition Software for online graphs and historical data reports.

– Individual or grouped relay outputs can be configured for each channel.

7. Weatherproof Housing:

– Protection Class: IP65.

– Cabinet Material: ABS Plastic.

– Cable Entry: Thermoplastic Cable Gland (IP 68) with a clamping range of 2.5 to 6.5 mm.

– Dimensions: 368 mm (H) x 290 mm (W) x 112 mm (D).

– Mounting: Wall Mounting/Stand Mounting.

– Weight: Approximately 2.5 Kg.

| Industrial & Human Safety | ISO Certification & Validation |

| Pharmaceutical Autoclaves | Environmental Monitoring |

| Winding Temperature Control | Heat Profile in Furnaces & Foundries |

| Boiler Temperature Scanning | Chemical & Hazardous Area Data Monitoring |

| Room Mapping in Pharmaceuticals |